Conductive polymer/ionic polymer/graphene multifunctional film layer coated carbon/sulfur composite positive electrode material and preparation method thereof

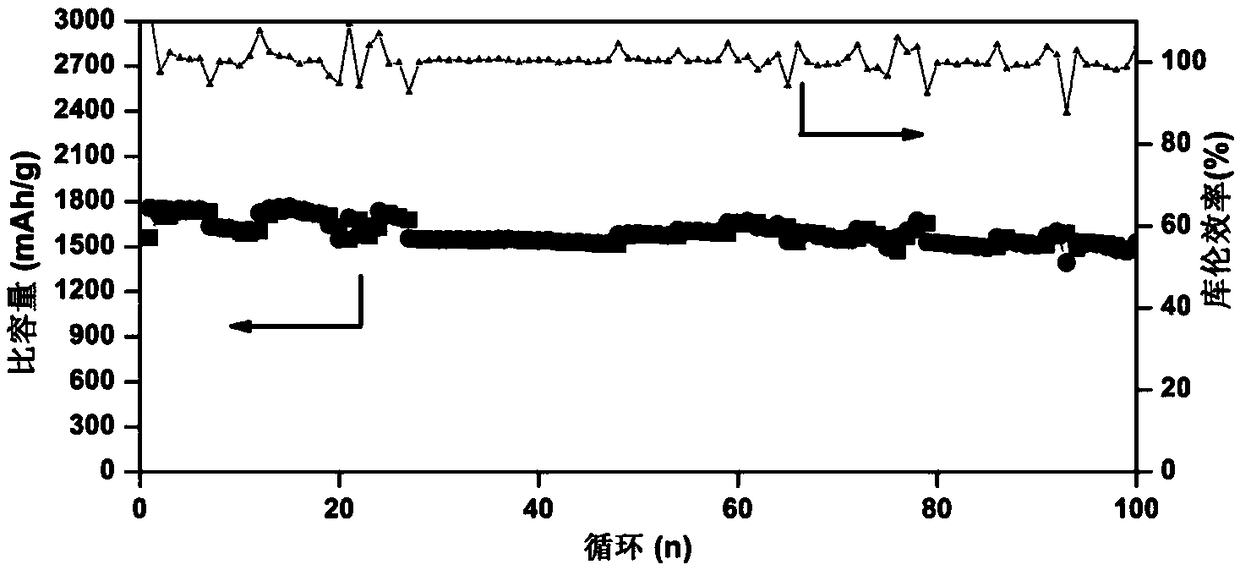

A composite positive electrode material and ionic polymer technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reducing the market competitiveness of lithium-sulfur batteries, affecting the volumetric energy density of batteries, ignoring the requirements of high Coulombic efficiency, etc., to achieve The effect of improving electrode material shedding phenomenon, good deformation resistance and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The first step: the specific surface area after treatment is ≥ 1200cm3 Ketjen black and commercialized sulfur with a purity of 99.5% are mixed according to a weight ratio of 1:9 and put into a closed container filled with an organic solvent carbon disulfide solution, which is dissolved by ultrasonic and vacuum evaporated at low temperature, and the ultrasonic time is 30 minutes , the vacuum degree is 500 Pascals, and the evaporation temperature is 30 degrees. When the organic solution is completely evaporated, a carbon / sulfur compound is obtained;

[0028] The second step: put 1 gram of the obtained carbon / sulfur complex into 200 milliliters of graphene oxide (GO) aqueous solution with a concentration of 0.5 mg / mL for stirring, and add 20 ml of a sodium metabisulfite aqueous solution with a concentration of 50 mg / ml dropwise , the reaction time is 3 minutes, filtered and washed to obtain a redox graphene (RGO)-coated carbon / sulfur composite with a particle size of about ...

Embodiment 2

[0034] The first step: same as embodiment one.

[0035] The second step: put the obtained 1g compound into the graphene oxide aqueous solution containing 200 ml concentration of 1mg / mL for stirring, add dropwise 100ml concentration of 50mg / ml sodium metabisulfite aqueous solution, the reaction time is 2 minutes, Filtration and cleaning to obtain a redox graphene (RGO)-coated carbon / sulfur composite with a particle size of about 8 microns;

[0036] The third step: adding 10 milliliters of 1% dopamine aqueous solution gradually into 200 milliliters of 5 mg / ml graphene-coated carbon / sulfur complex aqueous solution, the reaction time is 20 minutes, and the reaction temperature is 30 degrees , and then obtain polydopamine / graphene (PDA / RGO) coated carbon / sulfur composite after filtering, washing and drying;

[0037] Step 4: Put 1 g of the composite into a low-temperature vapor deposition container, the flow ratio of the polymer monomer aniline (AN) and the oxidant iron oxide is 8:...

Embodiment 3

[0040] The first step: mix the treated Supper P and commercial sulfur (purity 99.5%) according to the weight ratio of 1:8 and put it into a closed container filled with carbon disulfide solution, and after ultrasonic and low-temperature vacuum evaporation treatment, get carbon / sulfur complex. The ultrasonic time is 60 minutes, the vacuum degree is 500 Pascals, and the evaporation temperature is 30 degrees;

[0041] The second step: put the obtained 2g compound into the graphene oxide aqueous solution containing 100 ml concentration of 2mg / mL for stirring, add dropwise 100ml concentration of 60mg / ml sodium metabisulfite aqueous solution, the reaction time is 10 minutes, Filtration and cleaning to obtain a redox graphene (RGO)-coated carbon / sulfur composite with a particle size of about 15 microns;

[0042] The third step: adding 10 milliliters of 0.5% dopamine aqueous solution gradually into 100 milliliters of 1% graphene-coated carbon / sulfur composite aqueous solution, the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com