Junction for copper terminal and aluminium conductor and ultrasonic welding method thereof

A technology of ultrasonic welding and copper terminals, which is applied in the field of wire harnesses, can solve the problems that the industrial preparation of copper terminals and aluminum wire joints cannot be applied, the electrical and mechanical performance requirements of the joints cannot be guaranteed, and the industrial production and application of large quantities cannot be achieved. The performance improvement of electrochemical corrosion and metal corrosion resistance, the improvement of drawing force, the effect of mechanical and electrical performance guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1 A joint of copper terminal and aluminum wire and its ultrasonic welding method

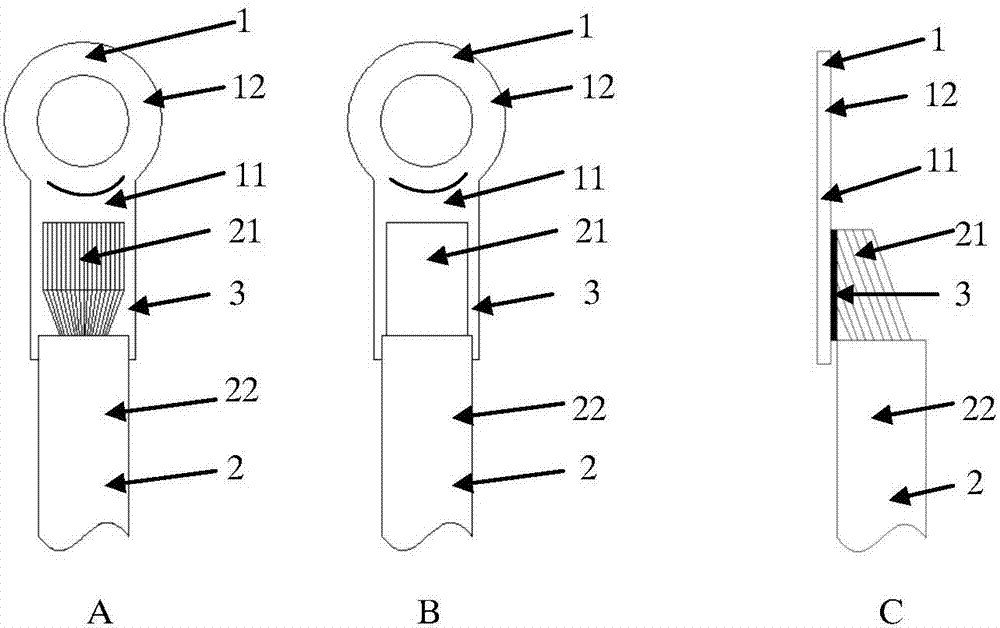

[0068] Such as figure 1 The joint of the copper terminal and the aluminum wire is shown, the copper terminal 1 is a flat copper terminal, the copper terminal 1 includes a connecting part 11, and a functional part 12, the aluminum wire 2 includes a conductor core 21 and an insulating layer 22, and the aluminum wire It is a multi-core aluminum wire ( figure 1 A) or solid aluminum wire ( figure 1 B). The lead core of the aluminum wire 2 is connected to the connecting piece 11 of the copper terminal 1 , and an interval metal layer 3 is included between the lead core of the aluminum lead and the connecting piece of the copper terminal.

[0069] The specific welding steps of the joint are as follows:

[0070] 1) The copper terminal is plated with a spacer metal layer (nickel in this embodiment) in the welding area, and the thickness of the spacer metal layer is 8 μm.

[0071] 2)...

Embodiment 2

[0073] Embodiment 2 A joint of copper terminal and aluminum wire and its ultrasonic welding method

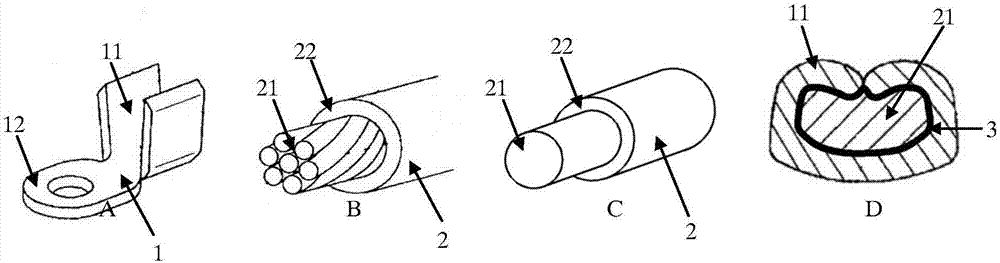

[0074] Such as figure 2 As shown in the joint between the copper terminal and the aluminum wire, the copper terminal 1 is an open terminal, the copper terminal 1 includes a connecting part 11, and a functional part 12, the aluminum wire 2 includes a conductor core 21 and an insulating layer 22, and the aluminum wire is Multi-core aluminum wire ( figure 2 B) or solid aluminum wire ( figure 2 C). The guide core 21 of the aluminum wire 2 is connected to the connecting piece 11 of the copper terminal 1 , and an interval metal layer 3 is also included between the guide core of the aluminum wire and the connecting piece of the copper terminal.

