Viscous battery separator and lithium ion battery employing same

A battery separator and viscous technology, applied in the direction of separators/films/diaphragms/spacers, secondary batteries, battery pack components, etc., can solve the problems of poor safety performance, low battery flatness and hardness, and improve the The effect of flatness and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of positive electrode sheet:

[0039] Lithium cobaltate, conductive agent superconducting carbon (Super-P), and binder polyvinylidene fluoride (PVDF) are uniformly mixed at a mass ratio of 97:1.5:1.5 to form a positive slurry for lithium-ion batteries with a certain viscosity. The slurry is coated on the current collector aluminum foil, dried at 85°C and then cold pressed; then trimmed, cut, and slit. After slitting, it is dried at 110°C under vacuum for 4 hours, and the tabs are welded. The positive plate of lithium ion battery is made.

[0040] Preparation of negative electrode sheet:

[0041] The graphite and the conductive agent Super-P (Super-P), the thickener sodium carboxymethyl cellulose (CMC), and the binder styrene butadiene rubber (SBR) are made into a slurry at a mass ratio of 96:2.0:1.0:1.0 , Coated on the current collector copper foil and dried at 85 ℃, trimming, cutting, slitting, after slitting, drying at 110 ℃ under vacuum conditions for 4 hours,...

Embodiment 2

[0049] The difference from Example 1 is the preparation of the diaphragm:

[0050] 1) Take a polypropylene microporous membrane with a thickness of 16μm as the base membrane;

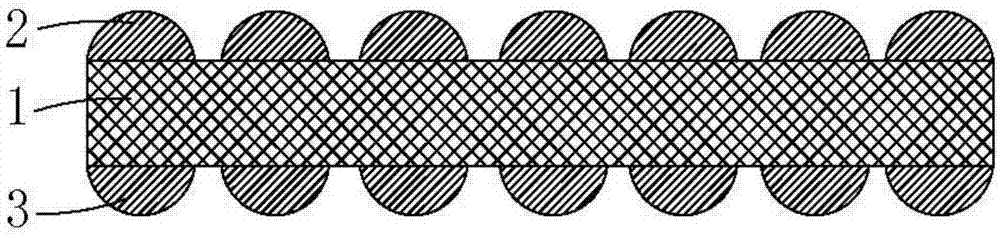

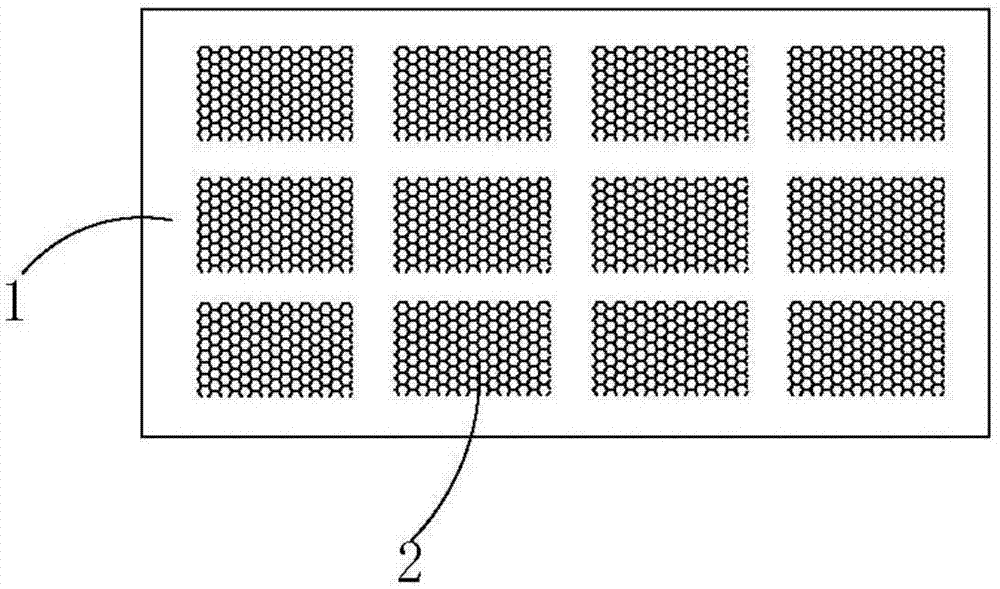

[0051] 2) Mix ethylene-tetrafluoroethylene copolymer, sodium carboxymethyl cellulose and polyacrylate in deionized water at a mass ratio of 92:1.0:7.0 to form an aqueous fluoropolymer coating slurry with a solid content of 15% The fluorine-containing polymer coating slurry is coated on one surface of the base film by screen printing. After drying, a fluorine-containing polymer coating uniformly distributed in an island shape is obtained. The coating thickness is 2μm, the coating area is 90% of the base film area;

[0052] 3) Mix acrylic-styrene copolymer, sodium carboxymethyl cellulose and polyacrylate in deionized water at a mass ratio of 92:1.0:7.0 to form an aqueous acrylic polymer coating slurry with a solid content of 15%. And by screen printing, the acrylic polymer coating slurry is coated on the other...

Embodiment 3

[0055] The difference from Example 1 is the preparation of the diaphragm:

[0056] 1) Take a polyimide film with a thickness of 16 μm as the base film;

[0057] 2) Mix the polyvinylidene fluoride-hexafluoropropylene copolymer, sodium carboxymethyl cellulose and polyacrylate in deionized water at a mass ratio of 89:1.5:9.5 to form an aqueous fluoropolymer with a solid content of 10% Coating slurry, the fluoropolymer coating slurry is coated on one surface of the base film by extrusion coating, and then dried to obtain a uniformly distributed fluoropolymer coating in island shape. The coating thickness is 1μm, and the coating area is 75% of the base film area;

[0058] 3) Mix acrylic acid-silicone copolymer, sodium carboxymethyl cellulose and polyacrylate in deionized water at a mass ratio of 89:1.5:9.5 to form an aqueous acrylic polymer coating slurry with a solid content of 10%. And by extrusion coating, the acrylic polymer coating slurry is coated on the other surface of the base ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com