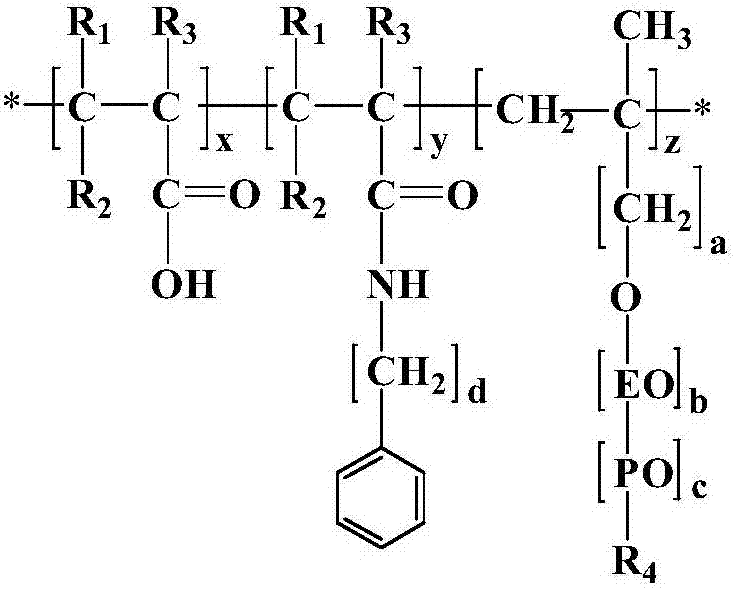

Slow-release polycarboxylate superplasticizer and preparation method thereof

A slow-release polycarboxylate and superplasticizer technology, which is applied in the field of polycarboxylate superplasticizers for cement concrete, can solve the problems of no esterification reaction, low conversion rate of high-performance superplasticizers, and difficulty in process control Large and other problems, to achieve the effects of weakening interspersed adsorption, improving sensitivity, and improving dispersion retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

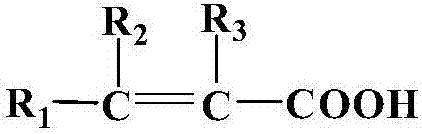

Method used

Image

Examples

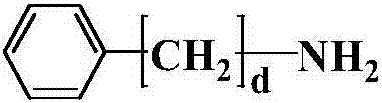

Embodiment 1

[0036] Partially react 1 mol of acrylic acid with 0.6 mol of diphenylphosphoryl chloride to obtain unsaturated small monomers containing phosphate groups, and then add 0.6 mol of phenylethylamine to the above reaction system to react with phosphate groups to obtain amide group-containing unsaturated monomers. Unsaturated small monomer, and then with 5mol methallyl polyoxyethylene ether, under the action of 0.01mol sodium persulfate, 0.03mol sodium metabisulfite and 0.01mol sodium methacrylsulfonate, keep at 50 ℃ for free radical Polymerize for 3 hours to obtain a copolymer product, adjust the pH value of the copolymer product to 6.5 with sodium hydroxide, and add water to obtain a polycarboxylate water reducer with a mass concentration of 40%.

Embodiment 2

[0038] Partially react 1 mol of methacrylic acid with 0.8 mol of diphenylphosphoryl chloride to obtain unsaturated small monomers containing phosphate groups, and then add 0.8 mol of aniline to the above reaction system to react with phosphate groups to obtain amide group-containing unsaturated monomers. Small unsaturated monomers, and 1.2 mol isoprenyl polyoxyethylene ether, under the action of 0.02 mol potassium persulfate, 0.1 mol sodium sulfite and 0.02 mol mercaptopropanol, kept at 25 ° C for 5 hours to obtain For the copolymerization product, adjust the pH value of the copolymerization product to 6.0 with calcium hydroxide, and add water to obtain a polycarboxylate water reducer with a mass concentration of 15%.

Embodiment 3

[0040]Partially react 1mol maleic acid with 0.2mol diphenylphosphoryl chloride to obtain unsaturated small monomers containing phosphate groups, then add 0.2mol phenethylamine to the above reaction system to react with phosphate groups to obtain amide group-containing group of unsaturated small monomers, and then with 8mol methallyl polyoxyethylene propylene ether under the action of 0.05mol hydrogen peroxide, 0.2mol ferrous pyrophosphate and 0.05mol mercaptoacetic acid, keep at 30 ℃ for free radical The copolymerization product was obtained after the polymerization reaction for 4 hours, and the pH value of the copolymerization product was adjusted to 7 with sodium hydroxide, and water was added to obtain a polycarboxylic acid-based water reducer with a mass concentration of 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com