Nanometer composite oxygen electrode material and preparation method and application thereof

A nanocomposite, oxygen electrode technology, applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve the problems of high electrode catalyst price, susceptibility to toxicity and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

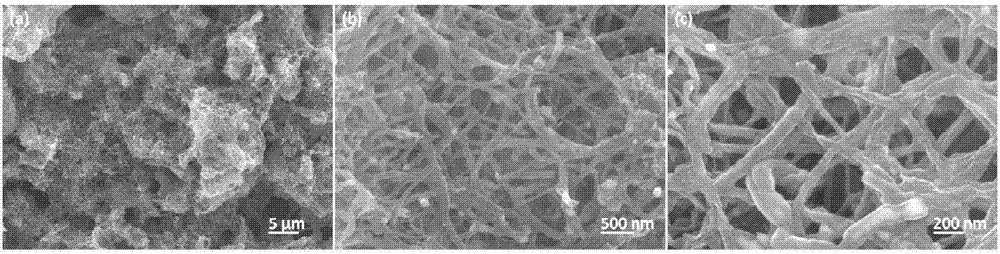

[0041] like figure 1 As shown, the nanocomposite oxygen electrode material is a bifunctional N-CNTs / Ni composite material, which is prepared by a one-step high-temperature calcination synthesis method. Simply put, nickel nitrate, melamine, and glucose are mixed into a certain amount of distilled water, and stirred to make the three substances evenly mixed, and then evaporated and dried. Subsequently, the dried precursor was placed in a tube furnace and calcined in a nitrogen atmosphere at 800 °C. When the temperature reaches 500°C, the metal salt begins to decompose and transform into elemental metal particles; at the same time, melamine transforms into layered graphite-like carbon three nitrogen four (g-C 3 N 4 ), while the glucose is transformed into graphitic carbon, and the two carbon materials are layered on top of each other in a stacked fashion. When the temperature reaches 800℃, g-C 3 N 4 It is decomposed into small fragments containing C and N elements, and the g...

Embodiment 2

[0045] Defects on the N-CNTs / Ni surface are formed during the synthesis process. When the temperature reaches 500 degrees Celsius, glucose decomposes and turns into graphitic carbon, while melamine turns into g-C 3 N 4 . When the temperature is further increased to 800°C, g-C 3 N 4 Further breaks down into small pieces and provides an element-rich source of C and N. At the same time, based on the catalytic effect of the metal particles, various carbon fragments reintegrate to grow carbon nanotubes. During the catalytic reaction using FeCo metal particles as the catalytic source, a large number of oxygen-containing functional groups are embedded in the carbon fragments. At this time, the carbon atoms bonded to the oxygen atoms cannot be sp 2 The covalent bond pattern binds to other carbon atoms, thus, defects are created in the disconnected carbon atoms. In addition, the N atoms strongly coordinated with the metal nanoparticles are also simultaneously doped into the carbo...

Embodiment 3

[0048] In order to further test the practicability of N-CNTs / Ni, N-CNTs / Ni was made into an oxygen electrode and applied to a zinc-air battery to observe its electrode performance ( Figure 12). The test results show that the Zn-air battery with N-CNTs / Ni as oxygen electrode has the same resistance as that of Pt / C-IrO 2 The similarity indicates that the working environment of the two is similar. The open circuit potential test shows that the open circuit potential of the zinc-air battery with N-CNTs / Ni as the oxygen electrode is comparable to that of Pt / C-IrO 2 close to. The discharge test results show that the discharge polarization curve of the zinc-air battery with N-CNTs / Ni as the oxygen electrode is similar to that of Pt / C-IrO 2 are similar, and the overpotential values of the two are similar; while the power density of N-CNTs / Ni is that of Pt / C-IrO 2 91.5%. Further discharge tests show that N-CNTs / Ni has the same properties as Pt / C-IrO 2 Similar specific capacita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com