Magnetic core-shell nanometer composite material with nickel particles and preparation method and application of magnetic core-shell nanometer composite material

A nano-composite material and nickel-loaded technology, applied in the field of nano-materials, can solve the problems of restricting the popularization and application of materials, high prices, and limited precious metal resources, and achieve good use value and application prospects, good morphology and structure, adsorption and catalytic functions excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Fe 3 o 4 @SiO 2 Preparation of @C-Ni Nanomaterials

[0048] a) Fe 3 o 4 Preparation of microspheres: Using solvent hydrothermal method, disperse 3g of nickel chloride hexahydrate and 0.83g of trisodium citrate in 70mL of ethylene glycol, then add 4.8g of sodium acetate, stir in a beaker to form a uniform solution, and then The above homogeneous solution was transferred into a 50mL reactor, and hydrothermally reacted at 200°C for 10 hours. After the reaction was completed, it was cooled to room temperature, and the reactor was taken out, and the reaction solution in the reactor was poured into a beaker, separated under the action of a magnet and washed with water washed several times with ethanol and dried to obtain Fe 3 o 4 Nanospheres, Fe 3 o 4 Microsphere particle size range 110~180nm, Fe 3 o 4 The average particle size of the microspheres is about 150nm.

[0049] b) Core-shell structure nanomaterial Fe 3 o 4 @SiO 2 Preparation: 100mg Fe 3 o 4 The micr...

Embodiment 2

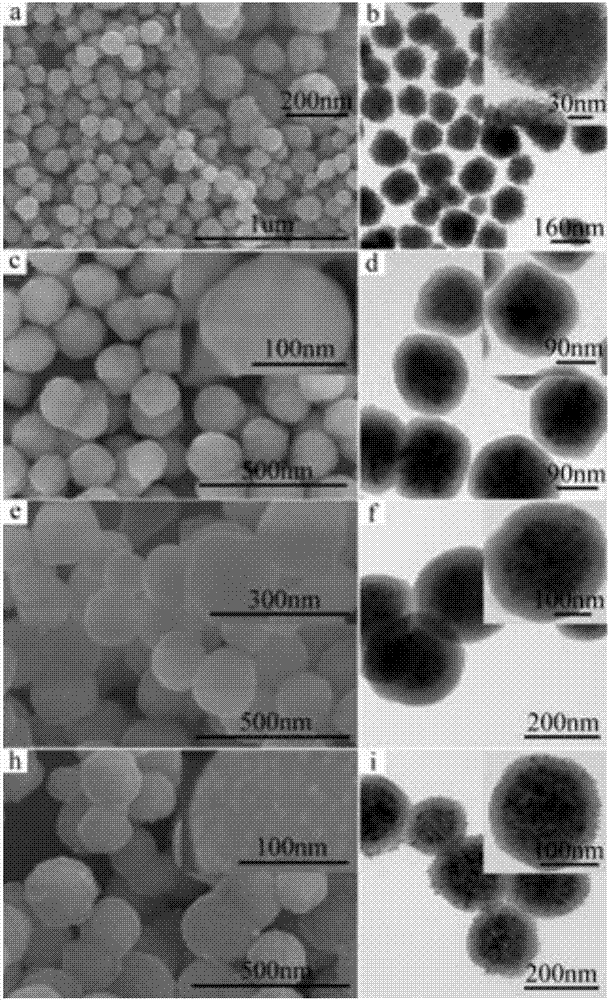

[0057] Effects of Different Thicknesses of Silica Layer on the Size and Density of Nickel Particles

[0058] The difference between the experimental conditions of this example and Example 1 is that the amount of TEOS (orthoethyl silicate) was changed, and the amount of TEOS was adjusted to 93 mg and 0.46 g respectively, to obtain magnetic silicon balls Fe coated with silicon dioxide layers of different thicknesses. 3 o 4 @SiO 2 , and then prepare the core double-shell material Fe loaded with nickel particles of different particle sizes and densities 3 o 4 @SiO 2 @C-Ni. Wherein, when the amount of TEOS is 93mg, 0.28g and 0.46g, the corresponding silicon dioxide layer thicknesses are 7nm, 25nm and 30nm respectively.

[0059] Magnetic silicon sphere Fe coated with silicon dioxide layer of different thickness 3 o 4 @SiO 2 Magnetic core-shell-shell structure nanomaterial Fe prepared as a matrix 3 o 4 @SiO 2 The SEM and TEM images of @C-Ni are as follows figure 2 shown....

