Copper/tin nano composite powder active solder and preparation method thereof

A technology of active solder and composite powder, which is applied in welding equipment, welding/cutting media/materials, welding media, etc., can solve the problems of high temperature resistance connection, slow reaction kinetics, and high connection temperature of chips and electronic devices. Achieve the effects of easy quality control, small thermal-mechanical damage, and low connection temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

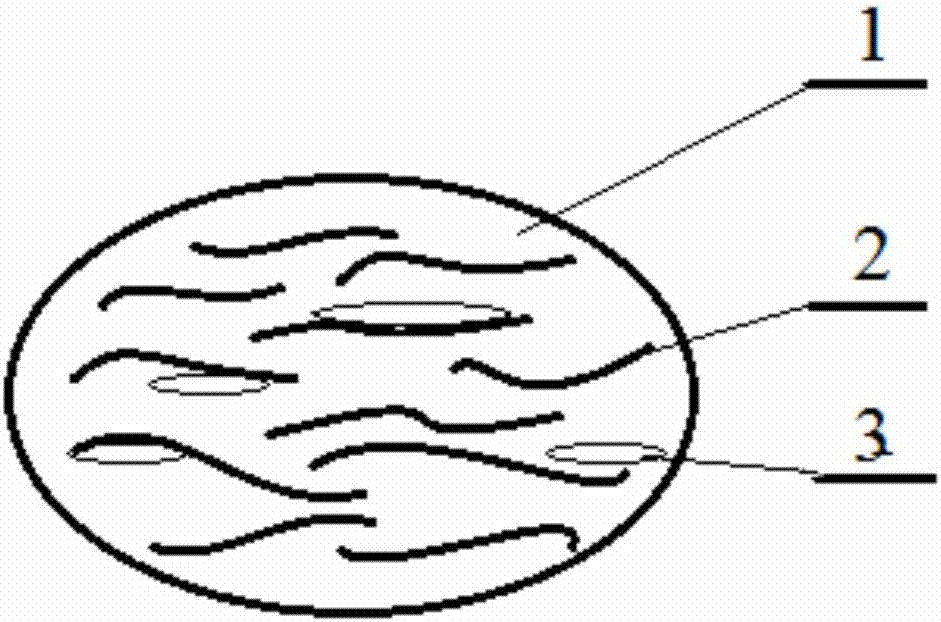

Image

Examples

Embodiment 1

[0025] 1) Preparation of raw material powder. Weigh the tin powder (purity 99.9%, particle size 150 mesh) and copper powder (purity 99.9%, particle size 200 mesh) copper and tin powder at a molar ratio of 1:1, and mix them together.

[0026] 2) High-energy ball milling. Put the mixed metal powder prepared in step 1) into a stainless steel ball mill tank together with stainless steel balls at a ball-to-material ratio of 15:1 (mass ratio), cover and seal, and vacuum to 1×10 with a mechanical pump -1 After Pa, close the vacuum valve, fill the tank with argon to 1 atm, close the vacuum valve, repeat the vacuum-filling process 3 times, and then start the ball mill, the ball mill speed is 300 rpm, and the ball mill time is 4 hours.

[0027] 3) Connect, cold press the powder obtained in step 2) into a sheet of solder, the pressure is 300MPa, and the thickness of the solder sheet is 0.6mm. Place the solder sheet between the two copper plates to be connected and fix it with a clamp. Put t...

Embodiment 2

[0030] 1) Preparation of raw material powder. Weigh the tin powder (purity 99.9%, particle size 150 mesh) and copper powder (purity 99.9%, particle size 200 mesh) copper and tin powder at a molar ratio of 2:1 and mix them together.

[0031] 2) High-energy ball milling. Put the mixed metal powder prepared in step 1) into a stainless steel ball mill tank together with stainless steel balls at a ball-to-material ratio of 15:1 (mass ratio), cover and seal, and vacuum to 1×10 with a mechanical pump -1 After Pa, close the vacuum valve, fill the tank with argon to 1 atm, close the vacuum valve, repeat the vacuum-filling process 3 times, then start the ball mill, the ball mill speed is 200 rpm, and the ball mill time is 0.5 hours.

[0032] 3) Connect, cold press the powder obtained in step 2) into a sheet of solder, the pressure is 100MPa, and the thickness of the solder sheet is 0.2mm. Place the solder sheet between the two copper plates to be connected and fix it with a clamp. Put the ...

Embodiment 3

[0035] 1) Preparation of raw material powder. Weigh the tin powder (purity 99.9%, particle size 150 mesh) and copper powder (purity 99.9%, particle size 200 mesh) copper and tin powder at a molar ratio of 3:1, and mix them together.

[0036] 2) High-energy ball milling. Put the mixed metal powder prepared in step 1) into a stainless steel ball mill tank together with stainless steel balls at a ball-to-material ratio of 15:1 (mass ratio), cover and seal, and vacuum to 1×10 with a mechanical pump -1 After Pa, close the vacuum valve, fill the tank with argon to 1 atm, then close the vacuum valve, repeat the vacuum-filling process 3 times, then start the ball mill, the ball mill speed is 400 rpm, and the ball mill time is 8 hours.

[0037] 3) Connect, cold press the powder obtained in step 2) into a sheet of solder, the pressure is 200MPa, and the thickness of the solder sheet is 0.4mm. Place the solder sheet between the two copper plates to be connected and fix it with a clamp. Put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com