YAG (yttrium aluminum garnet)-type fluorescent powder, preparation method of YAG-type fluorescent powder, YAG-type transparent ceramic fluorescent body prepared from YAG-type fluorescent powder and application of YAG-type transparent ceramic fluorescent body

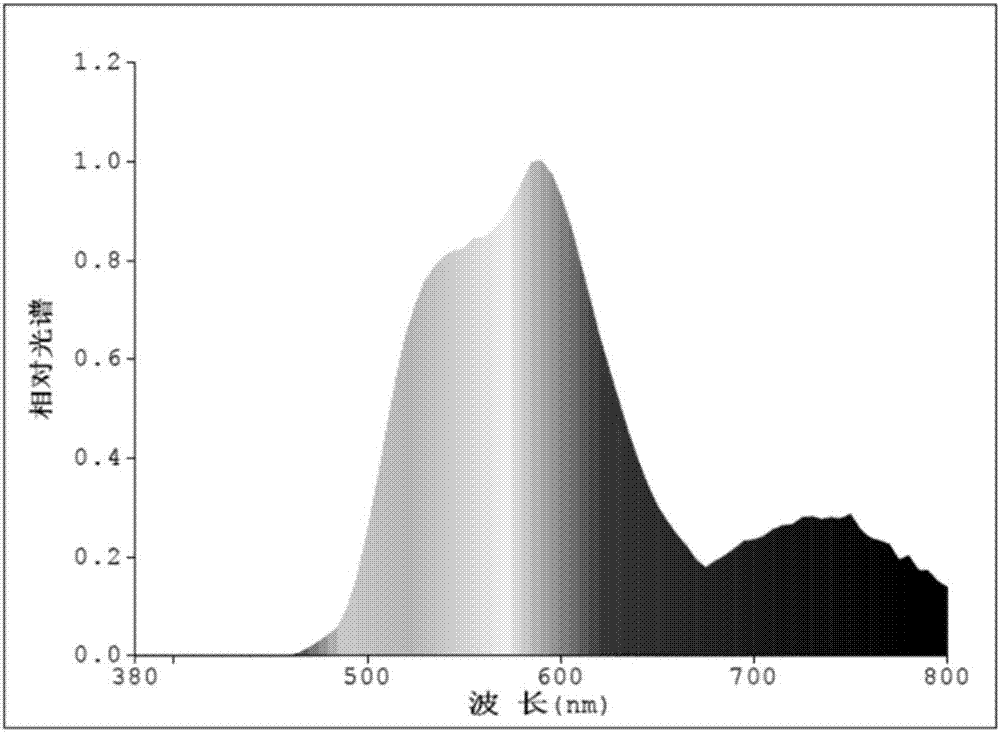

A technology of transparent ceramics and phosphors, which is applied in the field of ceramic materials, can solve the problems of lack of red light components of phosphors and low overall light efficiency, and achieve good stability and anti-light decay performance, high color rendering index and luminous efficiency, Improve the effect of low color rendering index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

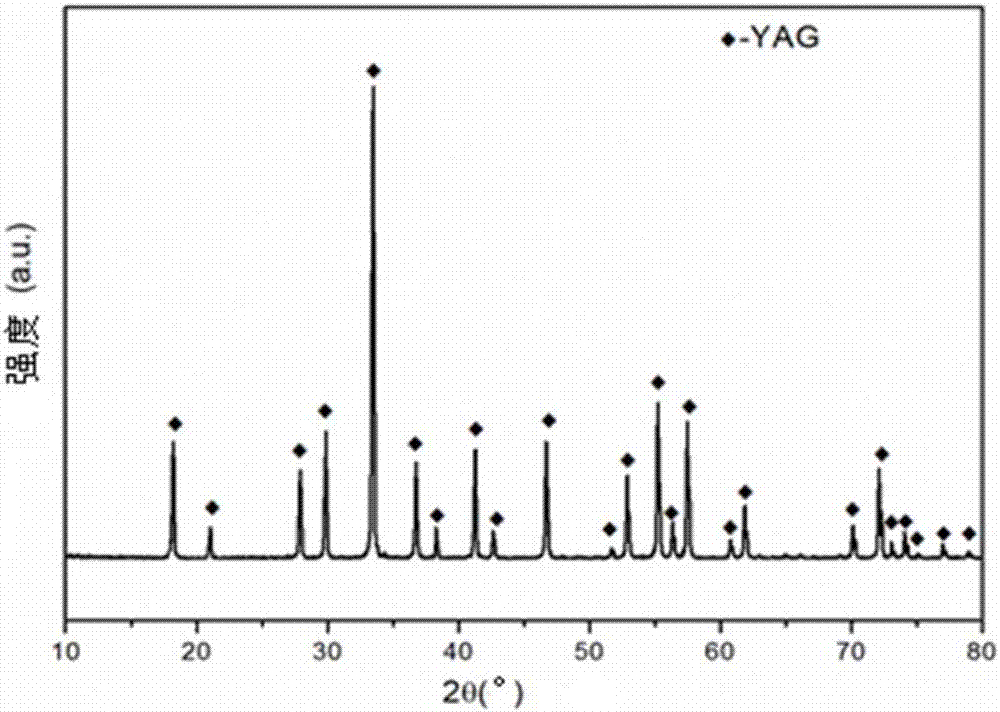

[0072] Example 1 Preparation of YAG-type phosphor sample P01 and YAG-type transparent ceramic phosphor C1

[0073] Using yttrium oxide (Y) with a purity of 99.9% 2 o 3 ), alumina (Al 2 o 3 ), cerium oxide (CeO 2 ), manganese monoxide (MnO), silicon dioxide (SiO 2 ) powder, press Y 2.97 Al 4.85 o 12 :0.03Ce 3+ ,0.075Mn 2+ ,0.075Si 4+ Composition Prepare a total of 50g of raw materials, put the powder in the same container; add 25g of acetone to the container containing the powder, stir the mixed powder thoroughly through mechanical stirring, and place the mixed slurry in a rotary evaporator to evaporate quickly Remove acetone, dry in a drying oven at 80°C for 5 hours and then sieve; put the sieved mixture into a crucible, 2 / H 2 (Volume ratio 90:10) atmosphere, in a tube furnace, first raise the temperature to 1000°C at a heating rate of 10°C / min, then raise the temperature to 1450°C at a heating rate of 5°C / min, react for 5 hours and then cool naturally , that is,...

