A kind of zirconium scandium composite oxide coated lithium titanate negative electrode material and preparation method thereof

A composite oxide and lithium titanate coating technology, which is applied to battery electrodes, electrochemical generators, structural parts, etc., can solve the problem of increased electrode/electrolyte interface impedance, affecting the application of lithium titanate, and shortening battery life. Problems, to achieve the effect of improving the rate and cycle performance, easy to test, and suppressing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a zirconium-scandium composite oxide-coated lithium titanate negative electrode material proposed by the present invention comprises the following steps:

[0027] S1. Weigh lithium hydroxide, tetrabutyl titanate, zirconium tetrachloride and scandium nitrate according to the molar ratio of Li:Ti:Zr:Sc=4:5:0.05:0.02 and add them to the solution containing 1wt% Ultrasonic treatment for 1 hour in an absolute ethanol solution of citric acid, wherein the amount of citric acid added is 1 wt% of the theoretically synthesized lithium titanate, then heated to 60° C. and stirred for 2 hours to form a gel;

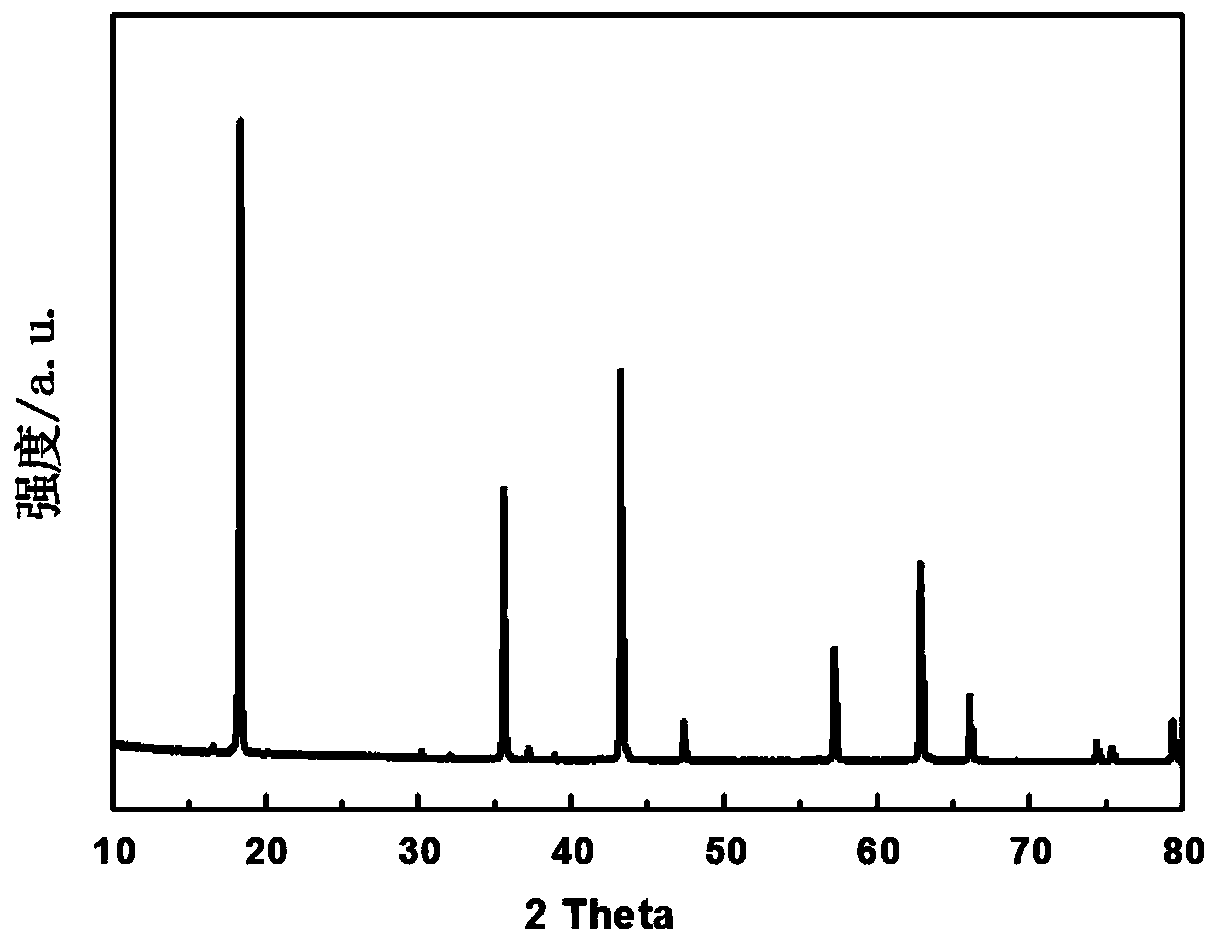

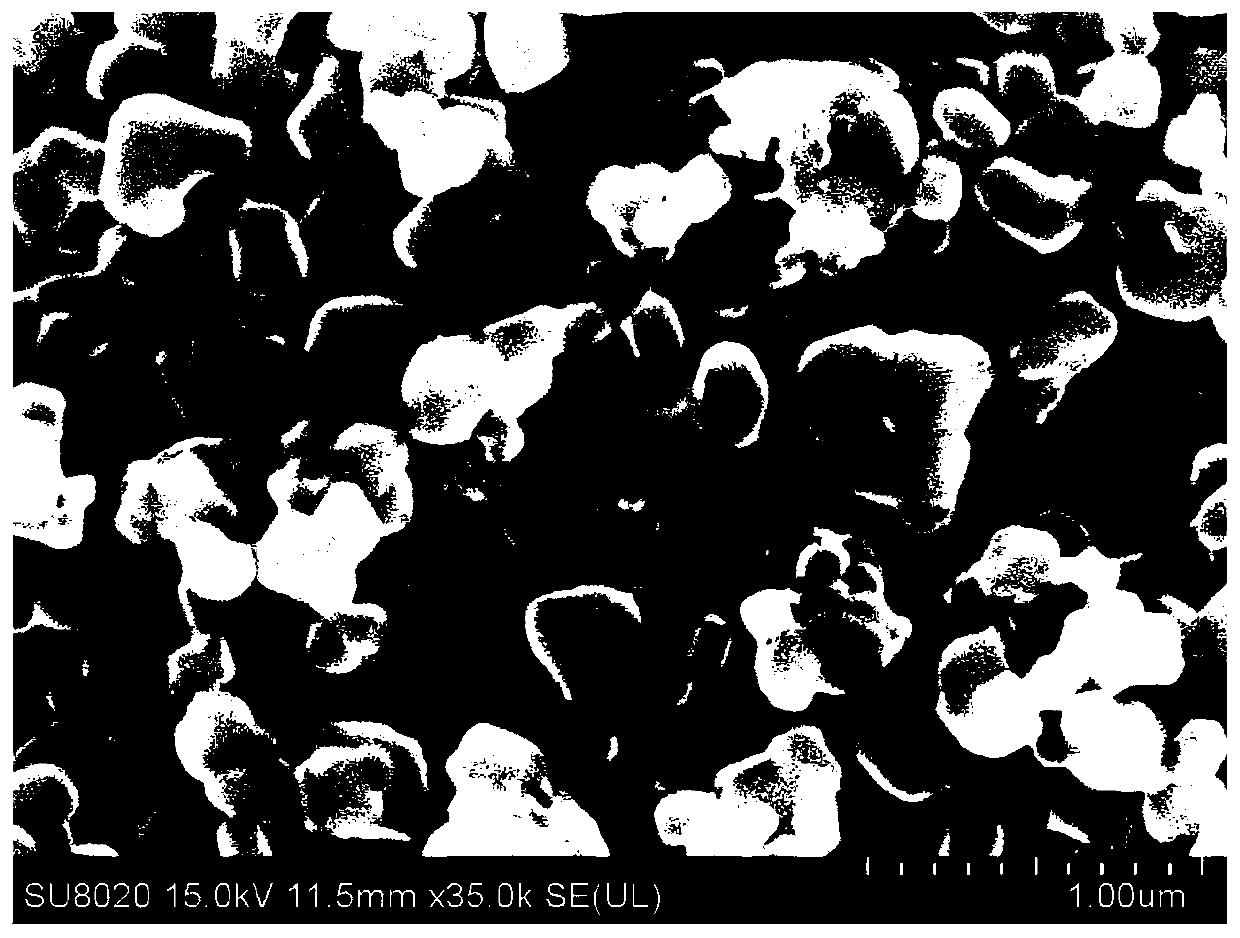

[0028] S2. Dry the gel obtained in S1 at 100°C and grind it, then pre-calcine at 400°C for 3 hours, then calcinate at 650°C for 5 hours, and cool naturally to room temperature to obtain the Zr 5 sc 2 o 13 Coated lithium titanate negative electrode material.

