Dust removing system capable of dynamically and stably adjusting blowing rate

A dust removal system, dynamic and stable technology, used in the removal of smoke and dust, valve details, engine components, etc., can solve problems such as difficulty in precise control, excessive wind speed in branch pipes, and small air volume at the suction point, so as to eliminate unstable air volume and eliminate pressure. Fluctuations, the effect of eliminating resistance dissonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

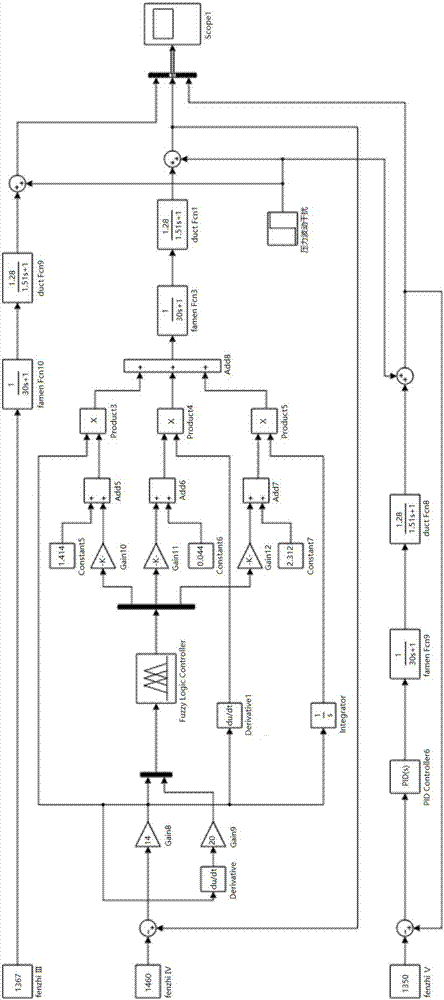

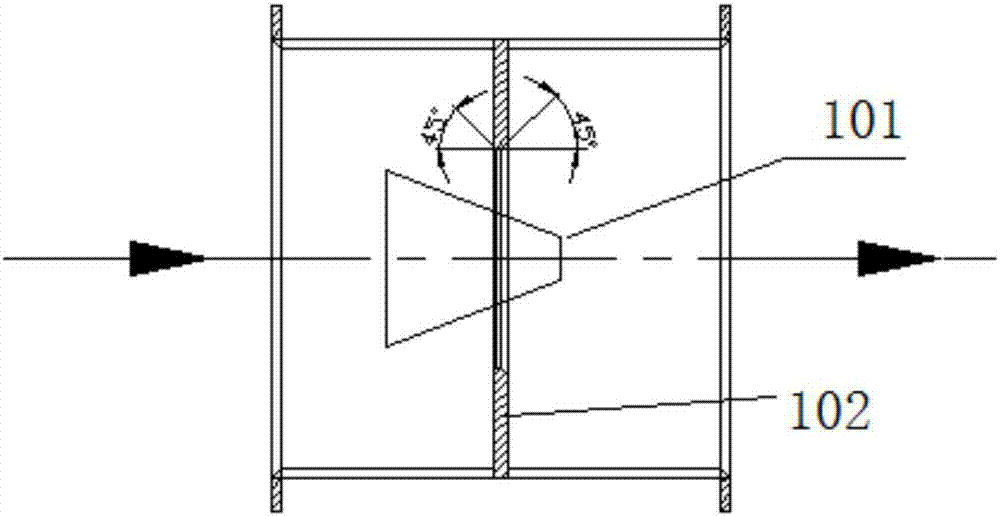

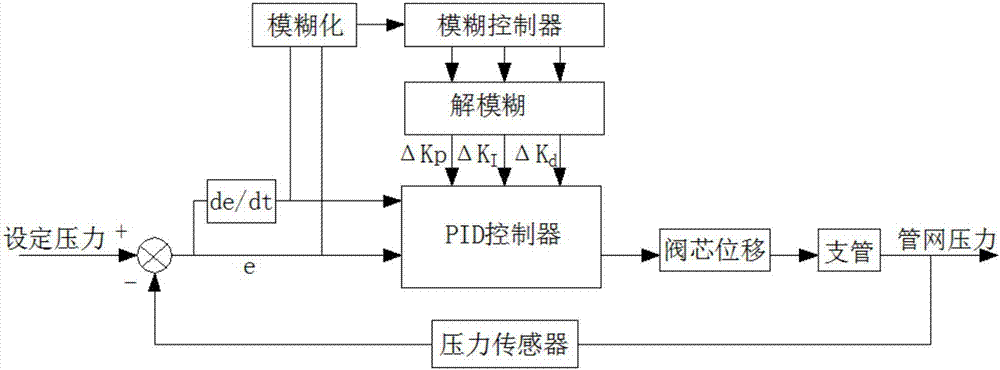

[0028] Below in conjunction with accompanying drawing and embodiment the present invention is further described;

[0029] There are many branch pipes in the dust removal system. When the resistance of a branch pipe changes, the flow rate of the branch pipe will change. At the same time, the change of the branch pipe flow will affect the redistribution of the flow of other branch pipes, causing interference to the flow of other branch pipes, that is, the coupling interference between the branch pipes. The influence of system interference causes the unstable operation of the system. The more serious the coupling interference, the greater the flow change of each branch pipe, and the worse the instability of the system; otherwise, the better the stability of the system. The graph theory analysis shows that the pipe network of the dust removal system is susceptible to large fluctuations due to interference, resulting in unstable operation of the system, and the coupling interference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com