Embodiment 2

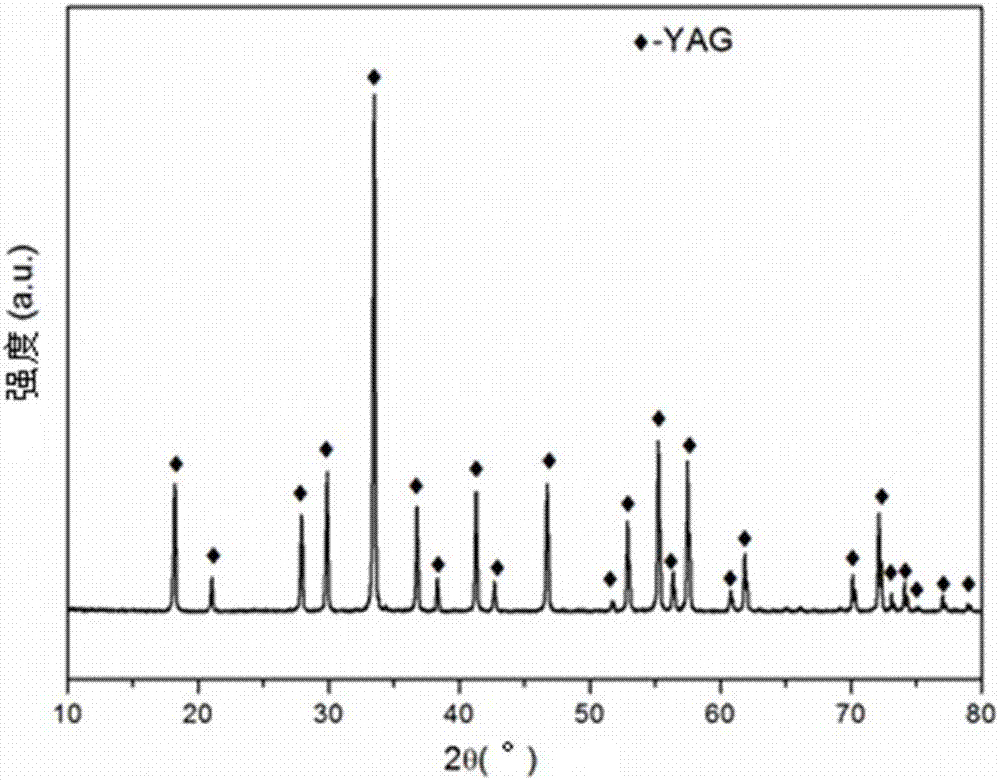

[0075] Example 2 Preparation of YAG-type phosphor sample P02 and YAG-type transparent ceramic phosphor C2

[0076] Using yttrium oxide (Y) with a purity of 99.9% 2 o 3 ), aluminum hydroxide (Al(OH) 3 ), cerium oxide (CeO 2 ), manganese acetate (Mn(C 2 h 3 o 2 ) 2 ), zirconium dioxide (ZrO 2 ) powder, press Y 2.94 Al 4.8 o 12 : 0.06Ce 3+ ,0.1Mn 2+ ,0.1Zr 4+ Composition Prepare a total of 50g of raw materials, put the powder in the same container; add 50g of ethanol to the container containing the powder, mix the powder thoroughly through mechanical stirring, and place the mixed slurry in a rotary evaporator to evaporate quickly Remove the solvent, dry in a drying oven at 80°C for 5 hours and then sieve; put the sieved mixture into a crucible, and put it under flowing N 2 / H 2(Volume ratio is 85:15) atmosphere, in a tube furnace, first raise the temperature to 1000°C at a heating rate of 10°C / min, then raise the temperature to 1500°C at a heating rate of 5°C / min, ...

Embodiment 3

[0078] Example 3 Preparation of YAG-type phosphor sample P03 and YAG-type transparent ceramic phosphor C3

[0079] Using lutetium nitrate (Lu(NO) with a purity of 99.9% 3 ) 3 ), aluminum nitrate (Al(NO 3 ) 3 ), cerium oxide (CeO 2 ), manganese carbonate (MnCO 3 ), titanium dioxide (TiO 2 ) powder, press Y 2.91 Al 4.7 o 12 : 0.09Ce 3+ ,0.15Mn 2+ ,0.15Ti 4+ Composition Prepare a total of 50g of raw materials, put the powder in the same container; add 50g of ether to the container containing the powder, stir the mixed powder thoroughly through mechanical stirring, and place the mixed slurry in a rotary evaporator to evaporate quickly. Remove the solvent, dry in a drying oven at 80°C for 5 hours and then sieve; put the sieved mixture into a crucible, and put it under flowing N 2 / H 2 (Volume ratio 85:15) atmosphere, in a tube furnace, first raise the temperature to 1000°C at a heating rate of 10°C / min, then raise the temperature to 1550°C at a heating rate of 5°C / min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com