Ultrasonic detecting device for building steel structure

An ultrasonic testing and testing device technology, applied in measuring devices, using sonic/ultrasonic/infrasonic waves to analyze solids, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. Detection and other problems to achieve the effect of avoiding interference and pollution, real-time detection, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

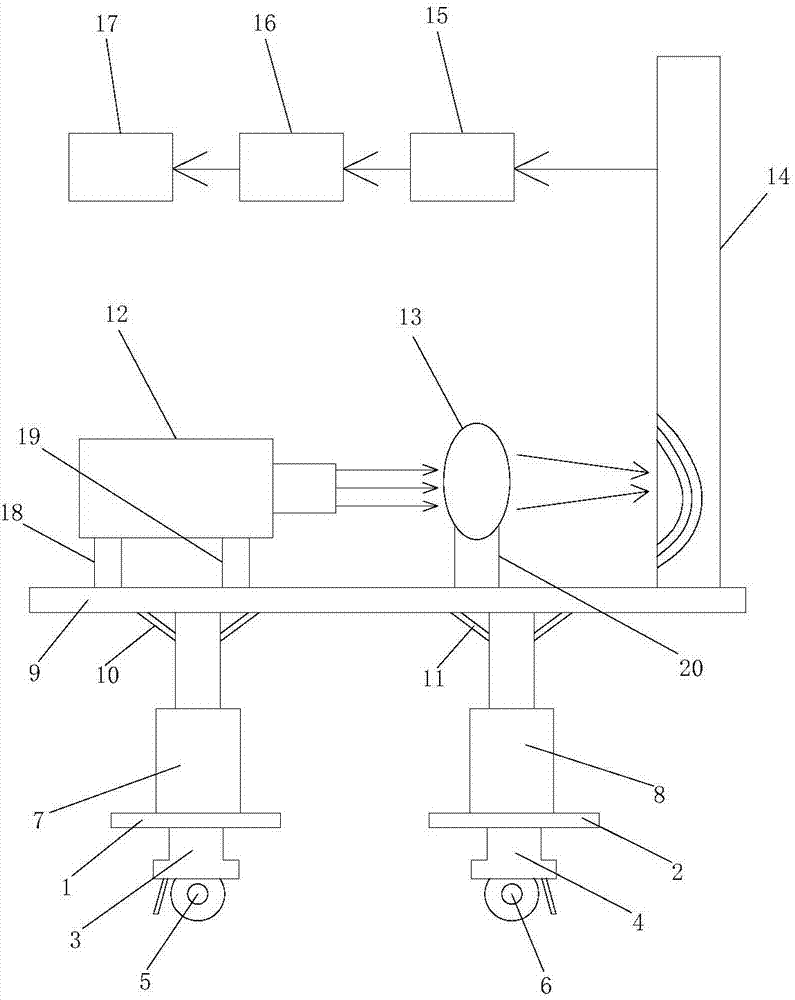

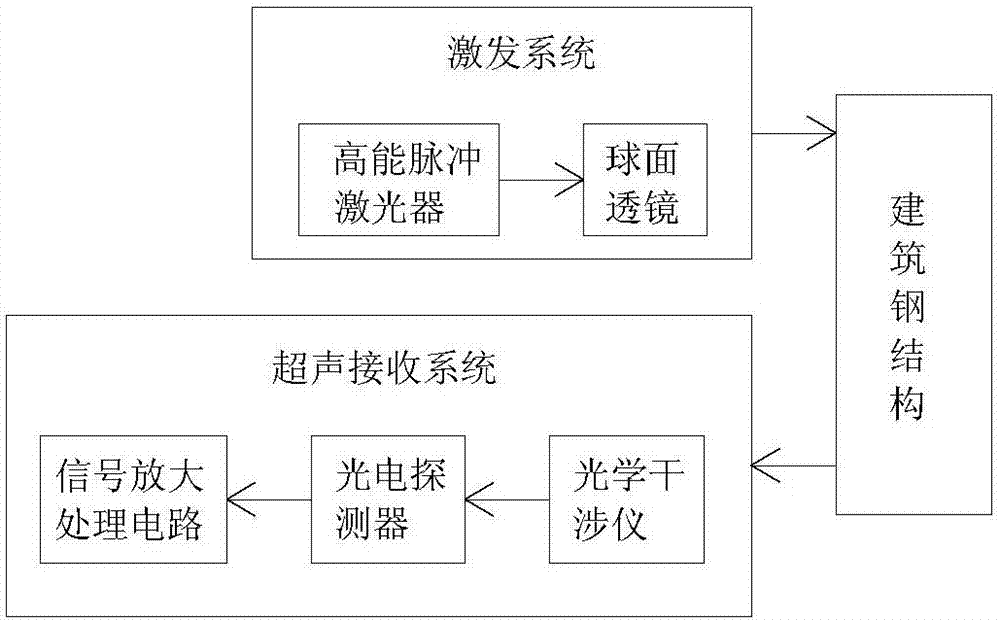

[0015] see figure 1 and figure 2 , a kind of building steel structure ultrasonic detection device, the detection device includes an excitation system and an ultrasonic receiving system, the excitation system includes a high-energy pulse laser 12, a spherical lens 13, and the high-energy pulse laser 12 is used for detecting High heat is generated on the building steel structure 14, thereby generating a pulse signal, and the laser beam produced by the high-energy pulse laser 12 is focused on the surface of the building steel structure 14 through a spherical lens 13 to form a point source; the ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com