Liquid-phase preparation method for nano lithium fluoride

A lithium fluoride and nanotechnology, which is applied in the field of liquid phase preparation of nanometer lithium fluoride, can solve the problems that solid-state mixing is difficult to achieve sufficient uniformity, and the processes are numerous and complicated, and can inhibit the growth of particle size, the process is simple, and the loss of raw materials can be reduced. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

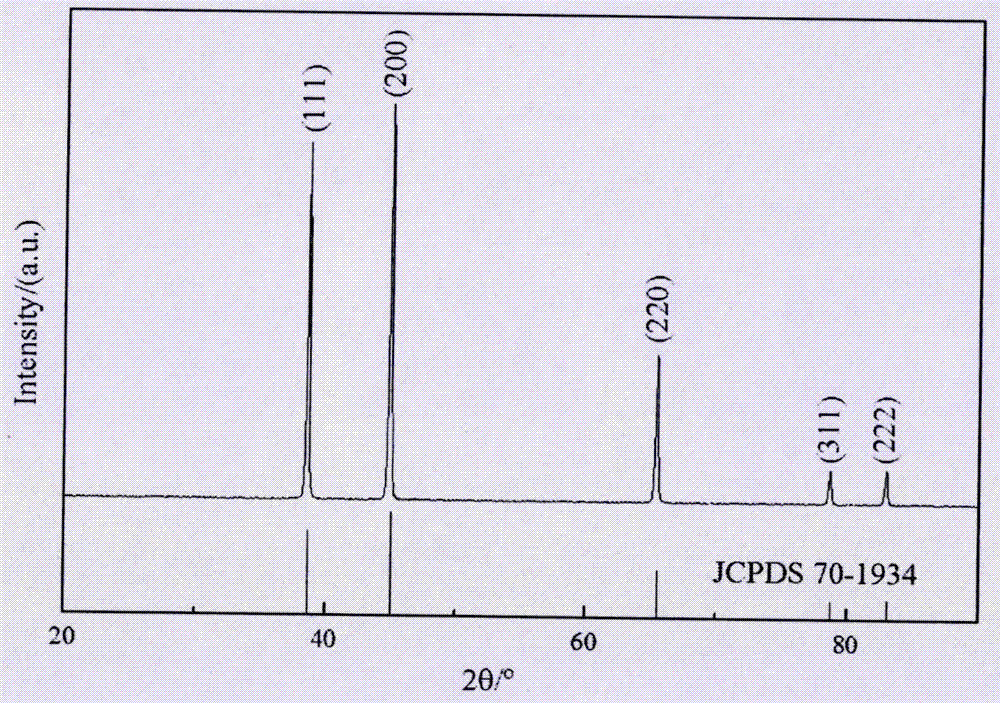

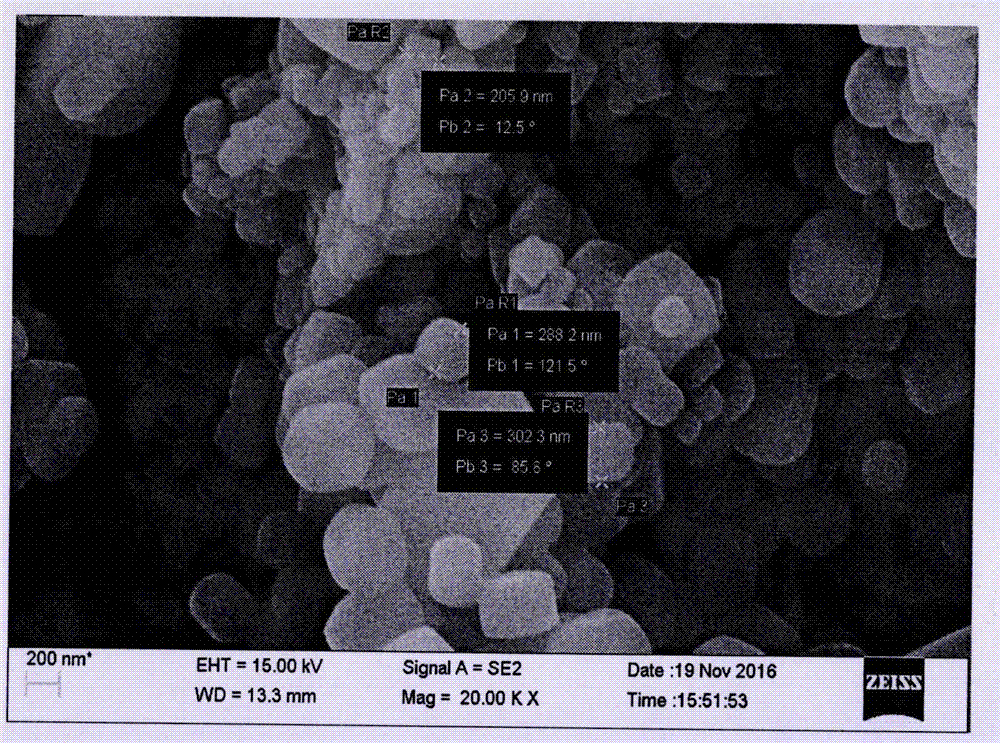

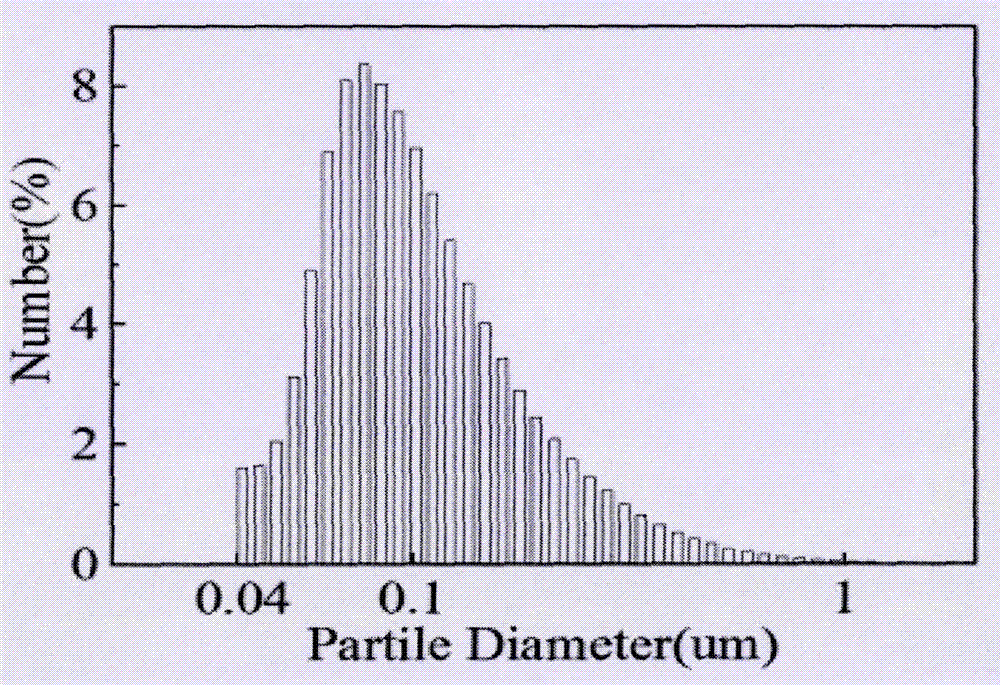

Image

Examples

Embodiment 1

[0029] A method for preparing nano-lithium fluoride in liquid phase, the steps are as follows:

[0030] (1) Calculate according to the preparation of 2gLiF, weigh out LiOH·H according to the stoichiometric ratio of 1:1.1 2 O3.2354g, NH 4 F3.1414g;

[0031] (2) Put the weighed LiOH·H 2 O and NH 4 F is soluble in absolute ethanol with a volume ratio of 1:50;

[0032] (3) Place the solution described in step (2) on a magnetic stirrer and stir, and react. The reaction time is 3 hours; the reacted solution is centrifuged, and the precipitate is taken out and dried at 60°C for 10 hours to prepare precursors The precursor is placed in a corundum ark in a closed and aerated atmosphere furnace, the atmosphere furnace is evacuated to a vacuum state, and then the preparation reaction is carried out at 150°C under the protection of high-purity argon, the reaction time is 10 hours; the reaction is over Afterwards, the furnace temperature was raised to 300°C, and the high-purity argon gas was use...

Embodiment 2

[0035] A method for preparing nano-lithium fluoride in liquid phase, the steps are as follows:

[0036] (1) Calculate according to the preparation of 2gLiF, weigh out LiOH·H according to the stoichiometric ratio of 1:1.1 2 O3.2354g, NH 4 F3.1414g;

