Ultrathin ultra-transparent full-biodegrade film blowing level material and preparation method thereof

A degradable film and all-biological technology, applied in the field of materials, can solve the problems of decreased tensile strength and tear strength, large haze, and difficult opening of film bubbles, and achieve good processing performance and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

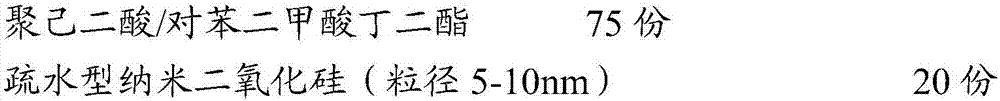

[0026] An ultra-thin and ultra-transparent fully biodegradable film blown film grade material, the main components of which are calculated by weight:

[0027] 87 parts of polyadipate / butylene terephthalate, 10 parts of polylactic acid, 3 parts of reinforced, toughened and anti-reflective masterbatch for ultra-thin and ultra-transparent fully biodegradable film;

[0028] Wherein said poly(butylene adipate / terephthalate) is used as carrier resin, its melt flow rate is 5g / 10min, and hydroxyl value is less than 15; Described polylactic acid melt flow rate is 2.5g / 10min;

[0029] The preparation method of the ultra-thin ultra-transparent fully biodegradable film blown film grade material is as follows:

[0030] Put polyadipate / butylene terephthalate, polylactic acid, and ultra-thin ultra-transparent fully biodegradable film special reinforced, toughened and anti-reflective masterbatches into a high-speed mixer at a stirring speed of 700-1000r / min for 5-8 minutes; The uniformly mix...

Embodiment 2

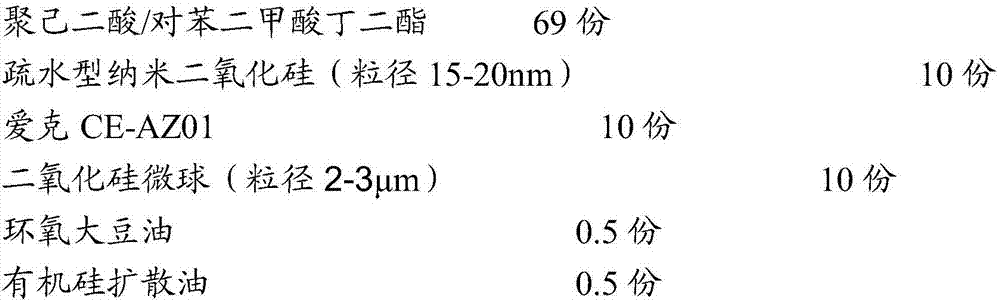

[0038] An ultra-thin and ultra-transparent fully biodegradable film blown film grade material, the main components of which are calculated by weight:

[0039]85 parts of polyadipate / butylene terephthalate, 10 parts of polylactic acid, 5 parts of reinforced, toughened and anti-reflective masterbatch for ultra-thin and ultra-transparent fully biodegradable film;

[0040] Wherein said poly(butylene adipate / terephthalate) is used as carrier resin, its melt flow rate is 5g / 10min, and hydroxyl value is less than 15; Described polylactic acid melt flow rate is 2.5g / 10min;

[0041] The preparation method of the ultra-thin ultra-transparent fully biodegradable film blown film grade material is as follows:

[0042] Put polyadipate / butylene terephthalate, polylactic acid, and ultra-thin ultra-transparent fully biodegradable film special reinforced, toughened and anti-reflective masterbatches into a high-speed mixer at a stirring speed of 700-1000r / min for 5-8 minutes; The uniformly mixe...

Embodiment 3

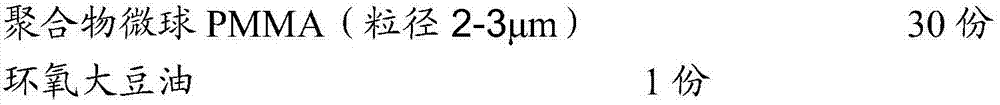

[0049] An ultra-thin and ultra-transparent fully biodegradable film blown film grade material, the main components of which are calculated by weight:

[0050] 90 parts of polyadipate / butylene terephthalate, 5 parts of polylactic acid, 5 parts of reinforced, toughened and anti-reflective masterbatch for ultra-thin and ultra-transparent fully biodegradable film;

[0051] Wherein said polyadipate / butylene terephthalate is used as carrier resin, and its melt flow rate is 5g / 10min; Described polylactic acid melt flow rate is 2.5g / 10min;

[0052] The preparation method of the ultra-thin ultra-transparent fully biodegradable film blown film grade material is as follows:

[0053] Put polyadipate / butylene terephthalate, polylactic acid, and ultra-thin ultra-transparent fully biodegradable film special reinforced, toughened and anti-reflective masterbatches into a high-speed mixer at a stirring speed of 700-1000r / min for 5-8 minutes; The uniformly mixed mixture is put into a twin-screw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com