Embodiment 3

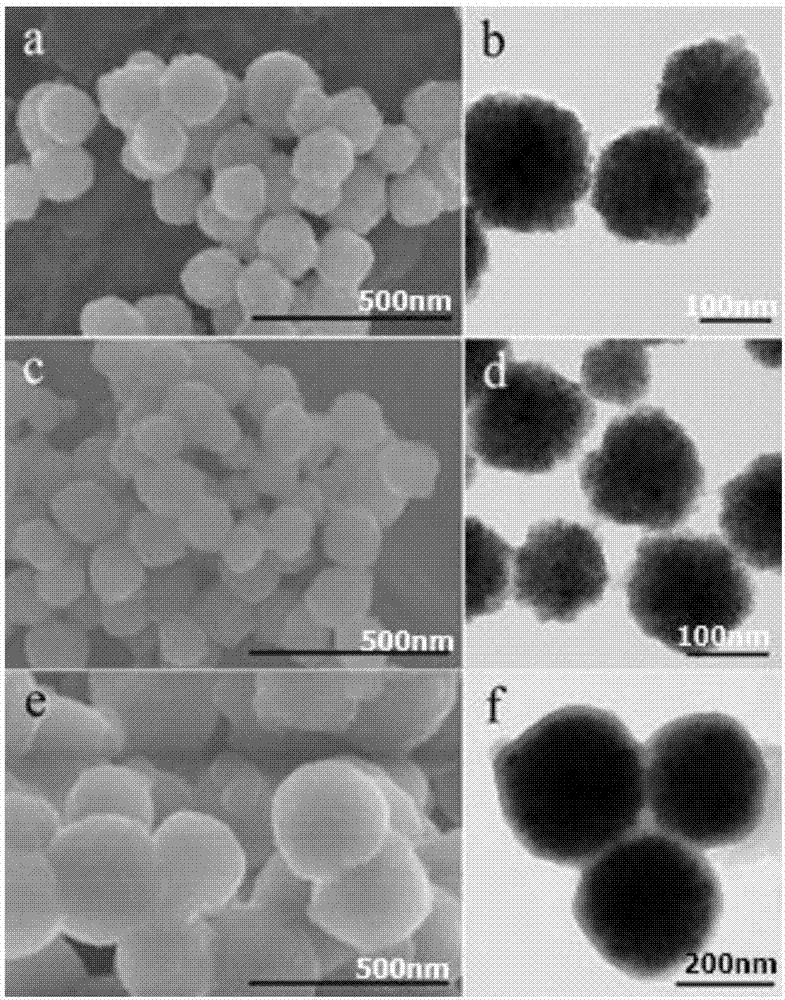

[0064] Fe 3 o 4 Preparation of @C-Ni Nanomaterials

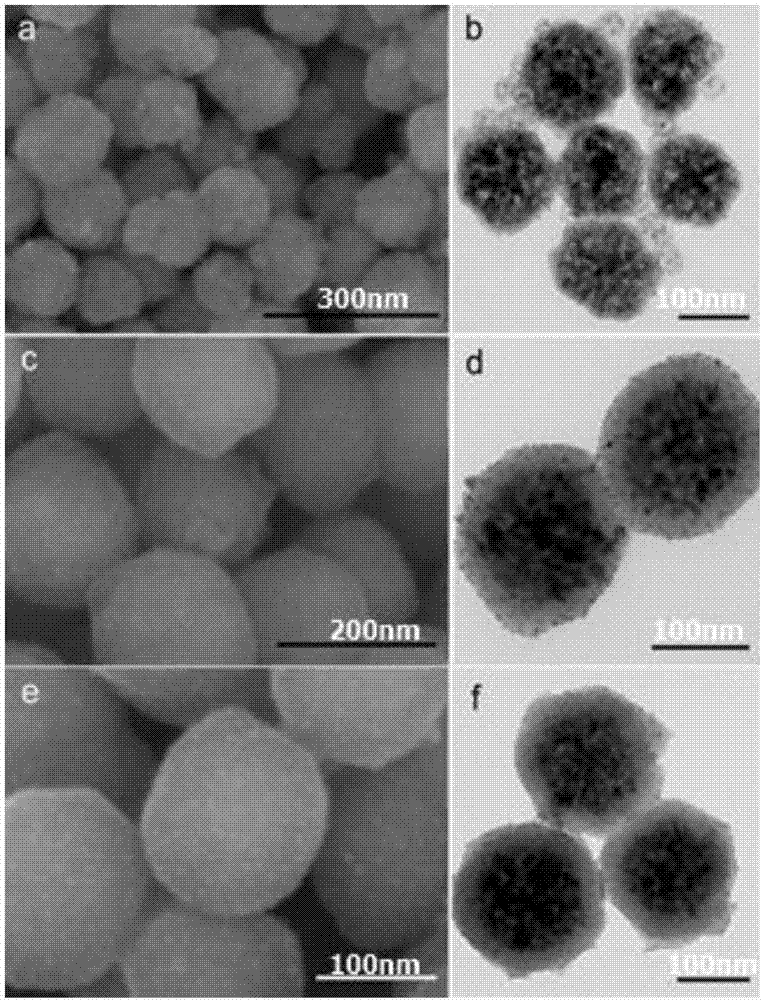

[0065] The difference between this embodiment and embodiment 1 is that directly using Fe 3 o 4 Preparation of core-shell nanomaterial Fe with microspheres as matrix 3 o 4 @RF-Ni 2+ , among them, the amount of resorcinol and nickel nitrate hexahydrate set three investigation groups, respectively, 20mg resorcinol amount and 80mg nickel salt amount; 31mg resorcinol amount and 124mg nickel salt amount; 62mg between The amount of hydroquinone and the amount of 248mg nickel salt; the amount of Fe used in the three investigation groups 3 o 4 The amount of microspheres was all 310 mg.

[0066] Fe coated with nickel salt-doped phenolic resin with different thickness 3 o 4 @RF-Ni 2+ SEM and TEM images of magnetic core-shell nanomaterials image 3 shown. image 3 a, b core-shell nanomaterial Fe 3 o 4 @RF-Ni 2+ The shell thickness is about 7nm; image 3 c, d core-shell nanomaterial Fe 3 o 4 @RF-Ni 2+ The shell thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com