[0037] (2) Put the weighed LiOH·H 2 Place O in a polytetrafluoroethylene beaker, add absolute ethanol to prepare a solution with a volume ratio of 1:50, and place it on a magnetic stirrer for 3 hours;

[0038] (3) In step (2), the weighed NH 4 F is gradually added to LiOH·H 2 O in anhydrous ethanol solution (add 0.449g every 20 minutes, the total mass is 3.1414g, until the addition is complete); after the reaction, the solution is centrifuged, the precipitate is taken out and dried at 60°C for 10h to prepare the precursor; the precursor is used The corundum ark is placed in a closed and ventilated atmosphere furnace, the atmosphere furnace is evacuated to a vacuum state, and then the preparation reaction is carried out at 150°C under the ...

Embodiment 3

[0041] A method for preparing nano-lithium fluoride in liquid phase, the steps are as follows:

[0042] (1) Calculate according to the preparation of 2gLiF, weigh out LiOH·H according to the stoichiometric ratio of 1:1.1 2 O3.2354g, NH 4 F3.1414g;

[0043] (2) Put the weighed LiOH·H 2 O and NH 4 F is soluble in absolute ethanol with a volume ratio of 1:100;

[0044] (3) Place the solution described in step (2) on a magnetic stirrer and stir, and react. The reaction time is 3 hours; the reacted solution is centrifuged, and the precipitate is taken out and dried at 60°C for 10 hours to prepare precursors The precursor is placed in a corundum ark in a closed and aerated atmosphere furnace, the atmosphere furnace is evacuated to a vacuum state, and then the preparation reaction is carried out at 150°C under the protection of high-purity argon, the reaction time is 10 hours; the reaction is over Afterwards, the furnace temperature was raised to 300°C, and the high-purity argon gas was us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com