A polymer monofilament liquid applying (oil applying, functional sizing agent applying and wrapping) device

A polymer and monofilament technology, applied in the field of polymer monofilament liquid filling device, can solve the problems of increased driving load, unfavorable winding process, complex design of oiling rollers and wheels, etc., to prevent mutual merger or interference, increase Larger contact area, improved efficiency and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

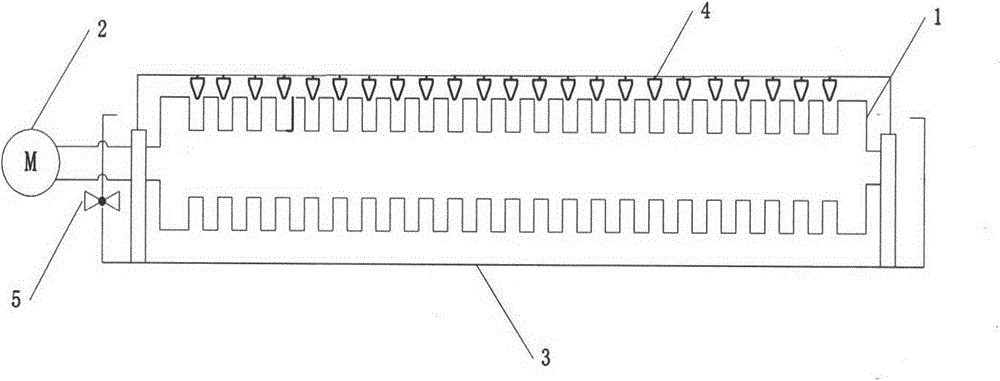

[0021] Such as picture As shown in 1, a polymer monofilament filling (oiling, functional slurry and coating) device is characterized in that it mainly includes 1 filling, a guide wire channel assembly, 2 a liquid guide wire assembly driving device, 3 storage Liquid components, 4 liquid quantitative delivery components and 5 overflow components. The surface of the upper liquid and guide wire channel is rectangular planar, with a width of 0.05mm and a depth of 0.5cm, and its carrier is in the shape of a roller; the liquid quantitative delivery component can be used to uniformly feed the monofilament with a large wrap angle (270°) on a rectangular cross section. liquid.

[0022] A polymer monofilament coating (oiling, functional slurry and coating) device described in this embodiment has dual functions, and the design of the coating and guide wire channel is beneficial to the uniformity of monofilament oiling , and at the same time have the function of separating and guiding wi...

Embodiment 2

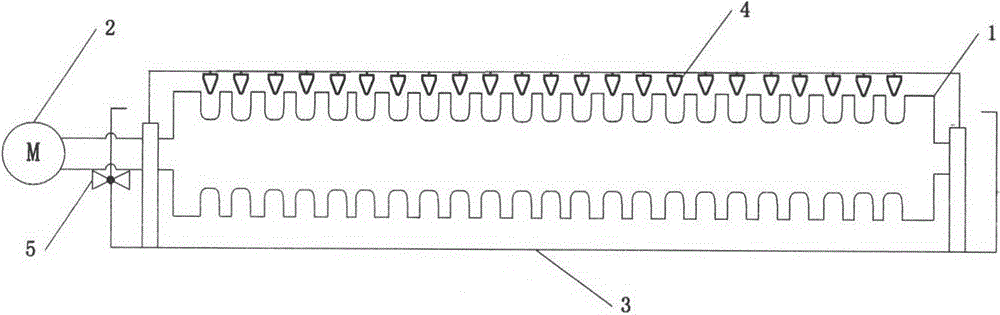

[0024] Such as picture As shown in 2, a polymer monofilament liquid (oiling, functional slurry and coating) device is characterized in that it mainly includes 1 liquid application, guide wire channel assembly, 2 liquid application guide wire assembly driving device, 3 storage Liquid components, 4 liquid quantitative delivery components and 5 overflow components. The surface of the upper liquid and the guide wire channel is semicircular, with a width of 0.5mm and a depth of 0.7cm, and its carrier is in the shape of a roller; the liquid quantitative delivery component can wrap a large angle (270° ) evenly on the liquid.

[0025] Others are the same as embodiment 1.

Embodiment 3

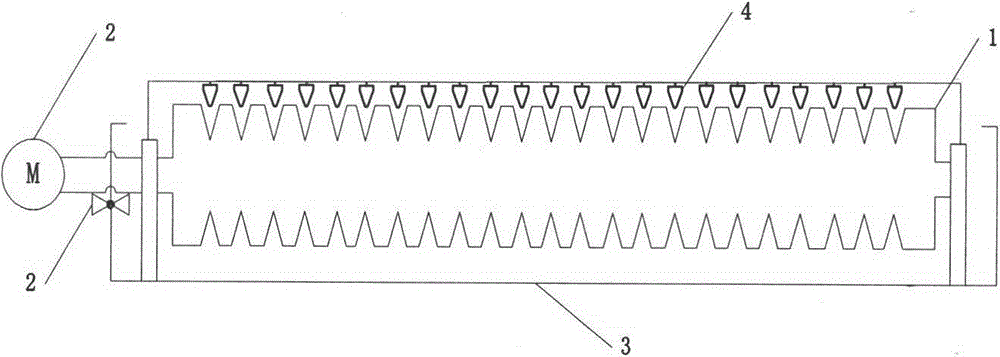

[0027] Such as picture As shown in 3, a device for applying liquid (oiling, functional slurry and coating) to polymer monofilament, its features mainly include 1 liquid application, guide wire channel assembly, 2 liquid application guide wire assembly driving device, 3 storage Liquid components, 4 liquid quantitative delivery components and 5 overflow components. The surface of the upper liquid and guide wire channel is triangular planar, with a width of 1.2mm and a depth of 0.7mm, and its carrier is in the shape of a roller; the liquid quantitative delivery component can be used to wrap the monofilament with a large angle (270°) evenly in a triangular cross-section Upper liquid. Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com