A method for measuring the temperature and emissivity of turbine blades based on three-band radiant light

A turbine blade and radiant light technology, which is applied in the field of radiation temperature measurement, can solve the problems of large emissivity error and inability to eliminate other background radiation sources, and achieves the effect of small calculation amount and improved measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

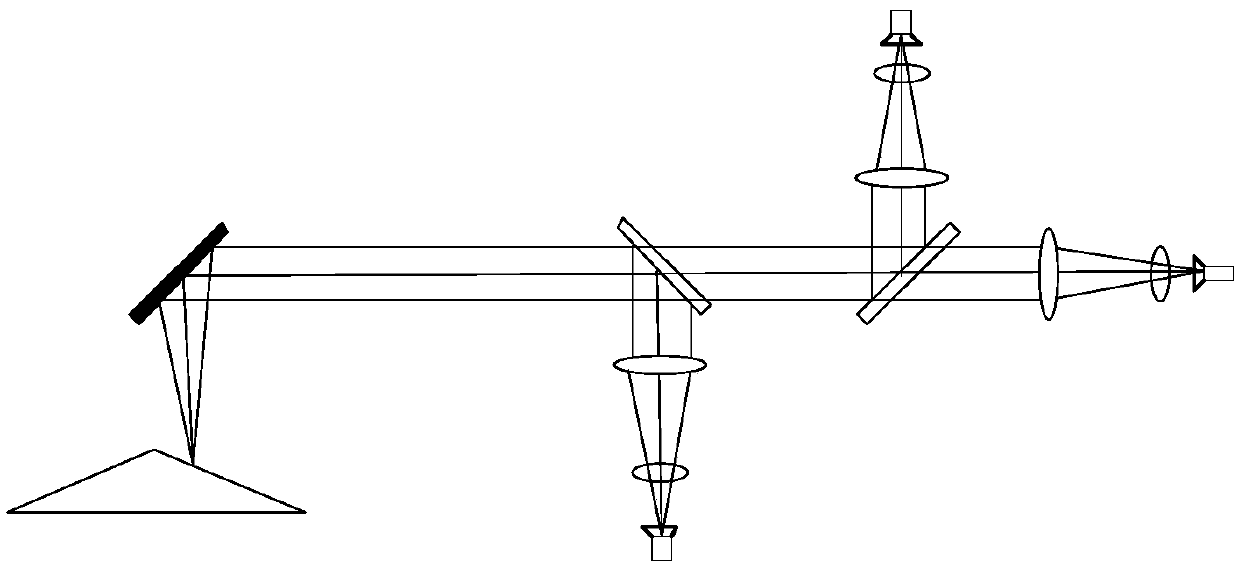

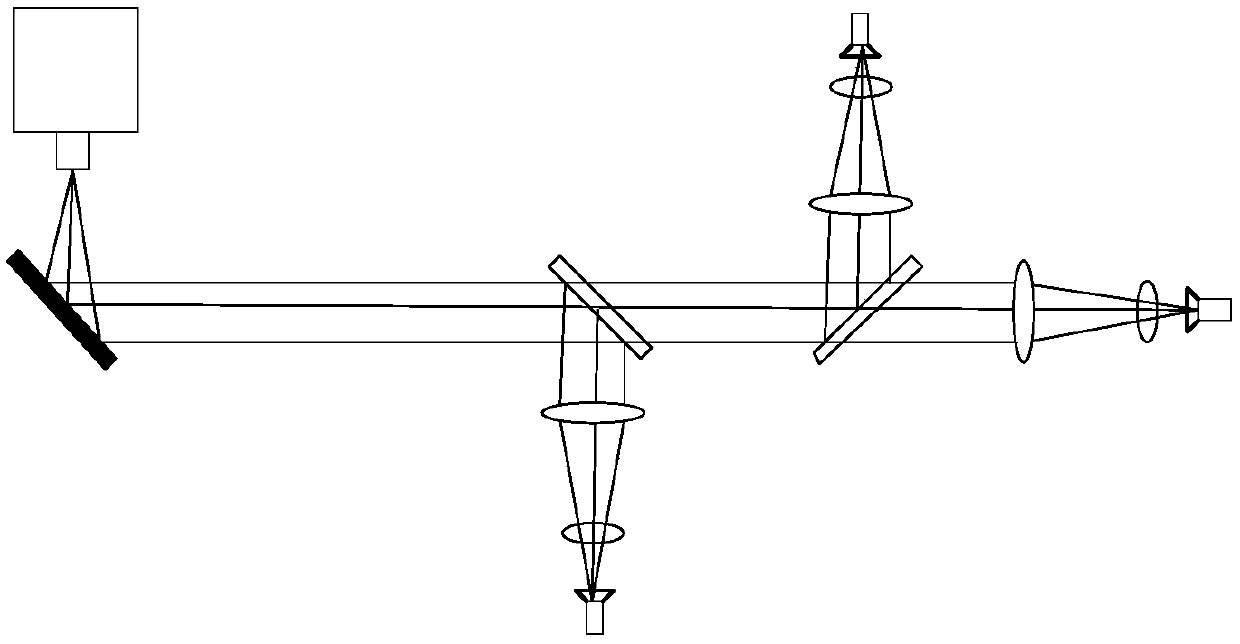

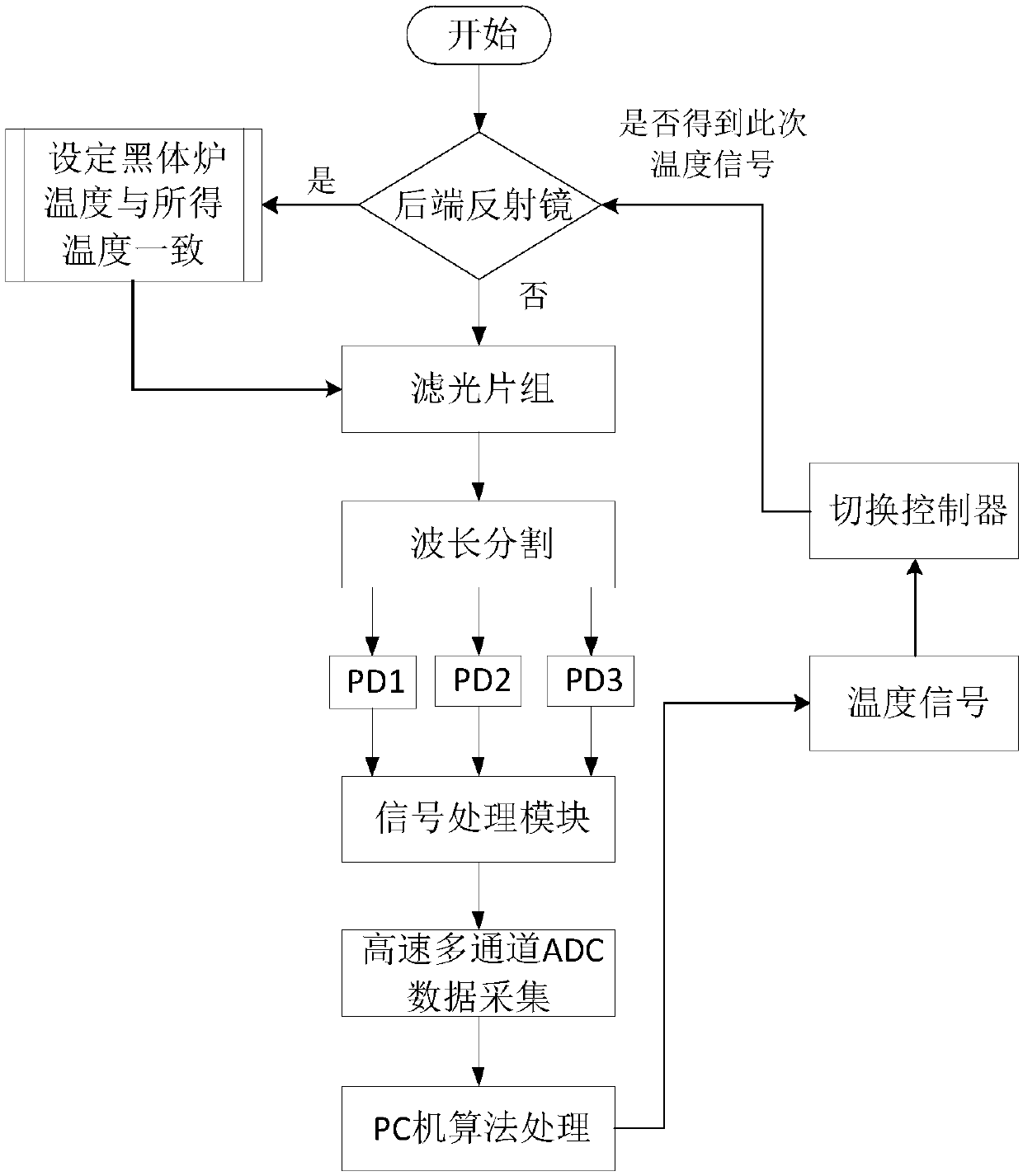

Method used

Image

Examples

Embodiment Construction

[0029] For different spectral wavelengths, the selected three PD detectors have different response bands and different sensitivity. According to the detector material and corresponding response characteristics, silicon detectors are mainly used for those below 1.1um, and indium gallium arsenide detectors are used for those above 1.1um. Detectors have different sensitivity to different wavelength bands. Therefore, for the thermal radiation energy emitted from the surface of the turbine blade, the values measured by different detectors should also be different. If the measured radiant energy values are the same for the temperature results of three different detectors through the algorithm, then it can be reasonably inferred that the influence of the reflected radiation errors of other thermal radiation sources on the system does not lead to erroneous measurement results.

[0030] The present invention is based on the Planck blackbody brightness temperature measurement formula

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com