Separation process for copper sulphide ore with superfine disseminated grain sizes

A copper sulfide ore and particle size technology, which is applied in flotation, solid separation, grain processing, etc., can solve the problems of reducing the grade and recovery rate of concentrate products, wide product particle size distribution, and flotation slurry with more mud, and achieves improvement. Flotation environment, improve the concentrate grade, and benefit the effect of subsequent smelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

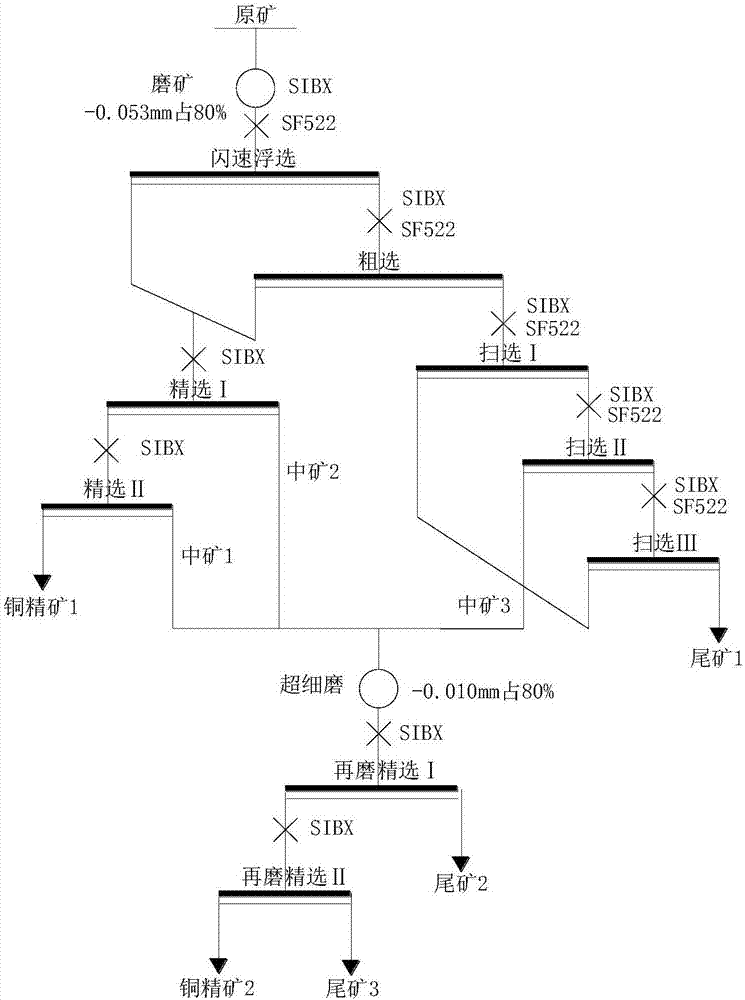

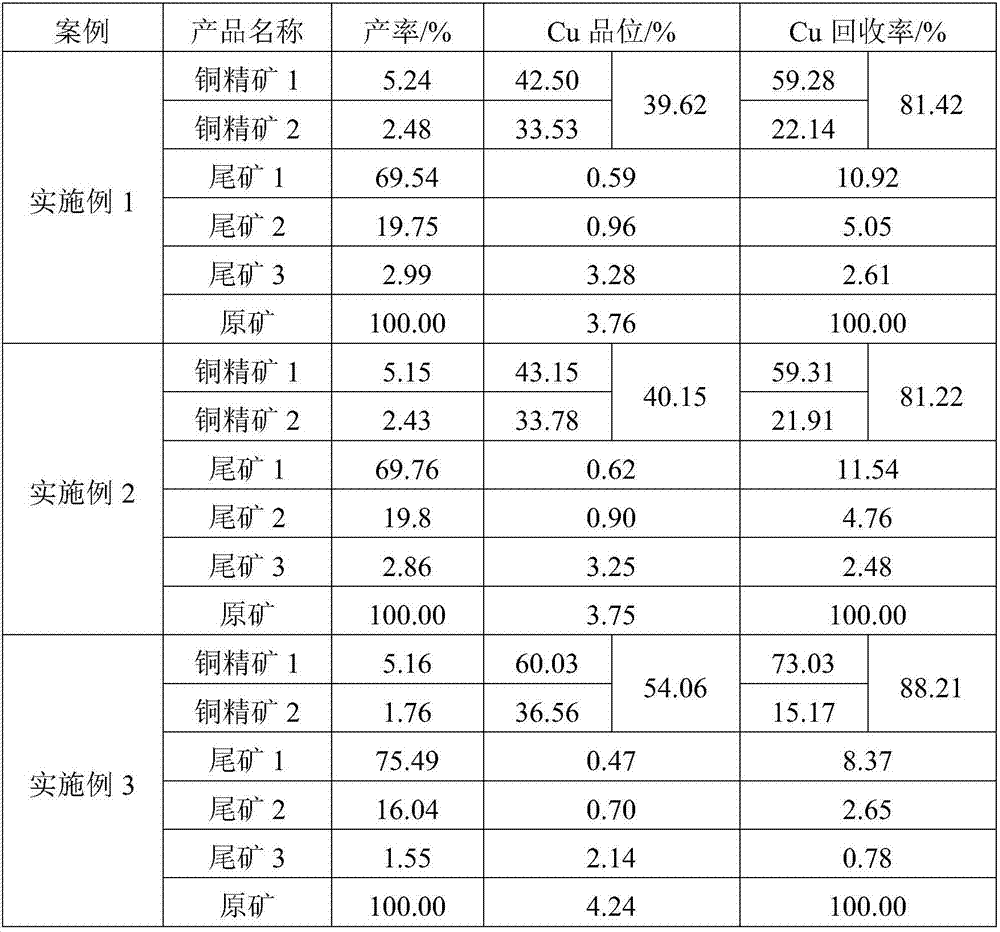

[0039] The copper ore used in embodiment 1 belongs to copper sulfide ore, the main copper minerals are chalcopyrite and chalcocite, and the raw ore contains 3.76% copper (wt%). According to the dry weight of each ton of raw ore, the crushed raw ore and water are first added to the rod mill at a ratio of 1:1 for grinding, and the amount of collector SIBX is added to 120g / t during the grinding, and the discharge of the rod mill Grinding fineness reaches -0.053mm (fineness less than or equal to 0.053mm) accounting for 80%. Add foaming agent SF522 dosage 65g / t to ball mill discharge, and perform flash flotation to obtain flash flotation concentrate and flash flotation tailings; add collector SIBX dosage 18g / t to flash flotation tailings in turn Copper roughing with foaming agent SF522 at 10g / t to obtain copper roughing concentrate and copper roughing tailings, combined with flash flotation concentrate and copper roughing concentrate, adding collector SIBX at 10g / t Concentration I...

Embodiment 2

