Preparation method of graphene-copper-amorphous composite coating

A composite coating, graphene technology, applied in the direction of coating, metal material coating process, metal processing equipment, etc., to achieve the effect of reducing the amount of wear, reducing the coefficient of friction, and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

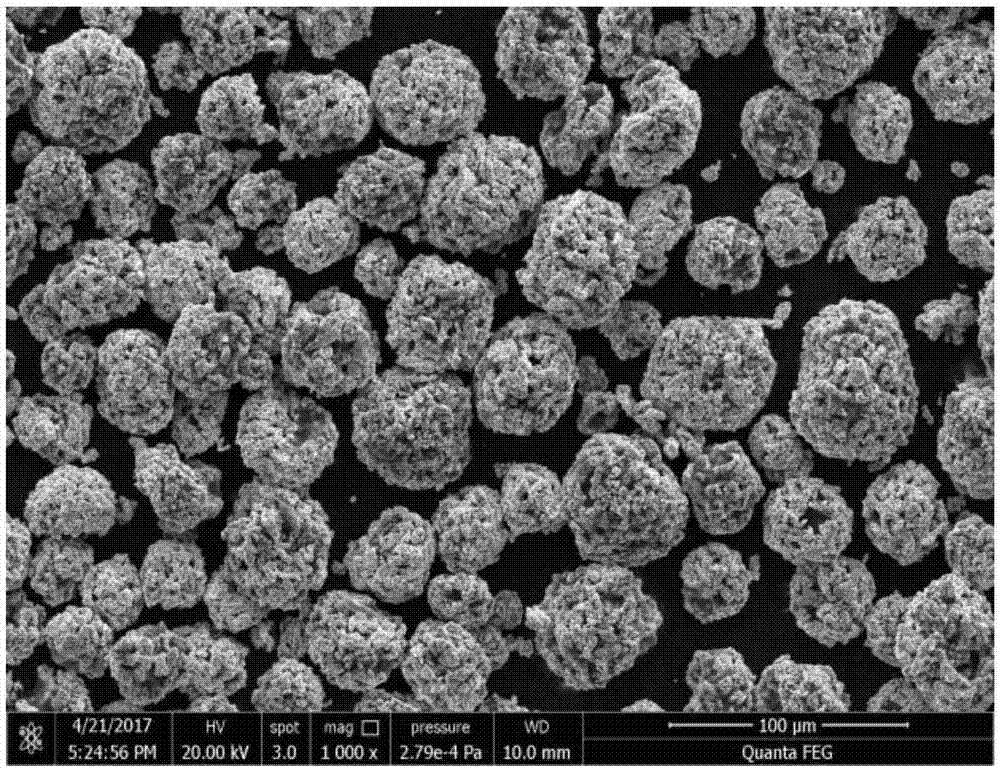

[0040] Embodiment 1 adopts atomization method to prepare graphene-copper composite powder

[0041] The embodiment of the present invention adopts the following technical conditions

[0042](1) The mass ratio of sodium carboxymethyl cellulose and deionized water is 1:1000 in a water bath, heated at 95° C. and mechanically stirred for about one hour until viscous, and the binder is obtained.

[0043] (2), according to the composite powder of copper powder and graphene oxide powder, metal powder accounts for 98wt.%, and graphene oxide powder accounts for the ratio of 2wt.%, weigh copper powder and graphene oxide powder. Taking the sum of the graphene powder and the copper powder quality as the total mass of the powder, the binder prepared by (1) is 50% of the total mass of the powder, the dispersant accounts for 1.5% of the total mass of the powder, and the mass of deionized water is A slurry was prepared for 130% by mass of all powders. Among them, the dispersant is sodium pol...

