Tilmicosin film-controlled enteric-coated sustained release preparation and preparation method thereof

A technology of tilmicosin and sustained-release preparations, which is applied in the direction of pharmaceutical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., which can solve the unfavorable recycling of waste materials and the instability of coated granules , Easy to degrade gastric mucosa and other problems, to achieve the effect of reducing the clinical addition of drugs, improving drug efficacy and bioavailability, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

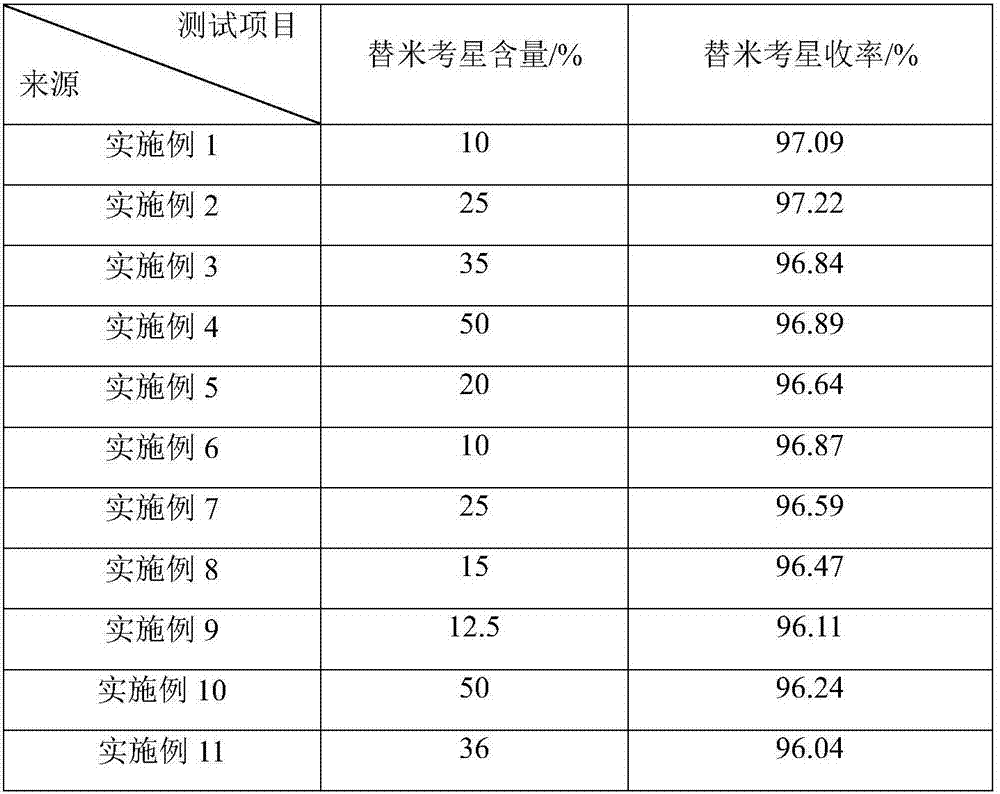

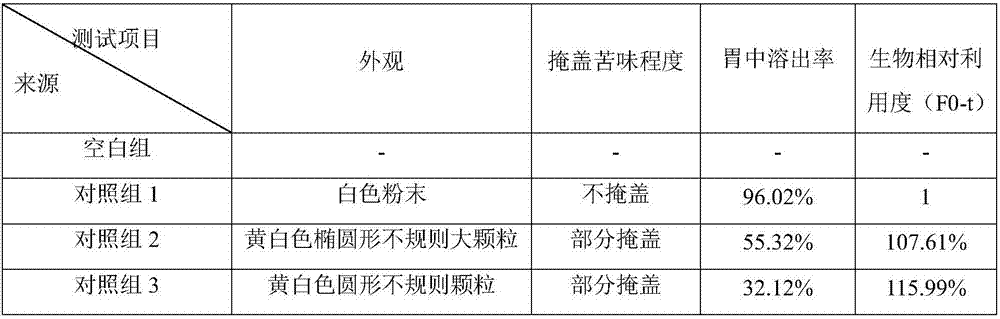

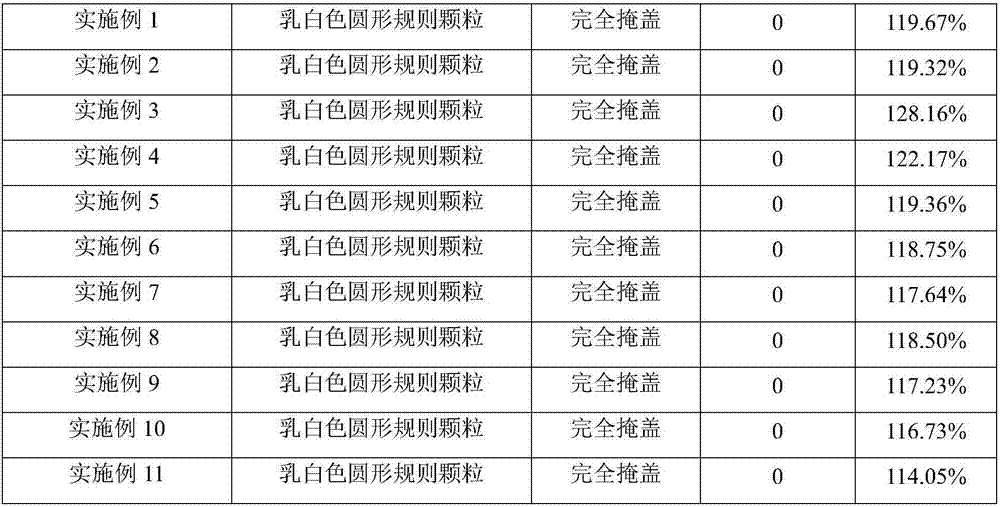

Examples

Embodiment 1

[0036] Tilmicosin film-controlled enteric-coated sustained-release preparation, which consists of:

[0037] Tilmicosin powder 10g;

[0038] Inner layer excipients: starch 57.08g, microcrystalline cellulose 15g, sodium alginate 6.2g, chitin 3.72g, hydroxypropyl methylcellulose 0.12g;

[0039] Film coating layer material: polyvinyl alcohol acetate phthalate 5.72g;

[0040] Excipient materials for film coating layer: 0.16 g of talc powder, 2 g of titanium dioxide.

[0041] The preparation method of tilmicosin film-controlled enteric-coated sustained-release preparation, the specific steps are:

[0042] S1. Mix the original powder of tilmicosin and the excipients of the core layer except hydroxypropyl methylcellulose according to the method of equal increase;

[0043] S2. Dissolving hydroxypropyl methylcellulose in ethanol to prepare an ethanol solution with a mass fraction of 10%;

[0044] S3. Add the mixture obtained in step S1 to the ethanol solution obtained in step S2 to ...

Embodiment 2

[0049] Tilmicosin film-controlled enteric-coated sustained-release preparation, consisting of:

[0050] tilmicosin powder 25g;