[0041] The copper ore used in embodiment 2 belongs to copper sulfide ore, and the main copper minerals are chalcopyrite and chalcocite, and the raw ore contains 3.75% copper (wt%). According to the dry weight of each ton of raw ore, the crushed raw ore and water are first added to the rod mill at a ratio of 1:1 for grinding, and the amount of collector SIBX is added to 110g / t during the grinding, and the discharge of the rod mill Grinding fineness reaches -0.053mm, accounting for 80%. Add foaming agent SF522 dosage 60g / t to ball mill discharge, and perform flash flotation to obtain flash flotation concentrate and flash flotation tailings; add collector SIBX dosage 17g / t to flash flotation tailings in turn Copper roughing with foaming agent SF522 at 10g / t to obtain copper roughing concentrate and copper roughing tailings, combined with flash flotation concentrate and copper roughing concentrate, adding collector SIBX at 10g / t Concentration I is carried out to obtain the concen...

Embodiment 3

[0043] The copper ore used in Example 3 belongs to copper sulfide ore, the main copper mineral is chalcocite, and the raw ore contains 4.24% copper (wt%). According to the dry weight of each ton of raw ore, the crushed raw ore and water are first added to the rod mill at a ratio of 1:1 for grinding, and the amount of collector SIBX is added to 110g / t during the grinding, and the discharge of the rod mill Grinding fineness reaches -0.053mm, accounting for 80%. Add foaming agent SF522 dosage 60g / t to ball mill discharge, and perform flash flotation to obtain flash flotation concentrate and flash flotation tailings; add collector SIBX dosage 17g / t to flash flotation tailings in turn Copper roughing with foaming agent SF522 at 10g / t to obtain copper roughing concentrate and copper roughing tailings, combined with flash flotation concentrate and copper roughing concentrate, adding collector SIBX at 10g / t Concentration I is carried out to obtain the concentrate I and middle ore 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com