[0075] The specific welding steps of the joint are as follows:

[0076] 1) The copper terminal is electroplated with a spacer metal layer (zinc in this embodiment) in the welding area, and the thickness of the spacer metal layer is 5 μ...

Embodiment 3

[0080] Embodiment 3 A joint of copper terminal and aluminum wire and its ultrasonic welding method

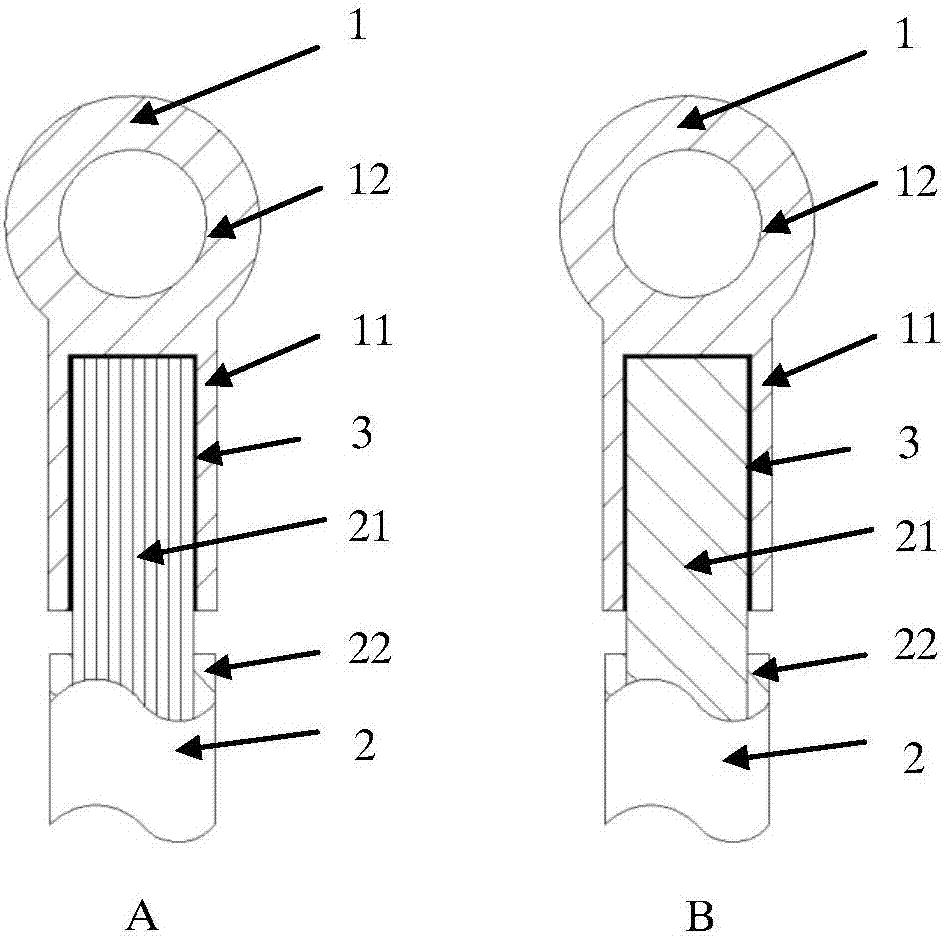

[0081] Such as image 3 As shown in the joint between the copper terminal and the aluminum wire, the copper terminal 1 is a cylindrical terminal, the copper terminal 1 contains a connecting part 11, and a functional part 12, the aluminum wire 2 contains a conductor core 21 and an insulating layer 22, and the aluminum wire It is a multi-core aluminum wire ( image 3 A) or solid aluminum wire ( image 3 B). The guide core 21 of the aluminum wire 2 is connected to the connecting piece 11 of the copper terminal 1 , and an interval metal layer 3 is also included between the guide core of the aluminum wire and the connecting piece of the copper terminal.

[0082] The specific welding steps of the joint are as follows:

[0083] 1) The copper terminal is plated with a spacer metal layer (silver in this embodiment) in the welding area, and the thickness of the spacer metal layer is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com