Seedling-period concentrated biogas slurry leaf fertilizer applicable to cotton transplanting and application thereof

A technology of foliar fertilizer and biogas slurry, applied in application, liquid fertilizer, nitrogen fertilizer, etc., can solve the problems of insufficient nutrient absorption, slow seedlings at seedling stage, root damage, etc., and achieve the goals of shortening the time of slowing seedlings, stable properties, and increased yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

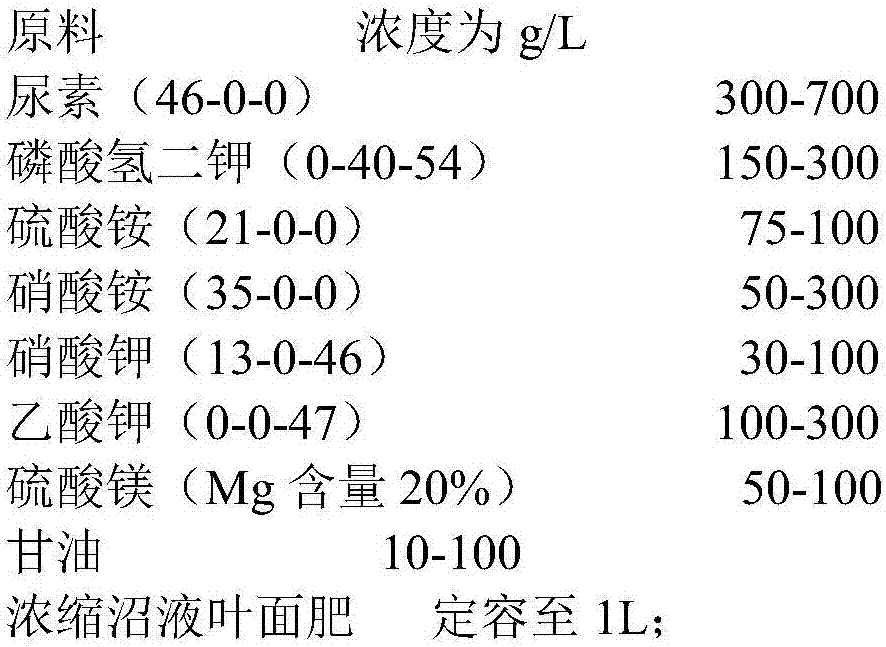

[0047] A seedling concentrated biogas slurry foliar fertilizer suitable for transplanting cotton, which is made of the following concentrations of raw materials:

[0048]

[0049] Based on the above-mentioned raw materials, the effective content of nitrogen, phosphorus and potassium obtained is:

[0050]

[0051]

[0052] A kind of preparation method of seedling concentrated biogas slurry foliar fertilizer suitable for transplanting cotton, its steps are:

[0053] A. Heat the concentrated biogas slurry and control the temperature at 40 or 43 or 45 or 48 or 50°C;

[0054] B. Add the above raw materials into 700mL concentrated biogas slurry in sequence according to a certain proportion of urea, glycerin, ammonium nitrate, potassium nitrate, potassium acetate, dipotassium hydrogen phosphate, ammonium sulfate, and magnesium sulfate, stir evenly, and cool; the temperature is controlled at 20 or 22 or 24 or 25°C;

[0055] C. Then use the concentrated biogas slurry at norm...

Embodiment 2 to Embodiment 13

[0058] A seedling stage concentrated biogas slurry foliar fertilizer suitable for transplanting cotton, which is made of the concentration (g / L) of the following raw materials:

[0059]

[0060] Its preparation steps are identical with embodiment 1.

