Superconducting and super corrosion resistant functional coating for fuel cell metal bipolar plate and preparation method thereof

A metal bipolar plate, fuel cell technology, applied in metal material coating process, battery electrode, coating and other directions, can solve the problems of inability to meet civilian promotion, rapid increase in surface resistance, and failure to meet the standards for battery use, etc. Achieve the effects of low corrosion current density, low contact resistance, and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

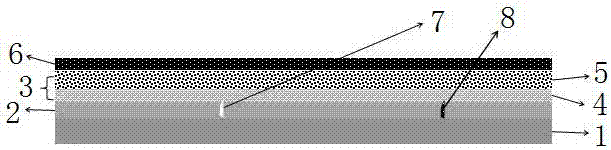

[0030] A preparation method for claiming a fuel cell metal bipolar plate superconducting supercorrosion-resistant functional coating, the self-healing layer 2 of the coating material, the supercorrosion-resistant layer 3 and the superconducting layer 6 that can be deposited selectively are The one-time deposition is completed in the magnetic filter arc ion plating equipment equipped with a hot wire assisted ion source. The targets of the coating equipment are distributed on both sides of the vacuum furnace body, and there are at least 3 target assembly positions on the same horizontal plane, one of which is Install titanium alloy doped target or tungsten alloy doped target, and install tungsten alloy doped target or titanium alloy doped target and graphite target on the other side, including the following process steps:

[0031] Step 1: Pre-treatment of the workpiece: put the workpiece into the ultrasonic cleaning equipment for ultrasonic degreasing cleaning, pure water ultraso...

Embodiment 1

[0038] The alloy components that make up the super corrosion-resistant layer are alloy nitrides and oxides containing 5wt% tungsten, and other additives can be one or more of titanium, vanadium, niobium, chromium, and zirconium, such as tungsten and titanium, tungsten Binary, ternary or even multi-component alloys composed of vanadium, tungsten and niobium, tungsten and tantalum and chromium, such as alloys composed of 5wt% tungsten, 10wt% niobium, and 85wt% chromium, the coating thickness is 30nm, it is worth explaining The self-healing layer and the super-corrosion-resistant layer are obtained by PVD method, including multi-arc ion coating technology, magnetron sputtering coating technology, and evaporation coating technology, and are not limited to one of them.

[0039] Put the workpiece into the ultrasonic cleaning equipment and perform ultrasonic degreasing cleaning, pure water ultrasonic cleaning, pure water rinsing, water removal, hydrocarbon solvent vacuum ultrasonic cl...

Embodiment 2

[0046] The titanium alloy component of the corrosion-resistant transition layer is a titanium alloy containing 60wt% titanium, wherein titanium is a β phase, and other additives can be one or more of vanadium, tantalum, nickel, chromium, and zirconium, such as titanium and Binary, ternary or even multi-component alloys composed of vanadium, titanium and tantalum, titanium and chromium, titanium and chromium and nickel, such as alloys composed of 60wt% titanium, 20wt% vanadium and 20wt% chromium, and the formed alloy is BCC structure, another alloy that forms the self-healing layer, the composition contains 60wt% tungsten, and other additives can be one or more of titanium, vanadium, niobium, chromium, zirconium, such as tungsten and vanadium, tungsten and Titanium, tungsten and zirconium, tungsten and niobium and chromium, etc., such as an alloy composed of 60wt% tungsten, 10wt% niobium, and 30wt% chromium.

[0047] Put the workpiece into the ultrasonic cleaning equipment and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com