Special runner pipe for casting and preparation method thereof

A sprue tube, a special technology, applied in casting molding equipment, applications, casting molds, etc., can solve the problems that are not suitable for high-end casting, pottery tubes are not suitable for high-end casting, and the refractoriness is not high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing a special sprue pipe for casting, comprising the following steps:

[0037] 1. The bauxite raw material and the bonded clay green crucible are respectively crushed to pass through a 100-mesh sieve;

[0038] 2. Heat the crushed bauxite raw meal to 900-1100°C and keep it warm for 4-5 hours to prepare bauxite light burnt material;

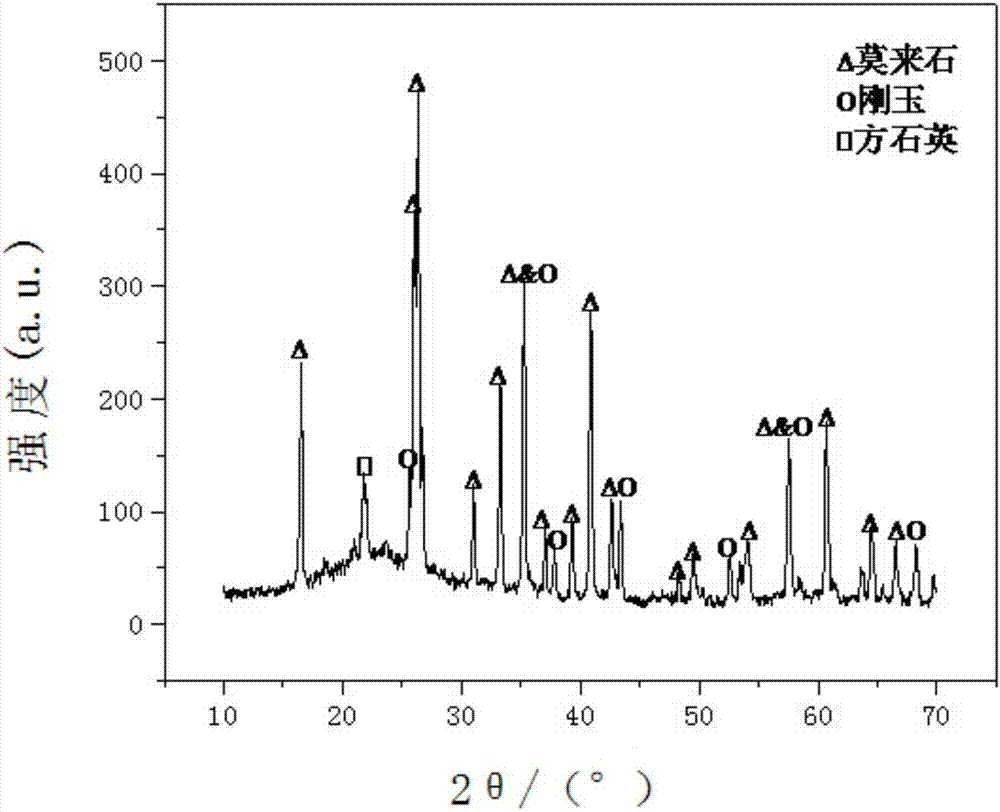

[0039] 3. According to Al in the target product 2 o 3 The mass percentage is 56-60%, SiO 2 The formula is designed with a mass percentage of 30-34%, and the bauxite light burnt material and green crucible clay are respectively weighed and mixed to obtain a mixture;

[0040] 4. Carry out dry co-grinding of the mixture with a Raymond mill, pass the co-grinding material through a 200-mesh sieve and electromagnetically remove iron to obtain the batch material;

[0041] 5. Use the obtained batch materials to rough mud for 1 or 2 times with a mud refining machine. The mud is stale for at least one week after rough refining;...

Embodiment 1

[0049] 1. The bauxite raw material and the bonded clay green crucible are respectively crushed to pass through a 100-mesh sieve;

[0050] 2. Heat the crushed bauxite raw meal to 1000°C and keep it warm for 4 hours to prepare bauxite light burnt material;

[0051] 3. According to Al in the target product 2 o 3 56.8% by mass, SiO 2 The mass percentage is 32% ratio design formula, and take by weighing bauxite light burnt material and green crucible clay respectively, mix and obtain mixture;

[0052] 4. Carry out dry co-grinding of the mixture with a Raymond mill, pass the co-grinding material through a 200-mesh sieve and electromagnetically remove iron to obtain the batch material;

[0053] 5. Use the obtained batch materials to rough mud for 2 times with a mud refining machine. After rough refining, the mud is stale for a week;

[0054] 6. Refining the stale mud with a vacuum mud refining machine, and then extruding it with a pipe extruder to shape it. For thick-walled tub...

Embodiment 2

[0061] 1. The bauxite raw material and the bonded clay green crucible are respectively crushed to pass through a 100-mesh sieve;

[0062] 2. Heat the crushed bauxite raw meal to 900°C and keep it warm for 5 hours to prepare bauxite light burnt material;

[0063] 3. According to Al in the target product 2 o 3 56% by mass, SiO 2 The mass percentage is 34% ratio design formula, and take by weighing bauxite light burnt material and green crucible clay respectively, mix and obtain mixture;

[0064] 4. Carry out dry co-grinding of the mixture with a Raymond mill, pass the co-grinding material through a 200-mesh sieve and electromagnetically remove iron to obtain the batch material;

[0065] 5. Use the obtained batch materials to rough mud for 2 times with a mud refining machine. After rough refining, the mud is old for 10 days;

[0066] 6. Refining the stale mud with a vacuum mud refining machine, and then extruding it with a pipe extruder to shape it. For thick-walled tubes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com