Phosphonitrile compound containing phenolic hydroxyl group, preparation method and application thereof

A technology of phosphazene compound and phenolic hydroxyl group, which is applied in the field of phosphazene compound containing phenolic hydroxyl group and its preparation, and can solve problems such as unfavorable, unsuitable for high multi-layer, high reliability, high adhesion processing performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

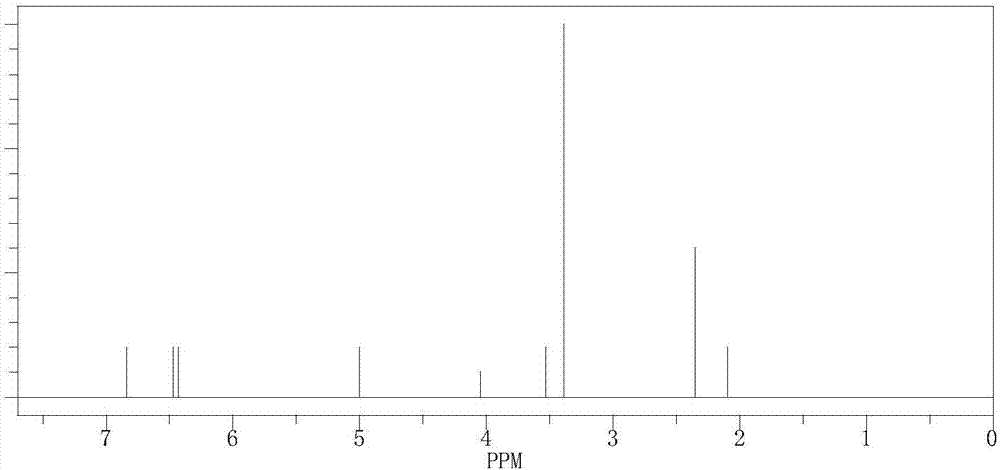

[0094] Put 1mol of hexachlorocyclotriphosphazene, 200mL of acetone, and 5mol of sodium methoxide into a three-port 2000mL glass reactor with a stirring device. While stirring, nitrogen is blown at the same time, the temperature is raised to 60°C, and 20% sodium hydroxide solution is added dropwise over 60 minutes to The pH value is neutral, keep the temperature at 60°C, stir and react for 8 hours, then add 1mol 3-hydroxypropionaldehyde, continue to stir and react for 5h, then cool down to room temperature, keep the pH of the solution at 9, add dropwise for 60min After the reaction, raise the temperature to 60°C, add hydrochloric acid to adjust the pH to 5, and react for 2 hours. After the reaction, use physical methods to remove the inorganic components and water in the system, distill off the solvent in the system, and use methanol precipitation to obtain the phosphazene with the following structure Compound:

[0095]

[0096] Wherein M is a cyclotriphosphazene group, n=2...

Embodiment 2

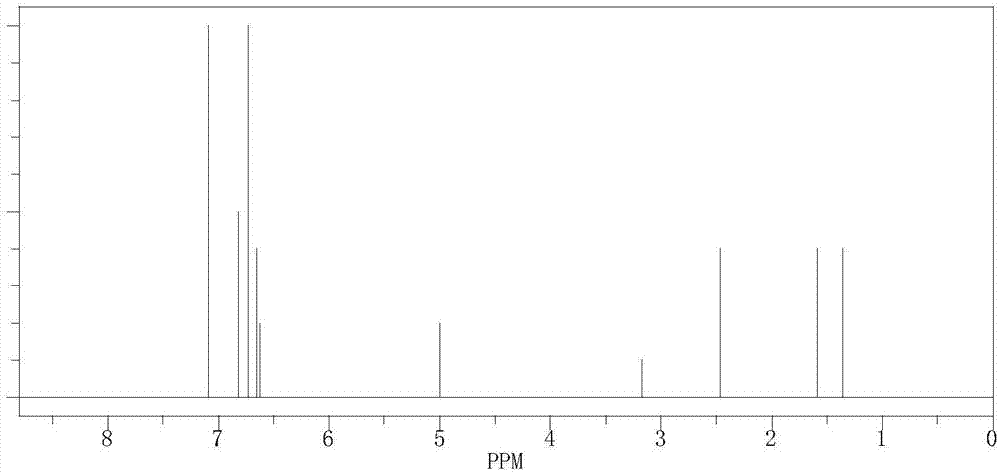

[0098] Put 1mol of hexachlorocyclotriphosphazene, 200mL of acetone, and 5mol of sodium phenoxide into a three-port 2000mL glass reactor with a stirring device. While stirring, nitrogen gas is supplied at the same time, the temperature is raised to 60°C, and 20% sodium hydroxide solution is added dropwise over 60 minutes to The pH value is neutral, keep the temperature at 60°C, stir and react for 6 hours, then add 1mol 4-hydroxycyclohexanone, continue to stir and react for 2h, then cool down to room temperature, keep the pH of the solution at 9, add dropwise for 60min After the reaction, raise the temperature to 60°C, add hydrochloric acid to adjust the pH to 5, and react for 2 hours. After the reaction, use physical methods to remove the inorganic components and water in the system, distill off the solvent in the system, and use methanol precipitation to obtain the phosphazene with the following structure Compound:

[0099]

Embodiment 3

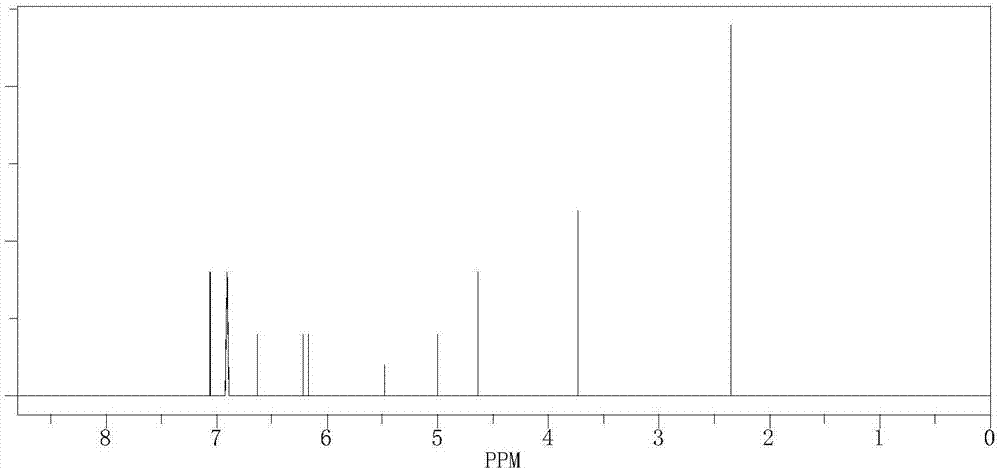

[0101] Put 1 mol of hexachlorocyclotriphosphazene, 200 mL of acetone, and 4 mol of sodium p-methylthiophenate into a three-port 2000 mL glass reactor with a stirring device. While stirring, while blowing nitrogen, the temperature is raised to 60 ° C, and 20% of Sodium hydroxide solution until the pH value is neutral, keep the temperature at 60°C, stir and react for 4 hours, then add 2mol 3,5-dimethyl-4-hydroxybenzaldehyde, continue stirring for 4h, then add 4-hydroxymethyl -3 methoxyphenol 4mol, continue to react for 4h, after the reaction, use physical methods to remove the inorganic components and water in the system, distill off the solvent in the system, and use methanol precipitation to obtain the phosphazene compound with the following structure:

[0102]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| Peel strength between layers | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com