Method for reducing underground water pollution of in-situ uranium leaching ore-bearing and water-bearing stratum

A technology for groundwater pollution and in-situ leaching of uranium, which is applied in the treatment of contaminated groundwater/leachate, water/sewage treatment, chemical instruments and methods, etc. It can solve the problems of secondary pollution, waste of resources, and long treatment period , to reduce the processing cost and achieve the effect of comprehensive recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

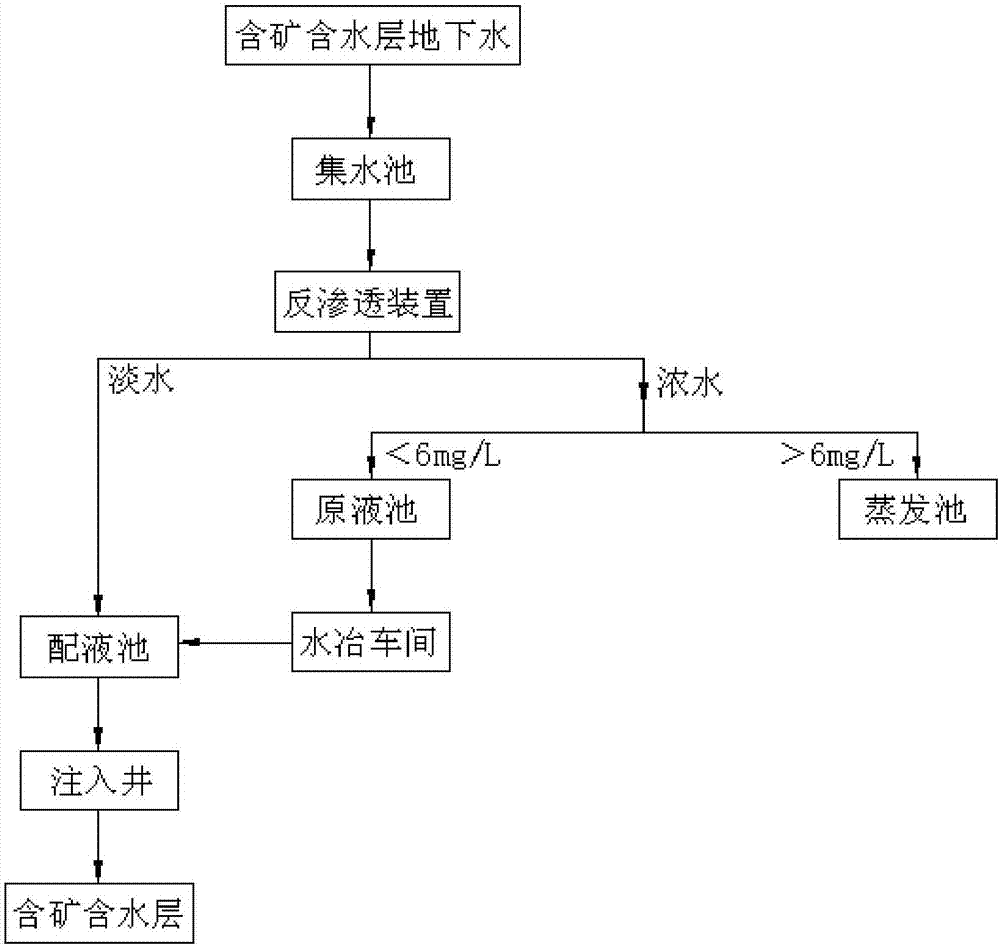

[0026] Taking a uranium mine as an example, such as figure 1 Shown, adopt a kind of method of the present invention to reduce the groundwater pollution of uranium mining ore-bearing aquifer by in-situ leaching, it comprises the steps:

[0027] (a) When the uranium mine field mining area is shut down or decommissioned, and the average uranium concentration of the leachate in the mining area is less than or equal to 3mg / L, the groundwater in the ore-bearing aquifer is treated from step (b) to step (e).

[0028] (b) Raising groundwater from mineral-bearing aquifers to surface sumps through pumping wells.

[0029] (c) Mineral-bearing aquifer groundwater in the sump enters the reverse osmosis unit.

[0030] (d) Concentrated water produced by the reverse osmosis device, when the concentration of uranium is greater than or equal to 6mg / L, the concentrated water is discharged to the stock solution pool, as the stock solution for reuse, it enters the water metallurgy workshop to extra...

Embodiment 2

[0035] Taking a uranium mine as an example, such as figure 1 Shown, adopt a kind of method of the present invention to reduce the groundwater pollution of uranium mining ore-bearing aquifer by in-situ leaching, it comprises the steps:

[0036] (a) When the mining area of the uranium mine is shut down or decommissioned, and the leaching rate of the mining area is greater than or equal to 75%, the groundwater in the ore-bearing aquifer is treated from step (b) to step (e).

[0037] (b) Raising groundwater from mineral-bearing aquifers to surface sumps through pumping wells.

[0038] (c) Mineral-bearing aquifer groundwater in the sump enters the reverse osmosis unit.

[0039] (d) Concentrated water produced by the reverse osmosis device, when the concentration of uranium is greater than or equal to 6mg / L, the concentrated water is discharged to the stock solution pool, as the stock solution for reuse, it enters the water metallurgy workshop to extract uranium, and the waste li...

Embodiment 3

[0044] Taking a uranium mine as an example, such as figure 1 Shown, adopt a kind of method of the present invention to reduce the groundwater pollution of uranium mining ore-bearing aquifer by in-situ leaching, it comprises the steps:

[0045] (a) When the uranium mine field mining area is shut down or decommissioned, and the average uranium concentration of the leachate in the mining area is less than or equal to 3mg / L, the groundwater in the ore-bearing aquifer is treated from step (b) to step (e).

[0046] (b) Raising groundwater from mineral-bearing aquifers to surface sumps through pumping wells.

[0047] (c) Mineral-bearing aquifer groundwater in the sump enters the reverse osmosis unit.

[0048](d) Concentrated water produced by the reverse osmosis device, when the concentration of uranium is greater than or equal to 6mg / L, the concentrated water is discharged to the stock solution pool, as the stock solution for reuse, it enters the water metallurgy workshop to extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com