Environment-friendly and oil-resistant rubber for sealing

An oil-resistant rubber and sealing technology, applied in the rubber field, can solve the problems of human health hazards, short service life, ozone cracking, etc., and achieve the effects of vulcanization pollution resistance, high wear resistance and promoting melting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of environment-friendly oil-resistant rubber for sealing in this embodiment is made of the following raw materials in parts by mass: nitrile rubber 50-70, stabilizer 8-15, modified chloroprene rubber 20-50, carbon black 20- 30, polystyrene 8-12, vulcanizing agent 1-1.5, additive 15-20, stearic acid 3-4, zinc oxide 5-10, magnesium oxide 12-18, antioxidant 10-14, paraffin 10-20;

[0031] Its preparation method comprises the following steps:

[0032] Step S1: Weigh nitrile rubber, stabilizer, zinc oxide, magnesium oxide, stearic acid, paraffin, and polystyrene according to the weight parts of the raw materials and mix them, put the mixed raw materials in a high-speed blender, and Stir at 100-140°C for 15-25 minutes;

[0033] Step S2: Thin pass 10 times, then add anti-aging agent and 1 / 2 part of carbon black in raw materials for mixing;

[0034] Step S3: thin pass 10 times, then add modified chloroprene rubber, additives, and carbon black in the remaining amount of...

Embodiment 2

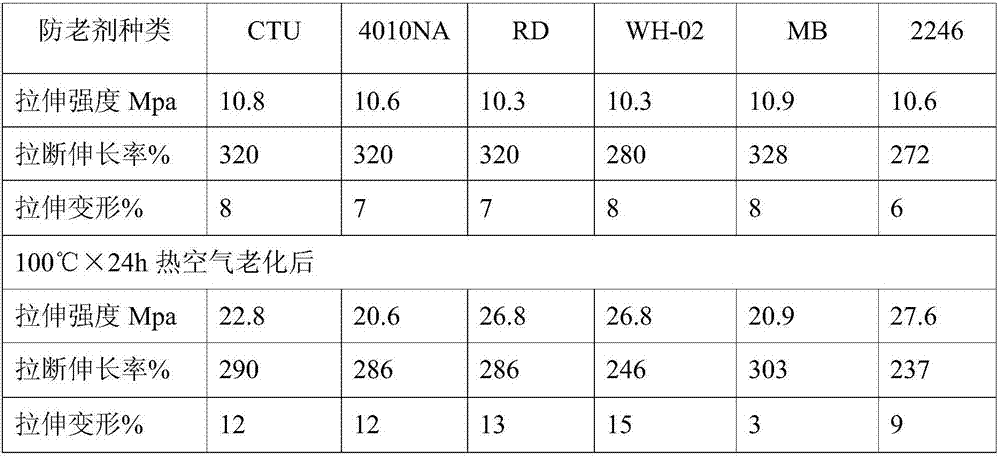

[0039] This embodiment is further optimized on the basis of embodiment 1, and the anti-aging agent is CTU anti-aging agent. As shown in Table 1: Change parameters of CTU antioxidant under normal conditions and after aging in hot air at 100°C×24h.

[0040]

[0041] Table 1

[0042] Analyzing the data in Table 1, in terms of tensile strength and elongation at break, the value of CTU rubber compound containing antioxidant is equivalent to that of MB rubber compound containing antioxidant, and higher than that of rubber compound containing other antioxidants used in the test. The chemical name of anti-aging agent MB is 2-mercaptobenzimidazole, and its structure contains double bonds. During the vulcanization process, MB reacts chemically with rubber, and is chemically bonded in the rubber macromolecular network, so that the rubber compound exhibits Good tensile properties. The structure of anti-aging agent CTU also contains carbon-sulfur double bonds, showing performance simi...

Embodiment 3

[0045] This embodiment is further optimized on the basis of Example 2. The stabilizer is composed of 40-50 calcium stearate, 20-25 zinc stearate, and 30-60 B diketone in parts by weight. Phosphite 40-70, antioxidant 10-15, hydrotalcite 5-8, OPE15-20, EBS10-20 composition.

[0046] The stabilizer obtained according to this formula has good dispersibility, compatibility, processing fluidity, wide adaptability, and excellent surface finish of the product; excellent thermal stability, small initial hue, and no precipitation; does not contain heavy metals and other toxic substances Composition, no vulcanization phenomenon; Congo red has a long test time, excellent electrical insulation, no impurities, and high-efficiency weather resistance; wide application range, strong practicability, less dosage, and multi-functionality; in white products, white better than its similar products. It not only has good compatibility and viscosity control, but also can provide good initial coloring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com