Process for preparing perovskite structure light-emitting material through temperature inversion method

A technology of perovskite structure and light-emitting material, applied in the direction of light-emitting material, preparation of amino compounds, preparation of organic compounds, etc., can solve the problems of inability to obtain large crystals, slow crystal growth rate, strict temperature control requirements, etc. Mild production conditions, high reproducibility, and energy savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

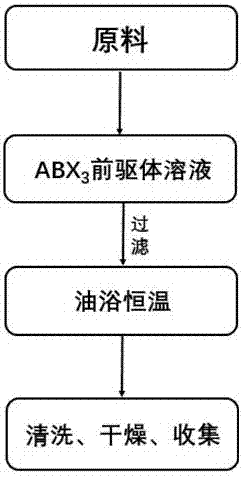

Method used

Image

Examples

Embodiment 1

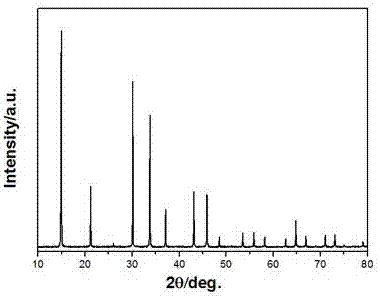

[0030]CH 3 NH 3 PbBr 3 Preparation method of material:

[0031] 1. Configure the precursor solution

[0032] Weigh 0.7833g methyl bromide (CH 3 NH 3 Br), 2.569g lead bromide (PbBr 2 ) into a 50ml beaker with a stirring bar, add 10ml N,N-dimethylformamide (DMF), seal with PM-996 and polytetrafluoroethylene film double-layer film, stir at room temperature with a magnetic stirrer After more than 12 hours, ultrasonic waves can be used to assist dissolution, and the solution is filtered through a PTFE filter membrane with a diameter of 22 μm to obtain a precursor solution.

[0033] 2. Material preparation

[0034] Take the precursor solution in step 1 in four 10ml sample bottles, 2.5ml in each bottle, put the sample bottles containing the precursor solution in an oil bath at 80°C for 3 hours, and a 0.5~10mm particle will be precipitated at the bottom of the container CH 3 NH 3 PbBr 3 .

[0035] 3. CH 3 NH 3 PbBr 3 Washing, drying and collection of materials

[0036]...

Embodiment 2

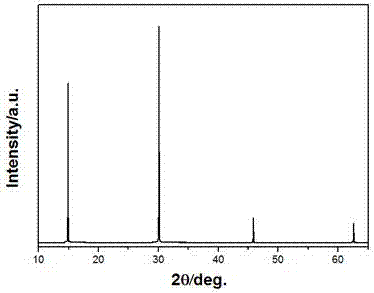

[0038] CH 3 NH 3 PbCl 3 Preparation method of material:

[0039] 1. Configure the precursor solution

[0040] Weigh 0.4722g chloromethylamine (CH 3 NH 3 Cl), 1.9467g lead chloride (PbCl 2 ) into the 50ml beaker P that has been put into the stirring bar, add 10ml dimethyl sulfoxide (DMSO), seal with PM-996 and polytetrafluoroethylene film double-layer film, and stir at room temperature for more than 12 hours with a magnetic stirrer , can be dissolved with the aid of ultrasonic waves, and after the solution is fully dissolved, filter the solution with a PTFE filter membrane with a diameter of 22 μm to obtain a precursor solution.

[0041] 2. Material preparation

[0042] Take the precursor solution in step 1 in four 10ml sample bottles, each bottle is 2.5ml, put the sample bottle containing the precursor solution in an oil bath at 90°C for 3 hours, and 0.5~10mm particles can be precipitated at the bottom of the container CH 3 NH 3 PbCl 3 .

[0043] 3. CH 3 NH 3 PbC...

Embodiment 3

[0046] CH 3 NH 3 PBr 2 Preparation method of material:

[0047] 1. Configure the precursor solution

[0048] Weigh 0.6885g methyl iodide (CH 3 NH 3 I), 1.997g lead iodide (PbI 2 ) in a 50ml beaker with a stirring bar,

[0049] Add 3ml of γ-butyrolactone (GBL) and seal with PM-996 and polytetrafluoroethylene film double-layer film, stir at room temperature with a magnetic stirrer for more than 12 hours, and dissolve with the aid of ultrasonic waves.

[0050] Weigh 0.5222 bromomethylamine (CH 3 NH 3 Br), 1.1726g lead bromide (PbBr 2 ) into a 50ml beaker with a stirring bar, add 7ml of N,N-dimethylformamide (DMF), seal with PM-996 and polytetrafluoroethylene film, and stir at room temperature with a magnetic stirrer For more than 12 hours, it can be dissolved with the aid of ultrasound.

[0051] After the above two solutions are fully dissolved, mix them in a 50ml beaker with a stirring bar, and dissolve them at room temperature for 30 minutes with a magnetic stirrer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com