Graphene-based composite negative electrode material and preparation method thereof

A negative electrode material, graphene-based technology, applied in the field of graphene-based composite negative electrode materials and its preparation, can solve the problems of unstable structure, low specific capacity, low tap density, etc., achieve good adhesion and reduce specific surface area , the effect of thin coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

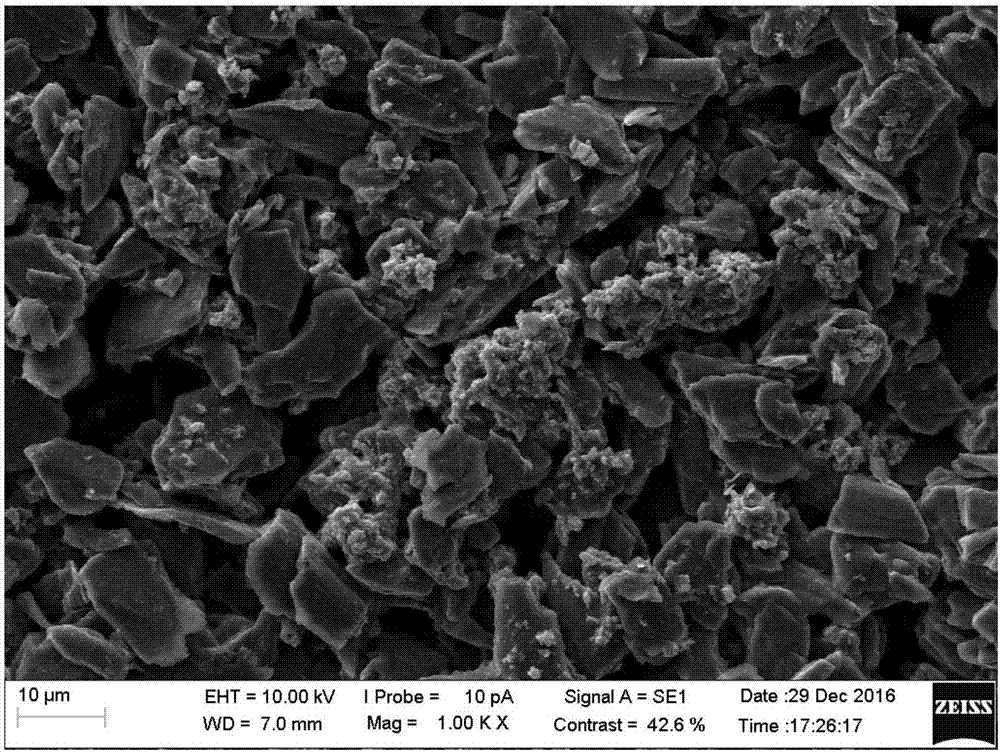

Image

Examples

Embodiment 1

[0036] The preparation method of the graphene-based composite negative electrode material of the present embodiment comprises the following steps:

[0037] (1) To 1000mL of graphene oxide dispersion with a concentration of 10mg / mL, add 5mL of hydrogen peroxide with a mass fraction of 10% and 0.375g of pyrrole and mix evenly, then add 3.75g of methyl orthosilicate material and mix evenly , to get a mixed solution;

[0038] (2) Put the mixed solution in step (1) in a high-pressure reactor and conduct a hydrothermal reaction at 180°C for 6 hours. After cooling, filter, dry, and press into tablets, and then heat up to 850°C in an argon atmosphere for carbonization for 3 hours. , and then naturally cooled to room temperature to obtain a nitrogen-doped graphene and silicon dioxide composite material;

[0039] (3) Dissolve 1g of polyvinylpyrrolidone in 100mL of twice-distilled water and disperse evenly to obtain a solution of polyvinylpyrrolidone; dissolve 1g of polystyrenesulfonic ...

Embodiment 2

[0042] The preparation method of the present embodiment comprises the steps:

[0043] (1) To 1000mL of graphene oxide dispersion with a concentration of 5mg / mL, add 1mL of hydrogen peroxide with a mass fraction of 30% and 0.25g of melamine and mix evenly, then add 2.5g tetraethyl orthosilicate material and mix evenly , to get a mixed solution;

[0044] (2) Put the mixed solution in step (1) in a high-pressure reactor and conduct a hydrothermal reaction at 180°C for 6 hours, after cooling, filter, dry, press into tablets, and then carbonize in an argon atmosphere, wherein the carbonization conditions are : Raise the temperature at a rate of 5°C / min to 550°C for 2 hours, then raise the temperature to 850°C at a rate of 5°C / min and hold for 2 hours, then cool down to room temperature naturally to obtain a nitrogen-doped graphene and silicon dioxide composite material ;

[0045](3) Dissolve 0.1g of polyvinylpyrrolidone in 100mL double distilled water and disperse evenly to obtai...

Embodiment 3

[0048] The preparation method of the present embodiment comprises the steps:

[0049] (1) To 1000mL of graphene oxide dispersion with a concentration of 20mg / mL, add 20mL of hydrogen peroxide with a mass fraction of 1% and 0.67g of urea and mix evenly, then add 6.7g of propyl orthosilicate material and mix evenly , to get a mixed solution;

[0050] (2) Put the mixed solution in step (1) in a high-pressure reactor and conduct a hydrothermal reaction at 180°C for 6 hours, after cooling, filter, dry, press into tablets, and then carbonize in an argon atmosphere, wherein the carbonization conditions are : The temperature was raised to 850°C for 2 hours at a heating rate of 5°C / min, and then naturally cooled to room temperature to obtain a nitrogen-doped graphene and silicon dioxide composite material;

[0051] (3) Dissolve 10g of polyvinylpyrrolidone in 100mL of twice-distilled water, and disperse evenly to obtain a solution of polyvinylpyrrolidone; After uniform dispersion in d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com