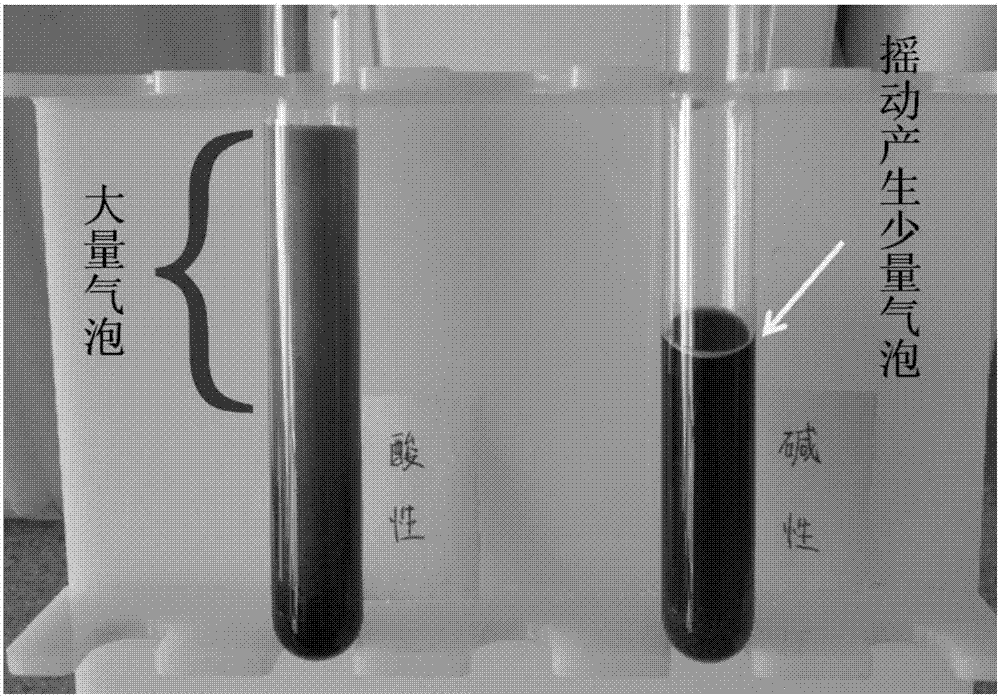

[0061] Since the biogas slurry is rich in natural organic compounds and the solution is weakly alkaline, the raw materials for fertilizer preparation are all neutral (urea, potassium nitrate, etc.) or slightly alkaline (dipotassium hydrogen phosphate, potassium acetate, etc.) raw materials to maintain concentration The original physical and chemical properties of the biogas slurry; the half-price of the hydrated ions of the raw materials used is small, so the solubility is high, the ratio between the types of raw materials and the different forms of the same element is reasonable, and it is not easy to react with metal ions such as calcium, magnesium, zinc, and iron in the liquid fertilizer Nutrients become invalid; the variou...

Embodiment 14

[0063] A kind of application of concentrated biogas slurry foliar fertilizer at seedling stage in transplanting cotton seedlings (transplanting at cotyledon flattening stage): its steps are:

[0064] A. Conducted in a temperature-controlled and dimming greenhouse (20°C or 26 or 30 or 34 or 37 or 40°C), the test was carried out in March 2016;

[0065] B. Taking Jimian 228 as the tested variety, artificial germination in the room, germination and seedling cultivation in sandy soil;

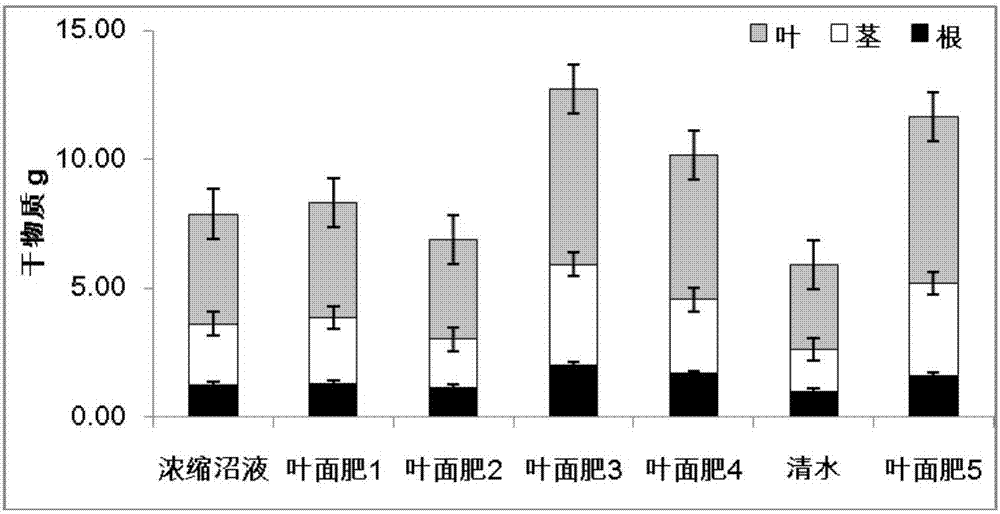

[0066] C. Transplant when the cotyledons are flattened, and carry out the test the next day after transplanting. The test sets clear water and concentrated biogas liquid stock solution (using membrane concentration technology, which is formed by filtering and concentrating the fermented chicken manure mixture step by step, specifically For: a biogas slurry concentrate and engineering preparation method: CN104058799B[P].2014), 3 treatments of concentrated biogas slurry foliar fertilizer (described in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com