Method for removing slag inclusion of continuous casting tundish purging upper nozzle seating brick through argon blowing

A continuous casting tundish and tundish technology, which is applied in the direction of casting molten material containers, casting equipment, manufacturing tools, etc., can solve the problems of affecting the metallurgical effect of removing inclusions, the liquid level of molten steel is prone to fluctuations, and affecting the effect of inclusions, etc. To achieve the effect of highlighting the metallurgical effect, improving the effect, and slowing down the large fluctuation of the molten steel level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

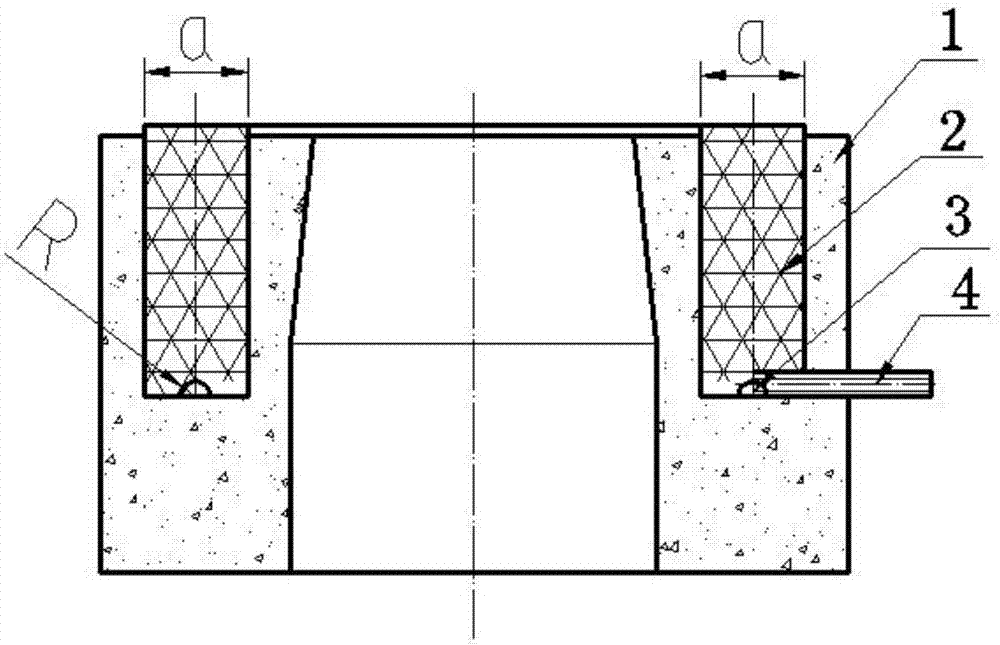

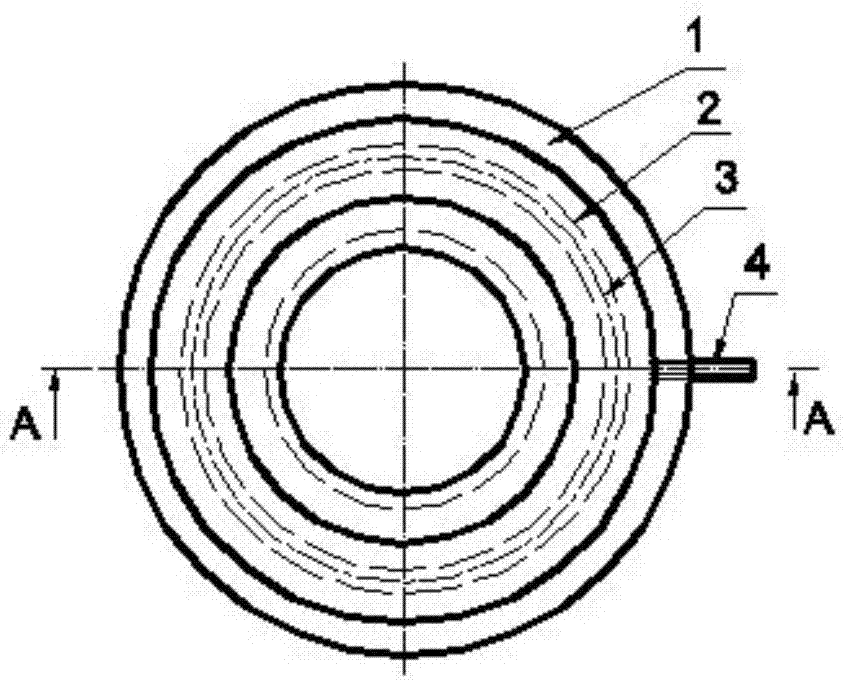

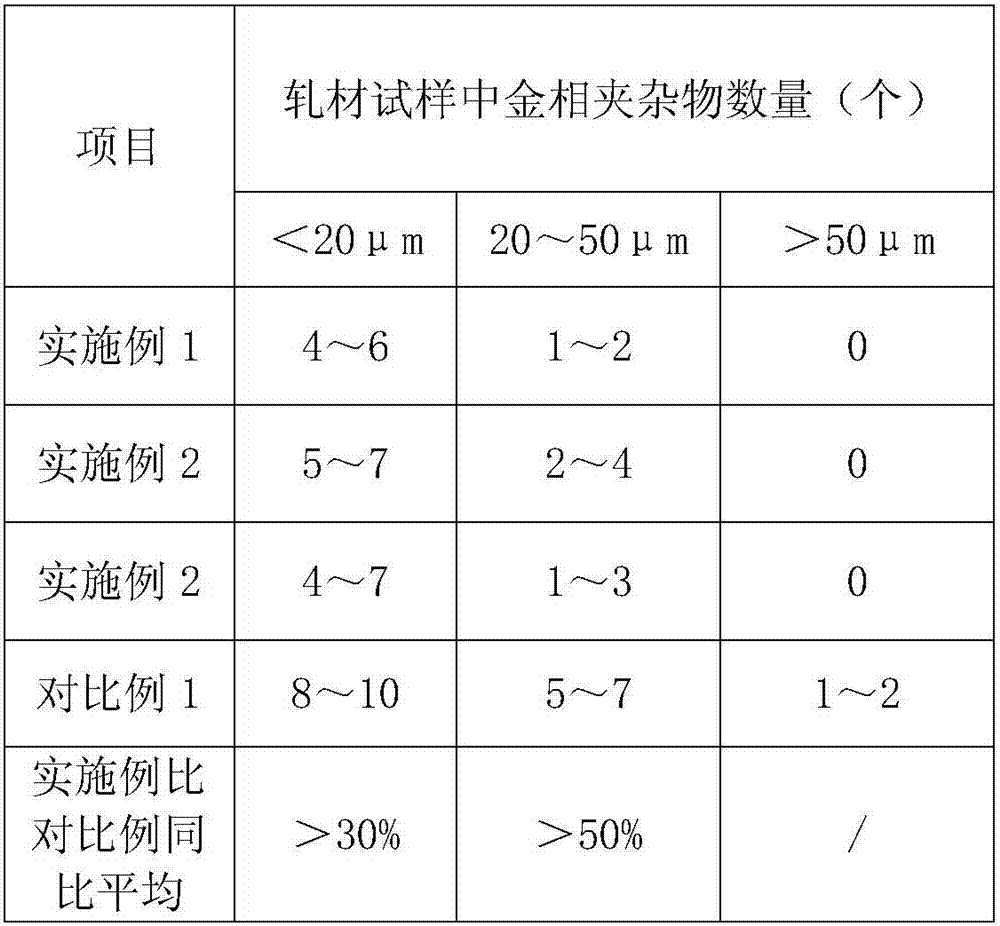

[0026] Such as figure 1 , figure 2 As shown, a method for removing inclusions by blowing argon on the ventilating upper nozzle block of the continuous casting tundish includes the following steps:

[0027] 1) While the continuous casting ladle is being poured, argon gas is blown into the breathable upper nozzle block. The initial argon gas flow rate is 8L / min. When the molten steel in the tundish reaches the normal pouring molten steel level, increase the argon gas flow rate to 12L / min, the flow rate of argon is preferably controlled by the slight fluctuation of the molten steel level in the area directly above the vent block;

[0028] 2) The first furnace is poured in the tundish. After the molten steel surface in the tundish has overflowed the ladle nozzle, add 50kg of high-alkalinity and low-carbon tundish covering agent from the molten steel injection area in the tundish, and place it directly above the block of the ventilated upper nozzle. Add 20kg of high-alkalinity a...

Embodiment 2

[0038] The method for removing inclusions by blowing argon to the breathable upper nozzle block of the continuous casting tundish as described in Example 1, the difference lies in:

