Vanadium-doped ZnO nanorod array photo-anode, and preparation method and application thereof

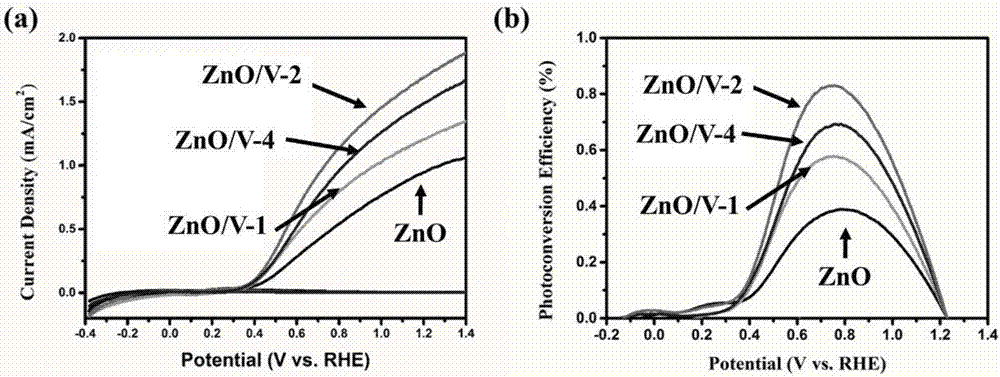

A nanorod array, photoanode technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as limiting photoanode performance, reduce recombination, and improve photoelectrochemical water splitting performance. , the effect of reducing the density of surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

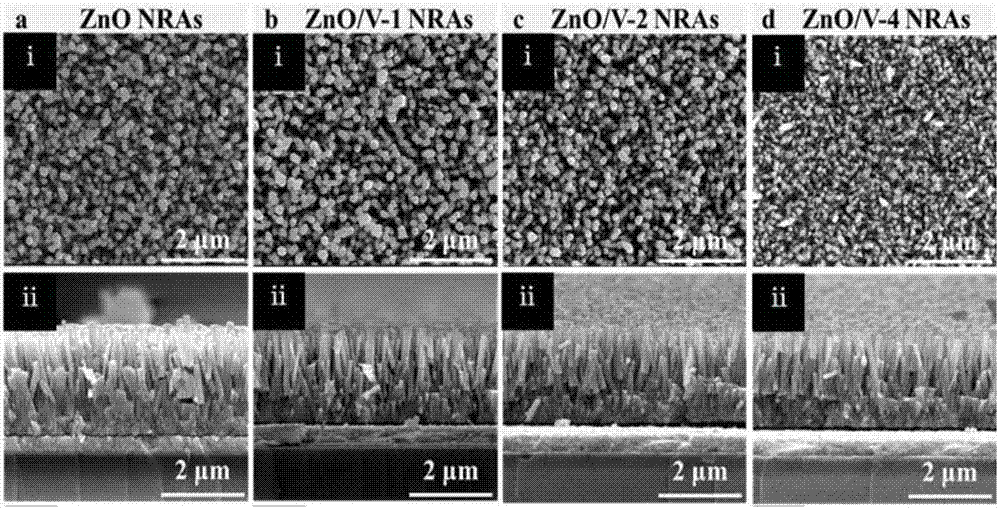

[0032] A method for preparing a vanadium-doped zinc oxide nanorod array photoanode, the method comprising the following steps:

[0033] (1) Prepare and obtain ZnO seed liquid, vanadium doping solution and growth solution respectively;

[0034] The preparation of the ZnO seed liquid is specifically: dissolving zinc acetate and ethanolamine in ethylene glycol monomethyl ether to prepare a ZnO seed liquid with a concentration of 0.5 M; wherein the molar mass ratio of zinc acetate and ethanolamine is :1:1;

[0035] The preparation method of the vanadium-doped solution is as follows: dissolving vanadium pentoxide in deionized water and ultrasonicating for 48 hours to obtain the vanadium-doped solution with a concentration of 1 mM;

[0036] The preparation method of the growth solution specifically includes: dissolving zinc nitrate hexahydrate and hexamethylenetetramine in deionized water to obtain the growth solution with a concentration of 50 mM, wherein the zinc nitrate hexahydr...

Embodiment 2

[0042] It is basically the same as Example 1, except that in step (3), when preparing the mixed solution, the volume ratio of the vanadium-doped solution to the growth solution is 2:40.

Embodiment 3

[0044]It is basically the same as Example 1, except that in step (3), when preparing the mixed solution, the volume ratio of the vanadium-doped solution and the growth solution is 3:40.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com