A method for measuring four components of coal tar

A coal tar and four-component technology, which is applied in the direction of measuring devices, material separation, and analysis of materials, can solve problems such as inability to elute out and errors in experimental results, achieve sufficient extraction, increase contact area, and facilitate accurate measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

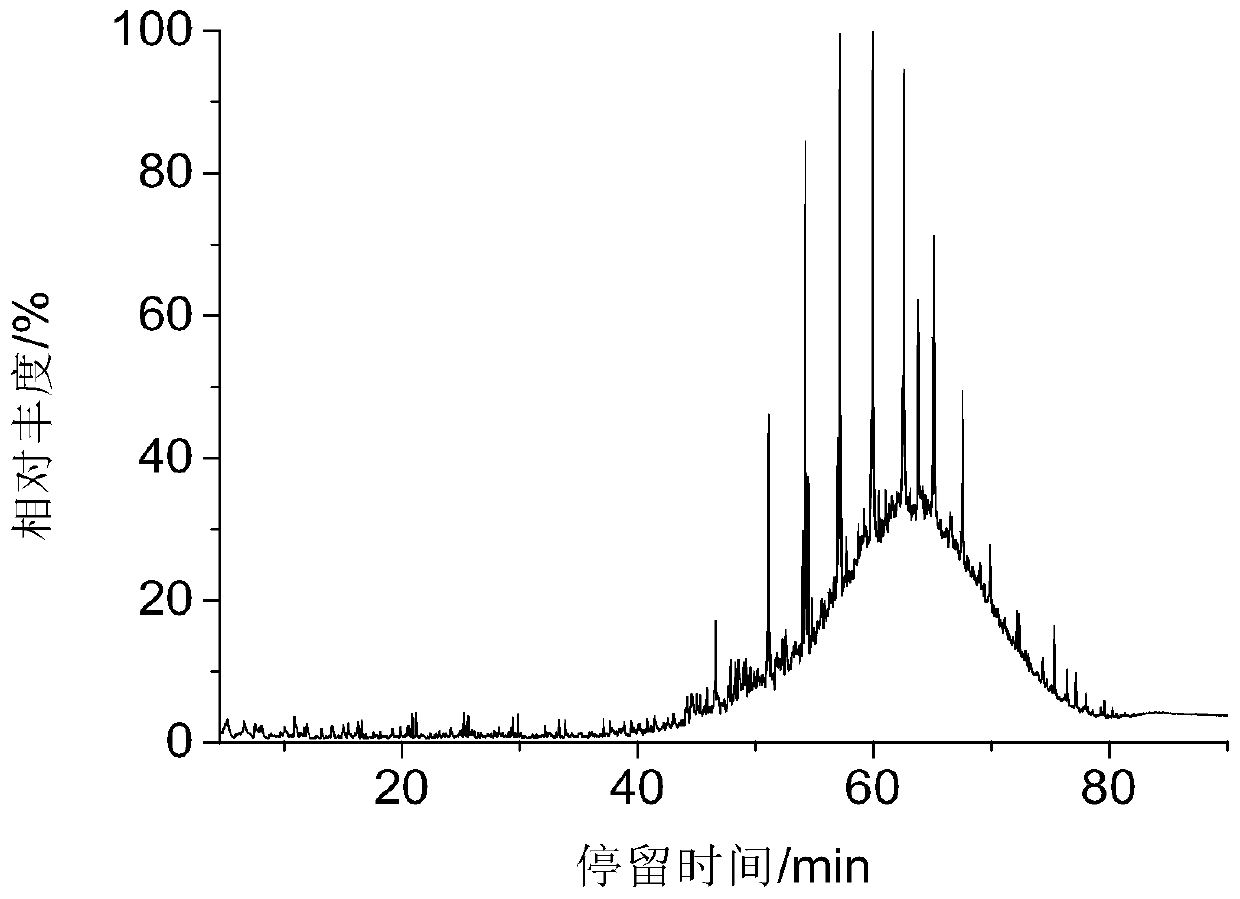

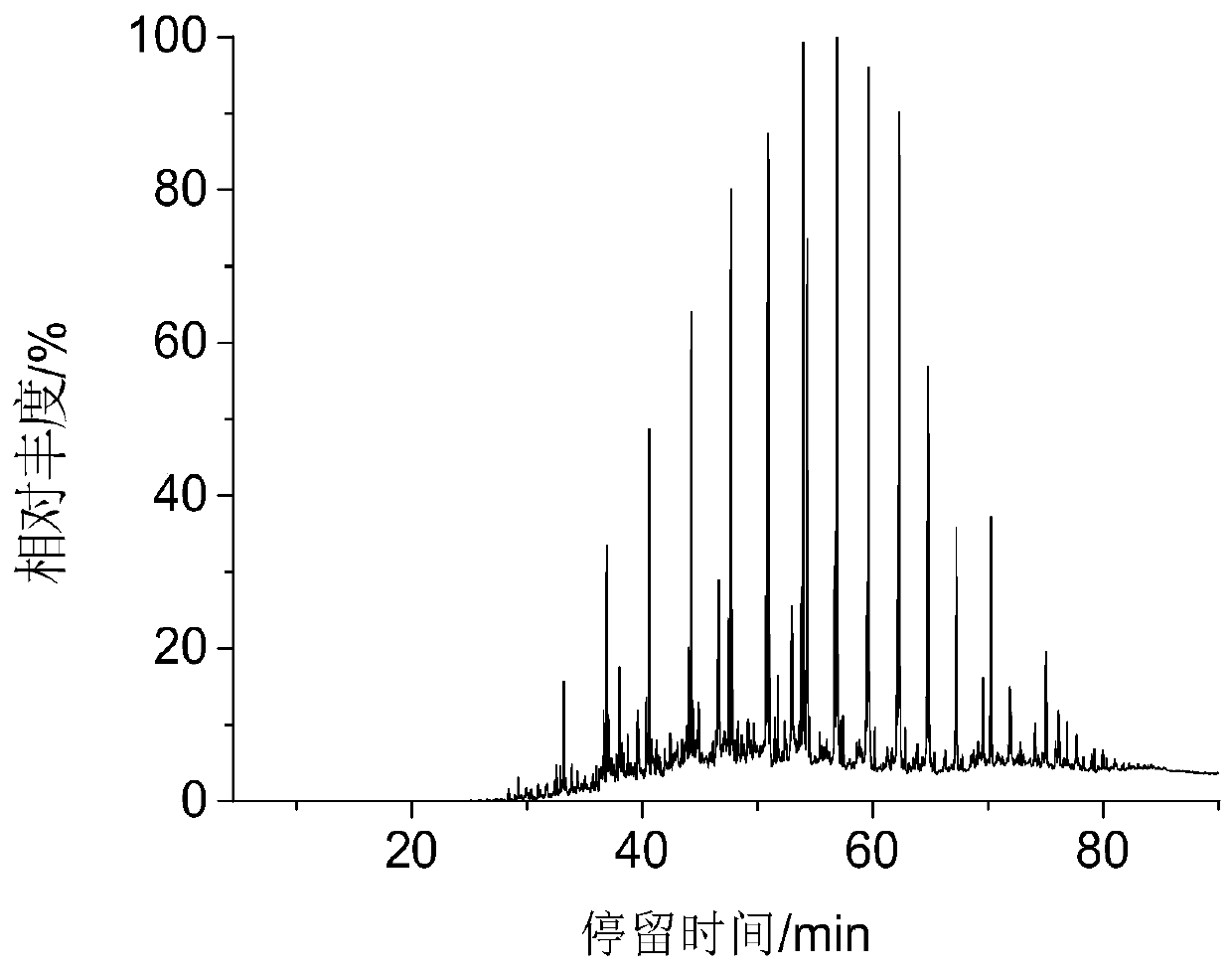

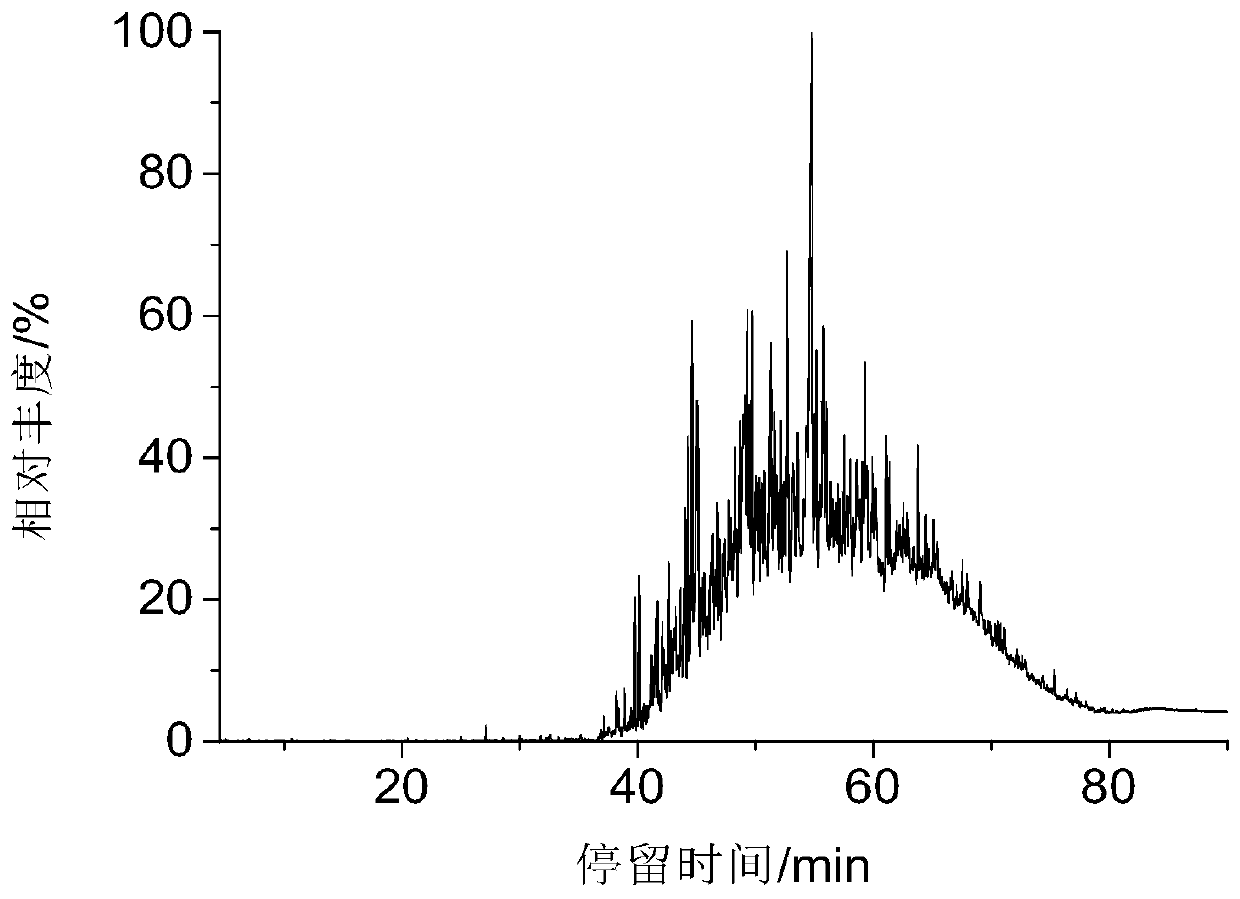

Image

Examples

Embodiment 1

[0067] 1) Weigh 5g of medium-low temperature coal tar heavy oil (sample 2) into a 500mL No. 1 round bottom flask, then add 250mL of n-heptane, heat to reflux for 1-4h, and then let it settle in a dark place for 1-4h.

[0068] 2) The quantitative filter paper is pretreated, specifically: soak the quantitative filter paper with n-heptane and toluene for 12 hours, and dry it for 12 hours for later use.

[0069] Pour the supernatant in the No. 1 round-bottom flask into a funnel equipped with pretreated quantitative filter paper and filter to obtain the filtrate. The residue in the No. 1 round-bottom flask was ultrasonically extracted several times with 80 mL of n-heptane, and then poured Put it into a funnel equipped with pretreated quantitative filter paper to obtain the washing liquid; collect the filtrate and washing liquid in No. 2 round bottom flask. Fold the filter paper with the residue and put it into the Soxhlet extractor, connect the No. 2 round-bottomed flask with the S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com