[0039] A method for removing inclusions by blowing argon on a ventilating upper nozzle block of a continuous casting tundish, comprising the following steps:

[0040] 1) While the continuous casting ladle is being poured, argon gas is blown into the breathable upper nozzle block. The initial argon gas flow rate is 12L / min. When the molten steel in the tundish reaches the normal pouring molten steel level, increase the argon gas flow rate to 16L / min, the flow rate of argon is preferably controlled by the slight fluctuation of the molten steel level in the area directly above the vent block;

[0041] 2) The first furnace is poured in the tundish. After the liquid steel surface in the tundish overflows the nozzle of the ladle, add 30kg of high-alkalinity and low-carbon tundish covering agent from the...

Embodiment 3

[0047] The method for removing inclusions by blowing argon to the breathable upper nozzle block of the continuous casting tundish as described in Example 1, the difference lies in:

[0048] A method for removing inclusions by blowing argon on a ventilating upper nozzle block of a continuous casting tundish, comprising the following steps:

[0049] 1) While the continuous casting ladle is being poured, argon gas is blown into the breathable upper nozzle block. The initial argon gas flow rate is 10NL / min. When the molten steel in the tundish reaches the normal pouring molten steel level, increase the argon gas flow rate to 14NL / min, the flow rate of argon is preferably controlled by the slight fluctuation of the molten steel level in the area directly above the vent block;

[0050] 2) The first furnace is poured in the tundish. After the liquid steel surface in the tundish overflows the nozzle of the ladle, add 80kg of high-alkalinity and low-carbon tundish covering agent from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com