In-situ construction method and application of super-hydrophobic surface adopting micro/nano hierarchical structure

A technology of superhydrophobic surface and hierarchical structure, which can be used in devices for coating liquids on surfaces, special surfaces, pretreated surfaces, etc. It can solve the problems of low bonding strength, high production cost, and limit superhydrophobic materials, and achieve low cost. , the effect of short process cycle and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

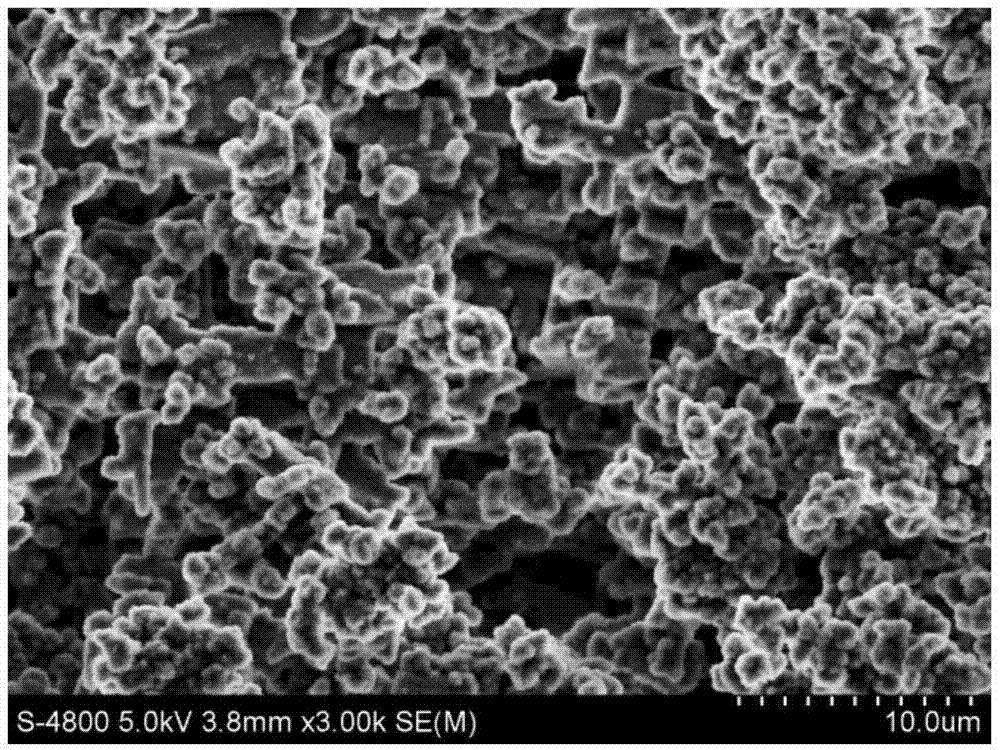

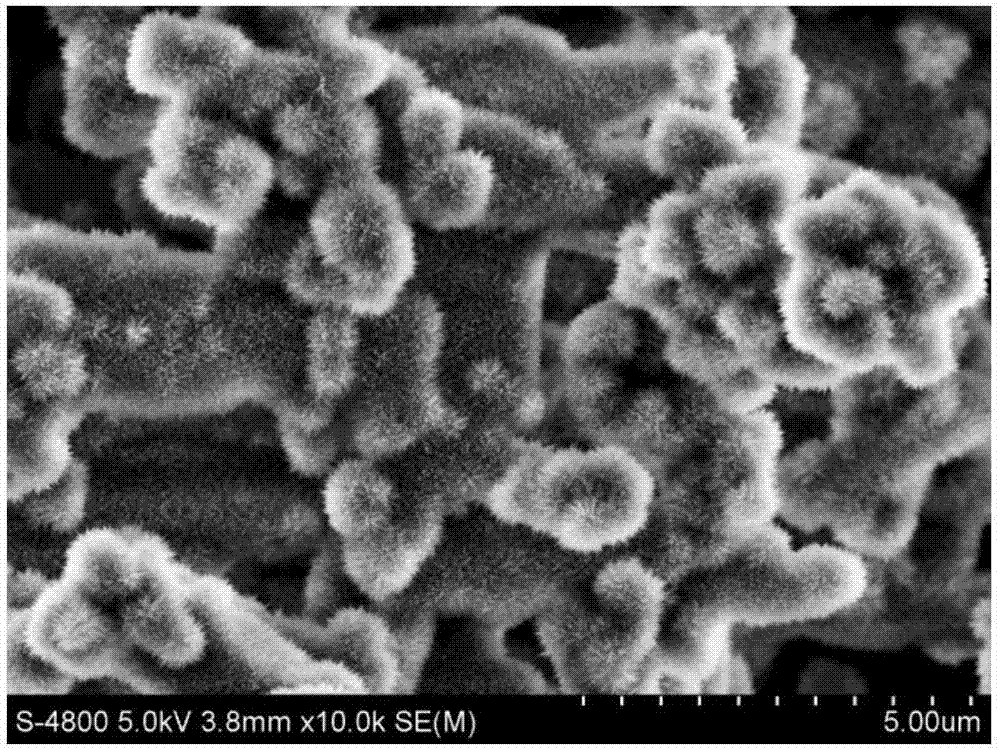

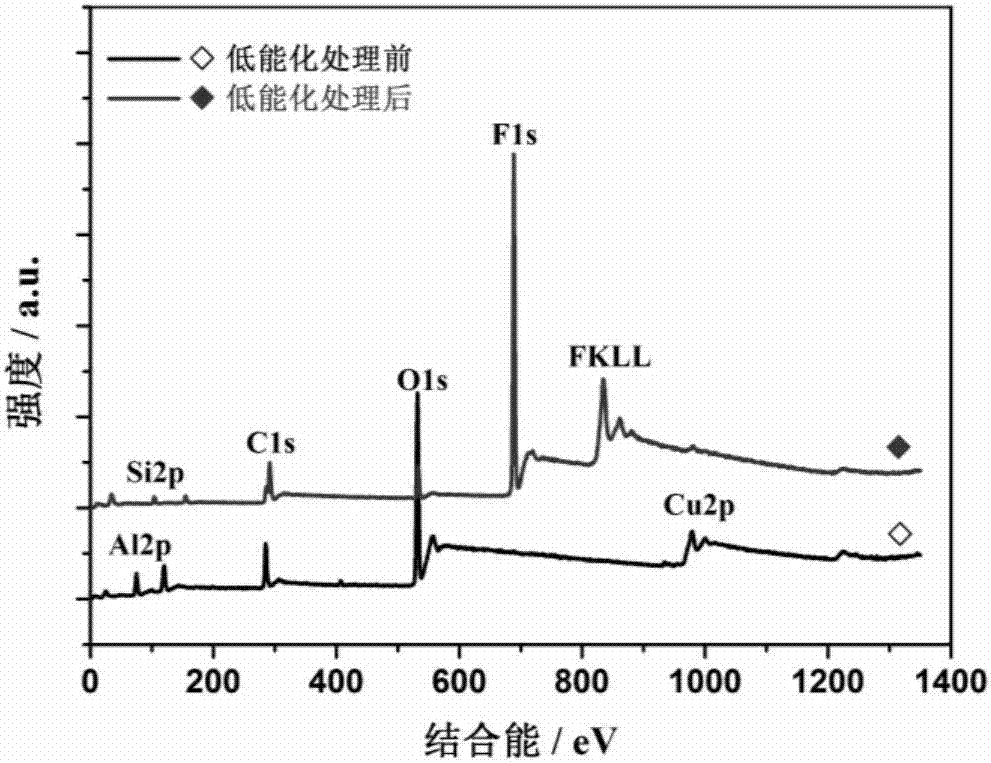

[0029] The preparation method of the superhydrophobic surface with micro-nano hierarchical structure of the present invention is as follows:

[0030] The first step is to use pure aluminum (99.6%) as the base material, and use wire cutting to process the base material into a size of 1mm×15mm×15mm, and use No. 1 to No. 6 metallographic sandpaper to polish the surface of the base material until there is no scratch under the naked eye and then ultrasonically cleaned in acetone, absolute ethanol and distilled water for 10 minutes, and dried for later use;

[0031] In the second step, using the electrochemical etching method, using the aluminum sheet as the anode and the platinum sheet as the cathode, the concentration of the NaCl electrolyte is 0.1mol / L, the voltage is 8V, and the etching time is 2.5h, to obtain micron-sized particles on the surface of the substrate. structure.

[0032] The 3rd step, utilize hydrothermal method, take reactor as reaction container, by placing the ...

Embodiment 2

[0036] The preparation method of the superhydrophobic surface with micro-nano hierarchical structure of the present invention is as follows:

[0037] The first step is to use pure aluminum (99.6%) as the base material, and use wire cutting to process the base material into a size of 1mm×15mm×15mm, and use No. 1 to No. 6 metallographic sandpaper to polish the surface of the base material until there is no scratch under the naked eye and then ultrasonically cleaned in acetone, absolute ethanol and distilled water for 10 minutes, and dried for later use;

[0038] In the second step, using the electrochemical etching method, using the aluminum sheet as the anode and the platinum sheet as the cathode, the concentration of the NaCl electrolyte is 0.08mol / L, the voltage is 6V, and the etching time is 2.5h, to obtain micron-sized particles on the surface of the substrate. structure.

[0039] The third step utilizes the hydrothermal method, with the reactor as the reaction vessel, by ...

Embodiment 3

[0043]The preparation method of the superhydrophobic surface with micro-nano hierarchical structure of the present invention is as follows:

[0044] The first step is to use pure aluminum (99.6%) as the base material, and use wire cutting to process the base material into a size of 1mm×15mm×15mm, and use No. 1 to No. 6 metallographic sandpaper to polish the surface of the base material until there is no scratch under the naked eye and then ultrasonically cleaned in acetone, absolute ethanol and distilled water for 10 minutes, and dried for later use;

[0045] In the second step, using the electrochemical etching method, using the aluminum sheet as the anode and the platinum sheet as the cathode, the NaCl electrolyte concentration is 0.12mol / L, the voltage is 4V, and the etching time is 1.5h, to obtain micron-sized particles on the surface of the substrate. structure.

[0046] The third step utilizes the hydrothermal method, with the reactor as the reaction vessel, by placing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com