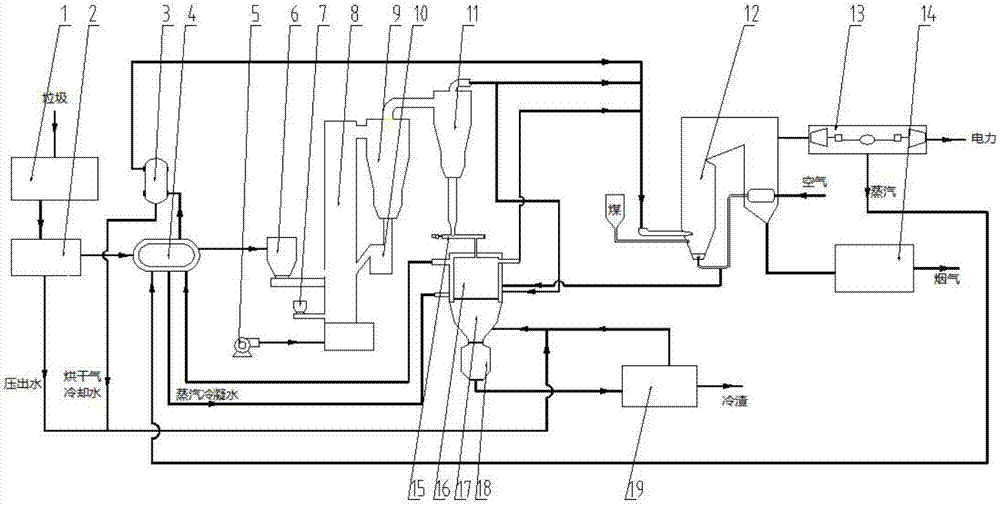

Garbage gasification coupling coal-fired power plant power generating apparatus and power generating process

A coal-fired power station and power generation device technology, which is applied in the direction of gasification process, combined combustion mitigation, petroleum industry, etc., can solve the problems of low slag utilization rate, high equipment investment, groundwater pollution, etc., and achieve the reduction of organic component content, system equipment Low investment and lower melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] After the garbage is sorted by the sorting device, 50% of plastics, 5% of wood chips and paper, 45% of biological and kitchen waste, and a moisture content of 35%. After extrusion, dehydration, granulation and drying, the moisture content is reduced to 20%. density≤3cm, 1.0mm river sand is added to the gasifier from the bed material hopper, 0.8mm dolomite is added according to dolomite:garbage=0.3:1 (kg / kg), the operating temperature of the gasifier is 650°C, and the inner flow of the furnace is controlled The melting speed is 3.5m / s, the melting chamber temperature is 950°C, the steam pressure generated in the melting chamber is 0.75MPa, and the dioxin content in the gas is 0.008ng / Nm3. The high-temperature gas generated by the gasifier and the high-temperature flue gas generated by the melting chamber are sent to the coal-fired boiler for coupling power generation. The temperature of the steam extracted from the steam power generation device is 250°C, and the dioxin co...

Embodiment 2

[0047] After the garbage is sorted by the sorting device, 70% of plastics, 5% of wood chips and paper, 25% of biological and kitchen waste, and a moisture content of 20%. After extrusion, dehydration, granulation and drying, the moisture content is reduced to 9%. Density ≤ 3cm, 0.9mm river sand is added to the gasifier from the bed material hopper, 0.6mm limestone is added according to limestone:garbage=0.6:1 (kg / kg), the operating temperature of the gasifier is 850°C, and the fluidization speed in the furnace is controlled 3.0m / s, the melting chamber temperature is 900°C, the steam pressure generated in the melting chamber is 0.5MPa, and the dioxin content in the gas is 0.01ng / Nm3. The high-temperature gas generated by the gasification furnace and the high-temperature flue gas generated by the melting chamber are sent to the coal-fired boiler for coupled power generation. The slag is sent to building material processing plants or landfills.

Embodiment 3

[0049] After the garbage is sorted by the sorting device, 25% of plastics, 15% of wood chips and paper, 60% of biological and kitchen waste, and a moisture content of 50%. Density ≤ 3cm, 1.5mm river sand is added to the gasifier from the bed material hopper, 1.0mm calcium oxide particles are added according to calcium oxide particles: garbage = 0.2: 1 (kg / kg), the operating temperature of the gasifier is 600°C, and the furnace is controlled The internal fluidization velocity is 3.0m / s, the melting chamber temperature is 1150°C, the steam pressure generated in the melting chamber is 1.0MPa, and the dioxin content in the gas is 0.007ng / Nm3. The high-temperature gas generated by the gasification furnace and the high-temperature flue gas generated by the melting chamber are sent to the coal-fired boiler for coupling power generation. The slag is sent to building material processing plants or landfills.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com