Embodiment 2

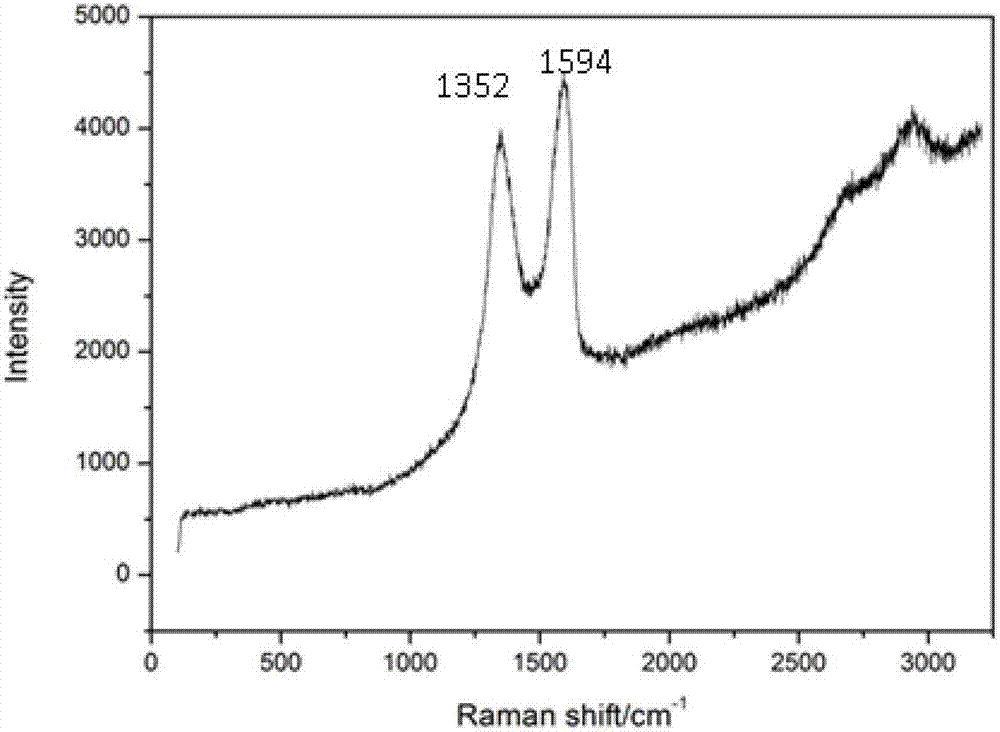

[0048] Example 2 The other steps of the method for preparing graphene-copper composite powder in this example are the same as in Example 1, except that the ratio of graphene to copper powder is different in this example. In the composite powder of copper powder and graphene oxide powder, the metal powder accounts for 95wt.%, and the graphene oxide powder accounts for 5wt.%. The obtained composite powder is spherical in shape. The D and G peaks of graphene can be detected by Raman spectroscopy.

Embodiment 3

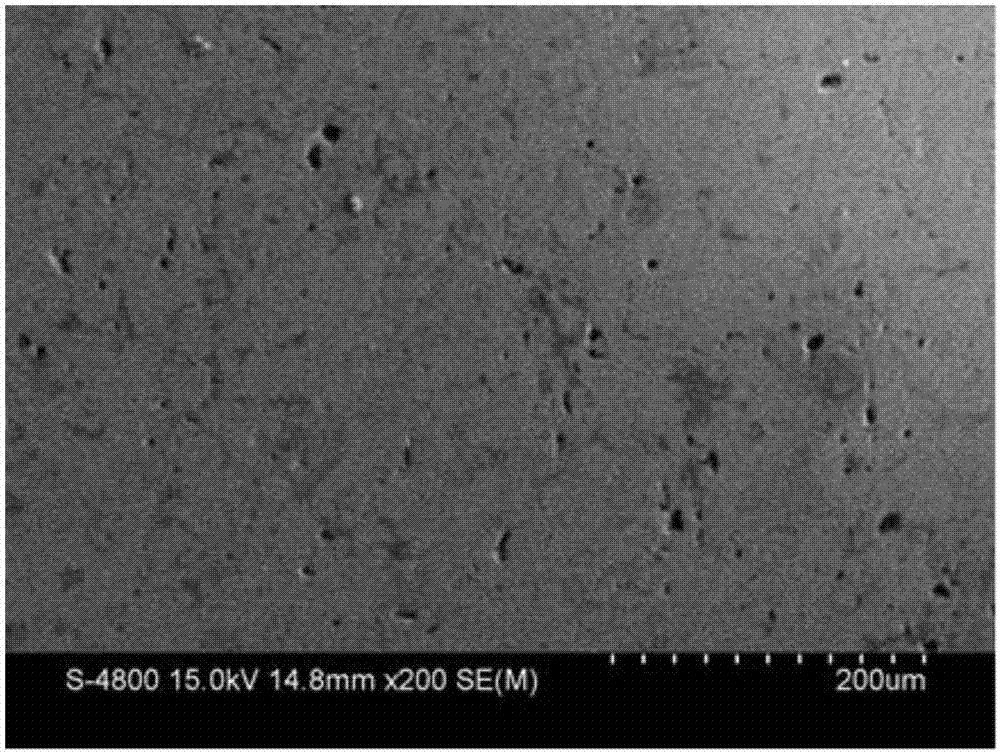

[0049] Example 3 The substrate is 45# steel, and a graphene-copper complex-iron-based amorphous composite coating is prepared by plasma spraying technology.

[0050] In the present invention, the graphene-copper composite powder in Example 1 is used as one of the spraying feed powders and mixed with the amorphous powder to obtain the mixed feed powder.

[0051] The first step is to prepare graphene-copper-iron-based amorphous mixed feed powder

[0052] The weight ratio of graphene-copper composite powder and iron-based amorphous powder is 1:19, and the two powders are mechanically mixed for 4 hours to obtain graphene-copper-iron-based amorphous mixed feed powder. The iron-based amorphous powder is a commercially available product, and its composition is: Cr: 25%-27%, C: 2%-2.5%, Mo: 16%-18%, B: 2%-2.2%, and the balance It is Fe, the above ratios are all percentages by mass, and the powders are all spherical or nearly spherical particles with a particle size of 10-70 μm.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com