Submerged-arc welding tubular welding wire used for idle gear remanufacturing

A tubular welding wire and remanufacturing technology, which is applied in the field of remanufacturing, can solve the problems of idlers without recycling, high maintenance costs, waste of resources, etc., achieve good surfacing welding process performance, improve surface quality, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

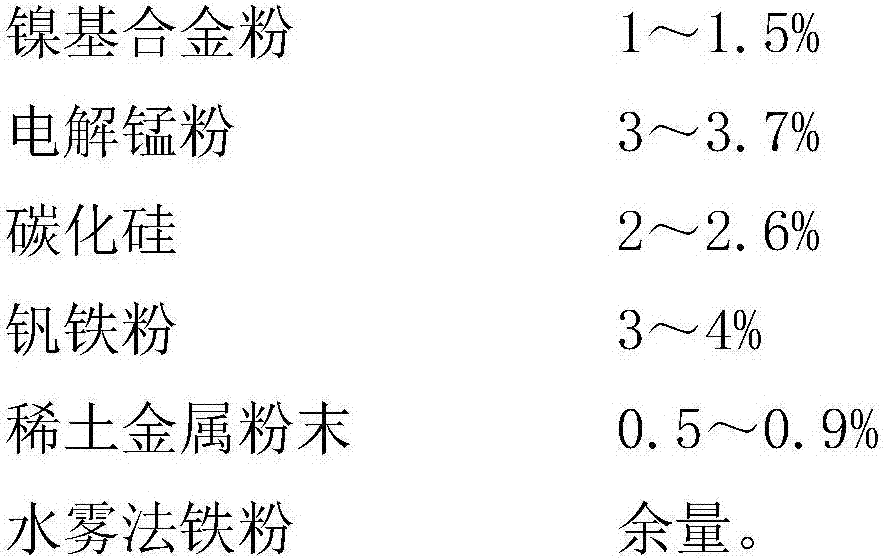

[0014] Submerged arc welding tubular welding wire for idler remanufacturing, including the following components in mass percentage:

[0015]

[0016] The nickel-based alloy powder includes the following components in mass percentage: 16.0% of Cr, 8.0% of Co, 0.8% of Y, 4.0% of Al, 0.2% of C, and the balance of Ni.

[0017] The ferrovanadium powder comprises the following components by mass percentage: Si is 1.5%, Al is 4%, C is 0.1%, P is 0.05%, S is 0.05%, As is 0.1%, Cu is 0.05%, Mn is 0.1%, Ni is 0.2%, V is 70%, and Fe is the balance.

Embodiment 2

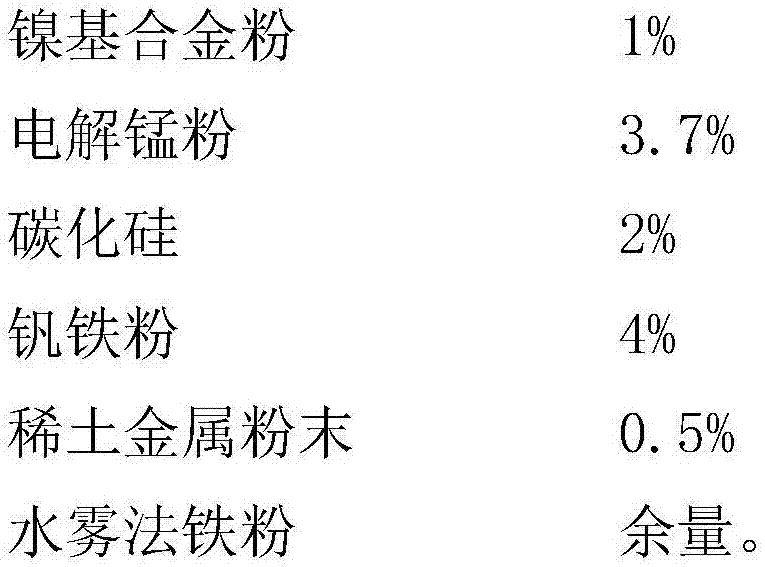

[0019] Submerged arc welding tubular welding wire for idler remanufacturing, including the following components in mass percentage:

[0020]

[0021]

[0022] The nickel-based alloy powder includes the following components in mass percentage: 20.0% of Cr, 5.0% of Co, 0.2% of Y, 6.0% of Al, 0.6% of C, and the balance of Ni.

[0023] The ferrovanadium powder includes the following components in mass percentage: Si is 2%, Al is 2%, C is 0.05%, P is 0.1%, S is 0.1%, As is 0.05%, Cu is 0.1%, Mn is 0.05%, Ni is 0.1%, V is 85%, and Fe is the balance.

Embodiment 3

[0025] Submerged arc welding tubular welding wire for idler remanufacturing, including the following components in mass percentage:

[0026]

[0027] The nickel-based alloy powder includes the following components in mass percentage: 18% of Cr, 7% of Co, 0.6% of Y, 5% of Al, 0.5% of C, and the balance of Ni.

[0028] The ferrovanadium powder comprises the following components by mass percentage: Si is 1.8%, Al is 3%, C is 0.08%, P is 0.09%, S is 0.07%, As is 0.07%, Cu is 0.06%, Mn is 0.08%, Ni is 0.16%, V is 79%, and Fe is the balance.

[0029] Embodiment 1 to Embodiment 3 are welded using the following process:

[0030] The welding wire is surfacing welded on the surface of the workpiece by the welding machine.

[0031] Before surfacing welding, the oil and rust on the surfacing welding part of the workpiece should be removed.

[0032] Further, for larger workpieces lower than medium alloy steel, proper preheating and post-weld stress relief heat treatment must be perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com