A kind of semiconductive material for ultra-low temperature resistant cable

A semi-conductive, low-temperature resistant technology, applied in rubber insulators, organic insulators, etc., can solve problems such as embrittlement cracks, uneven electric field, breakdown, etc., and achieve the effect of good retraction performance and good bending performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

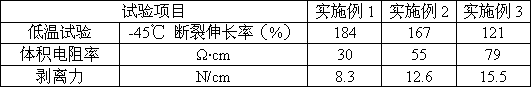

specific Embodiment 1

[0019] A semi-conductive material for ultra-low temperature resistant cables disclosed by the present invention consists of 50 parts of nitrile rubber, 30 parts of neoprene rubber, 20 parts of ethylene vinyl acetate rubber, 1 part of anti-aging agent 4010NA, 3 parts of vaseline, and 1 part of TMTD , 1 part of DM, 0.2 parts of sulfur, 1.5 parts of dicumyl peroxide, 6 parts of zinc oxide, 4 parts of magnesium oxide, 55 parts of carbon black N330, 40 parts of conductive carbon black, and 12 parts of plasticizer. The method of two-stage vulcanization is adopted to ensure that the rubber has a long enough scorch time during continuous vulcanization. In the continuous sulfur extrusion process, the extruder temperature was set at 50-75°C, the vulcanization steam pressure was 1.3 MPa, and the traction speed was 14m / min to obtain the finished product. The volume resistivity of the finished wire core is 30Ω·cm, which can be easily peeled off from the insulation, and the elongation rate ...

specific Embodiment 2

[0020] A semi-conductive material for ultra-low temperature resistant cables disclosed by the present invention is selected from 55 parts of nitrile rubber, 25 parts of neoprene rubber, 30 parts of ethylene vinyl acetate rubber, 1.5 parts of anti-aging agent 4010NA, 4 parts of vaseline, and 1.5 parts of TMTD 1.5 parts of DM, 0.4 parts of sulfur, 2 parts of dicumyl peroxide, 4.5 parts of zinc oxide, 3 parts of magnesium oxide, 48 parts of carbon black N330, 30 parts of conductive carbon black, and 10 parts of plasticizer. The method of two-stage vulcanization is adopted to ensure that the rubber has a long enough scorch time during continuous vulcanization. In the continuous sulfur extrusion process, the extruder temperature was set at 50-75°C, the vulcanization steam pressure was 1.4 MPa, and the traction speed was 15m / min to obtain the finished product. The volume resistivity of the finished wire core is 55Ω·cm, which can be easily peeled off from the insulation, and the elon...

specific Embodiment 3

[0021] A semi-conductive material for ultra-low temperature resistant cables disclosed by the present invention consists of 60 parts of nitrile rubber, 20 parts of neoprene rubber, 10 parts of ethylene vinyl acetate rubber, 2 parts of anti-aging agent 4010NA, 5 parts of vaseline, and 2 parts of TMTD , 2 parts of DM, 0.5 parts of sulfur, 1 part of dicumyl peroxide, 3 parts of zinc oxide, 2 parts of magnesium oxide, 40 parts of carbon black N330, 20 parts of conductive carbon black, and 8 parts of plasticizer. The method of two-stage vulcanization is adopted to ensure that the rubber has a long enough scorch time during continuous vulcanization. In the continuous sulfur extrusion process, the extruder temperature was set at 50-75°C, the vulcanization steam pressure was 1.5 MPa, and the traction speed was 16m / min to obtain the finished product. The volume resistivity of the finished wire core is 79Ω·cm, which can be easily peeled off from the insulation, and the elongation rate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com