Hydrotreating catalyst and preparation method thereof

A hydrogenation treatment and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of high price of active metal components, low utilization rate of active components, and catalyst selection To solve the problems such as the reduction of property, achieve the effect of reasonable distribution of components, high utilization rate and inhibition of diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

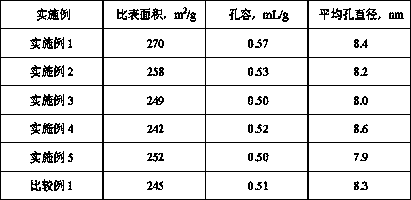

Embodiment 1

[0033] (1) Preparation of Mo-Ni-P aqueous solution:

[0034] 7.0g phosphoric acid H 3 PO 4 (concentration 85 wt%) was dissolved in 80mL of water, then added 23.8g of molybdenum trioxide and 8.8g of basic nickel carbonate, heated to 100°C, stirred and refluxed for 2.0h, and filtered to 100mL to obtain Mo-Ni-P aqueous solution. where MoO 3 The concentration of NiO is 0.23g / mL, the concentration of NiO is 0.046g / mL, and the concentration of P is 0.019g / mL.

[0035] (2) Preparation of catalyst:

[0036] 79.3g of amorphous silica-alumina carrier (silica content 20wt%, pore volume 0.78mL / g, specific surface area 320m 2 / g, cylinder, diameter 0.8mm) and 550g of n-decane solution were added to the autoclave, heated to 400°C, and reacted for 3h. After the reaction, the catalyst was filtered out and dried at 30°C until there was no liquid on the surface of the carrier phase to obtain catalyst precursor A; then add it to an aqueous solution containing 100.0g citric acid, let it sta...

Embodiment 2

[0042] (1) Preparation of Mo-Ni-P aqueous solution:

[0043] 8.7g phosphoric acid H 3 PO 4 (concentration 85 wt%) was dissolved in 80mL of water, then added 30.3g of molybdenum trioxide and 11.2g of basic nickel carbonate, heated to 100°C and stirred and refluxed for 2.0h, filtered and set to 100mL to obtain Mo-Ni-P aqueous solution. where MoO 3 The concentration of NiO was 0.30 g / mL, that of NiO was 0.06 g / mL, and that of P was 0.023 g / mL.

[0044] (2) Preparation of catalyst:

[0045] 75.2g of amorphous silica-alumina carrier (silica content 20wt%, pore volume 0.78mL / g, specific surface area 320m 2 / g, cylinder, diameter 0.8mm) and 550g of n-decane solution were added to the autoclave, heated to 400°C, and reacted for 3h. After the reaction, the catalyst was filtered out and dried at 30°C until there was no liquid on the surface of the carrier phase to obtain catalyst precursor A; then add it to an aqueous solution containing 100.0g citric acid, let it stand for 5min, ...

Embodiment 3

[0051] (1) Preparation of Mo-Ni-P aqueous solution:

[0052] 10.2g phosphoric acid H 3 PO 4 (concentration 85 wt%) was dissolved in 80mL of water, then added 34.8g of molybdenum trioxide and 12.8g of basic nickel carbonate, heated to 100°C and stirred and refluxed for 2.0h, filtered and set to 100mL to obtain Mo-Ni-P aqueous solution. where MoO 3 The concentration of NiO was 0.34 g / mL, that of NiO was 0.069 g / mL, and that of P was 0.03 g / mL.

[0053] (2) Preparation of catalyst:

[0054] 72.3g of amorphous silica-alumina carrier (silica content 20wt%, pore volume 0.78mL / g, specific surface area 320m 2 / g, cylinder, diameter 0.8mm) and 550g of n-decane solution were added to the autoclave, heated to 400°C, and reacted for 3h. After the reaction, the catalyst was filtered out and dried at 30°C until there was no liquid on the surface of the carrier phase to obtain catalyst precursor A; then add it to an aqueous solution containing 100.0g citric acid, let it stand for 5min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com