Irregularly-arrayed multiple-contact large-current elastic contact terminal

An elastic contact and high current technology, applied in the direction of contact parts, can solve the problems of concentrated contact area, large insertion force, and unsatisfactory heat dissipation effect, so as to reduce heat generation, easy and soft docking, improve current carrying capacity and The effect of connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

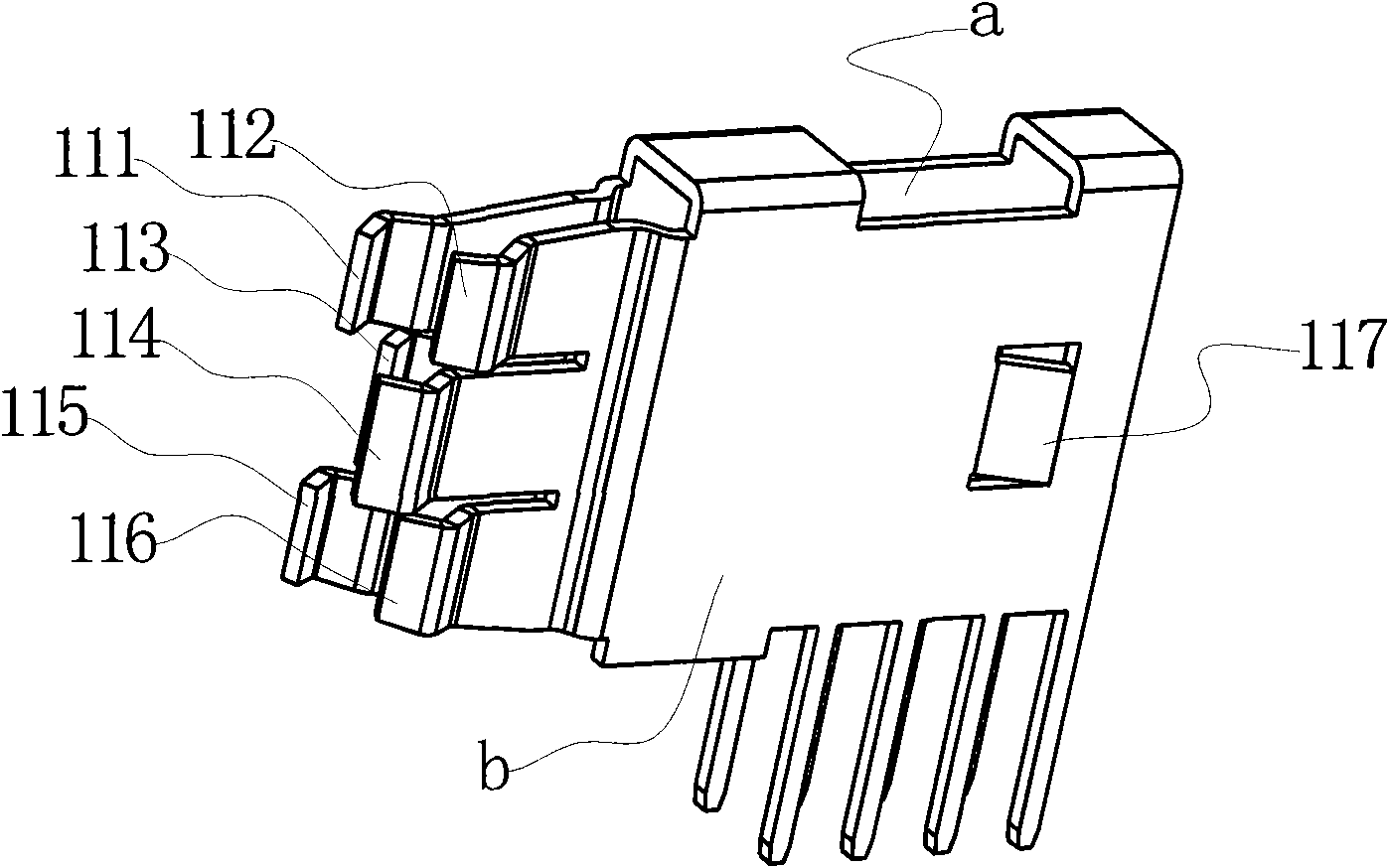

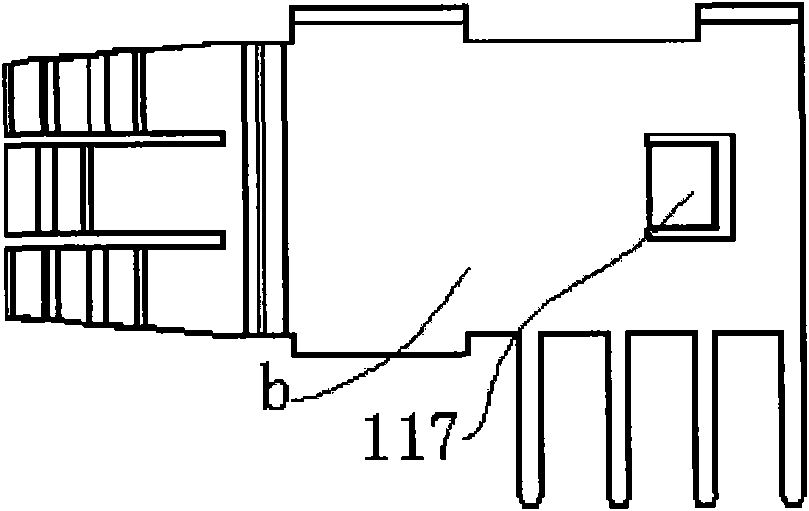

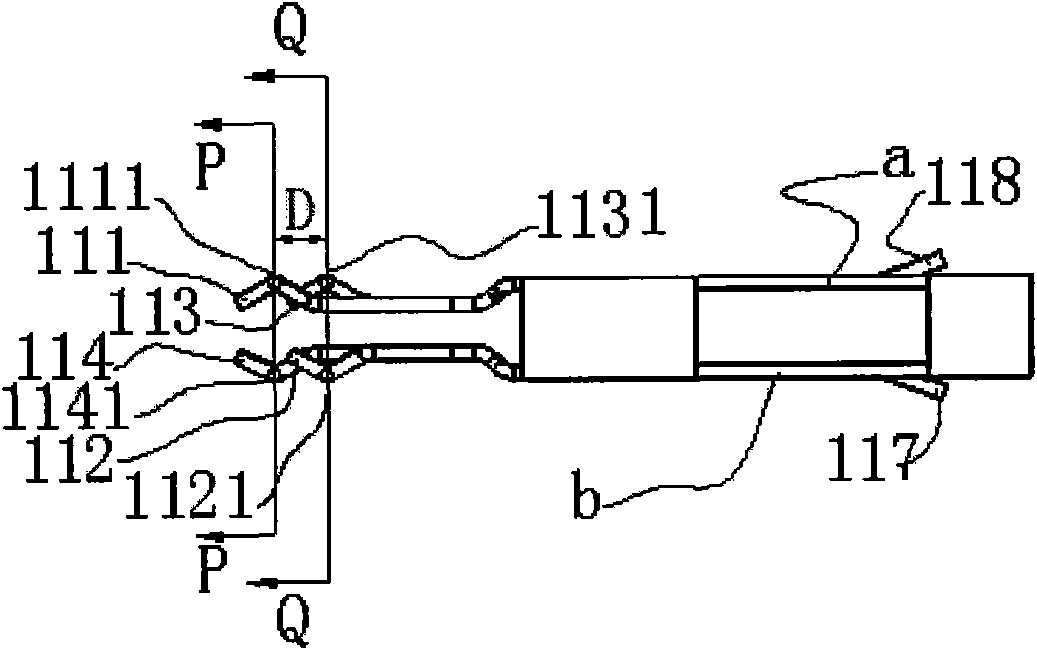

[0019] Example: such as figure 1 , figure 2 , image 3 , Figure 6 As shown, a large-current elastic contact terminal with multiple contacts in a staggered arrangement, the butt end of the contact terminal includes six contact pieces 111, 112, 113, 114, 115 and 116, and each contact piece is provided with Corresponding contact areas 1111 , 1121 , 1131 , 1141 , 1151 and 1161 . The above-mentioned contact pieces are staggeredly distributed on the a-side and b-side of the contact member, and the contact pieces 111, 114 and 115 are of the same length during blanking, which are defined as long contact pieces, and the corresponding contact areas are defined as long contact areas. Sheets 112, 113, and 116 are equal in length during blanking, and are defined as short contact sheets, and the corresponding contact areas are defined as short contact areas, and the gap between long and short contact sheets is d. Refer to Figure 6 . After the sheet metal is formed, the long contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com