[0051] Inner layer excipients: starch 47.08g, microcrystalline cellulose 10g, sodium alginate 6.2g, chitin 3.72g, hydroxypropyl methylcellulose 0.12g

[0052] Film coating layer material: polyvinyl alcohol acetate phthalate 5.72g

[0053] Excipient materials for film coating layer: 0.16 g of talc powder, 2 g of titanium dioxide.

[0054] The preparation method of tilmicosin film-controlled enteric-coated sustained-release preparation, the specific steps are:

[0055] S1. Mix the original powder of tilmicosin and the excipients of the core layer except hydroxypropyl methylcellulose according to the method of equal increase;

[0056] S2. Dissolving hydroxypropyl methylcellulose in ethanol to prepare an ethanol solution with a mass fraction of 10%;

[0057] S3. Add the mixture obtained in step S1 to the ethanol solution obtained in step S2 to make a...

Embodiment 3

[0062] Tilmicosin film-controlled enteric-coated sustained-release preparation, consisting of:

[0063] tilmicosin powder 35g;

[0064] Inner layer excipients: starch 28.84g, povidone 4g, microcrystalline cellulose 15g, sodium alginate 6.2g, chitin 3.72g, hydroxypropyl methylcellulose 0.24g;

[0065] Film coating layer material: polyacrylic acid resin 5g;

[0066] Excipients for the film coating layer: 0.5 g of magnesium stearate, 1.5 g of titanium dioxide.

[0067] The preparation method of tilmicosin film-controlled enteric-coated sustained-release preparation, the specific steps are:

[0068] S1. Mix the original powder of tilmicosin and the excipients of the core layer except hydroxypropyl methylcellulose according to the method of equal increase;

[0069] S2. Dissolving hydroxypropyl methylcellulose in ethanol to prepare an ethanol solution with a mass fraction of 10%;

[0070] S3. Add the mixture obtained in step S1 to the ethanol solution obtained in step S2 to make...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com