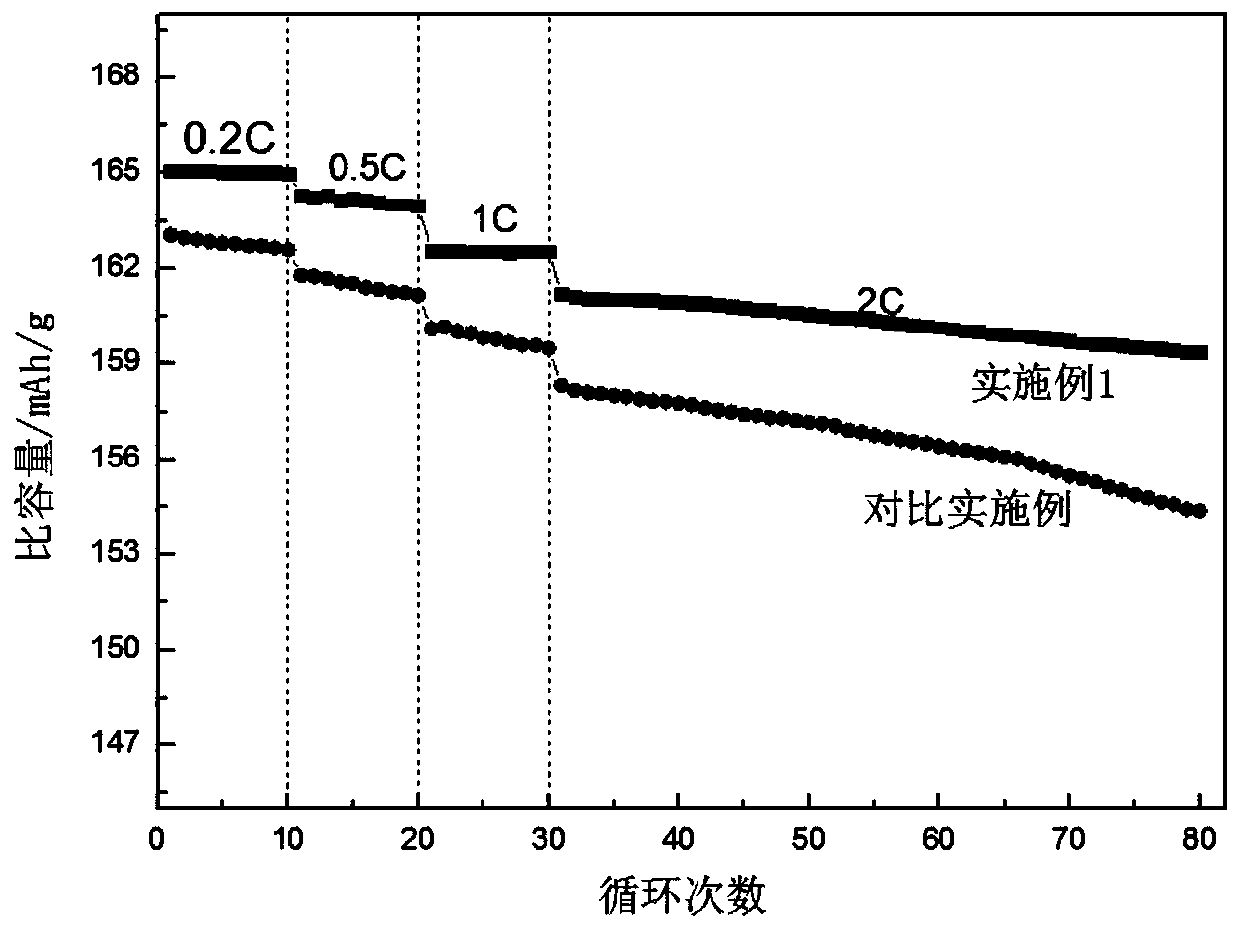

[0029] Zr prepared in this embodiment 5 sc 2 o 13 The 0.2C rate discharge specific capacity...

Embodiment 2

[0031] A method for preparing a zirconium-scandium composite oxide-coated lithium titanate negative electrode material proposed by the present invention comprises the following steps:

[0032] S1. Weigh lithium acetate, tetraethyl titanate, zirconium nitrate and scandium chloride according to the ratio of Li:Ti:Zr:Sc=4.05:5:0.1:0.04 according to the molar ratio. Ultrasonic treatment in absolute ethanol solution for 1.2h, wherein the amount of citric acid added is 2wt% of the theoretically synthesized lithium titanate, then heated to 65°C and stirred for 4h to form a gel;

[0033] S2. Dry the gel obtained in S1 at 105°C and grind it, then pre-calcine at 450°C for 4 hours, then calcinate at 700°C for 6 hours, and cool naturally to room temperature to obtain the Zr 5 sc 2 o 13 Coated lithium titanate negative electrode material.

[0034] Zr prepared in this embodiment 5 sc 2 o 13The 0.2C rate charging specific capacity of the coated lithium titanate negative electrode mater...

Embodiment 3

[0036] A method for preparing a zirconium-scandium composite oxide-coated lithium titanate negative electrode material proposed by the present invention comprises the following steps:

[0037] S1, according to the molar ratio of Li:Ti:Zr:Sc=4.1:5:0.15:0.06, weigh lithium nitrate, tetraisopropyl titanate, zirconium oxide and scandium oxide and add to the solution containing 5wt% citric acid Ultrasonic treatment in absolute ethanol solution for 1.5h, wherein the amount of citric acid added was 5wt% of the theoretically synthesized lithium titanate, then heated to 75°C and stirred for 6h to form a gel;

[0038] S2. Dry the gel obtained in S1 at 110°C and grind it, then pre-calcine at 500°C for 4 hours, then calcinate at 750°C for 8 hours, and cool naturally to room temperature to obtain the Zr 5 sc 2 o 13 Coated lithium titanate negative electrode material.

[0039] Zr prepared in this embodiment 5 sc 2 o 13 The 0.2C rate charging specific capacity of the coated lithium tit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com