Preparation method of low-temperature sintering nanosilver paste heat conductivity testing sample

A technology of nano-silver paste and test samples, which is used in the testing of thermal conductivity of thermal interface materials and the preparation of nano-silver thermal conductivity test samples, which can solve the problem of uneven thermal conductivity of materials, high and low production costs of ceramic substrates and thermal test chips and other problems, to achieve the effect of improving mechanical strength and thermal conductivity, reliable test results and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

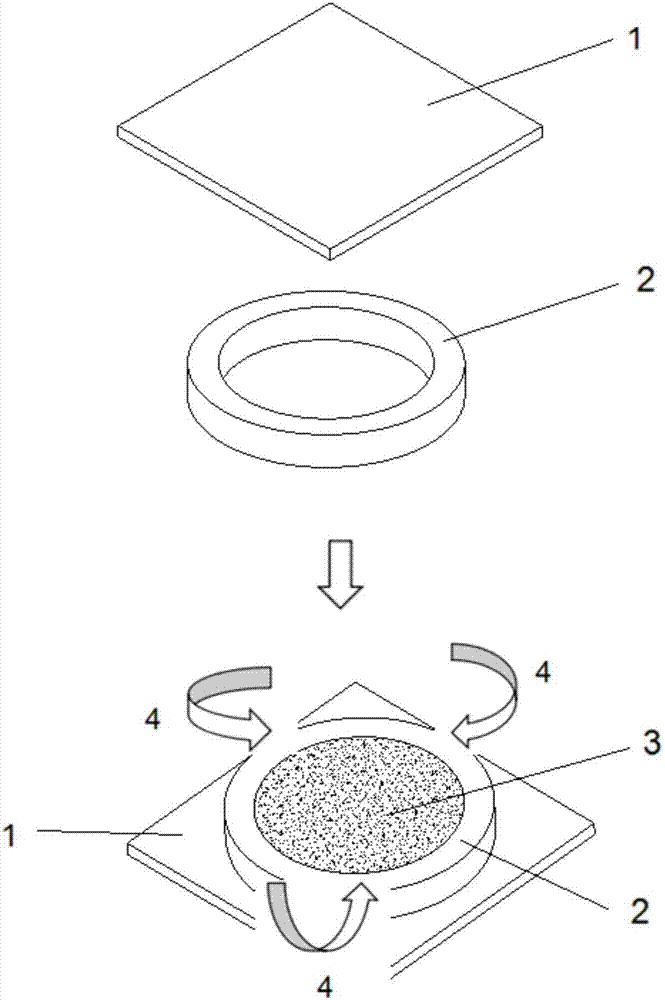

[0026] In this embodiment, see figure 1 with figure 2 , A method for preparing a sample for testing the thermal conductivity of low-temperature sintered nano-silver paste, comprising the following steps:

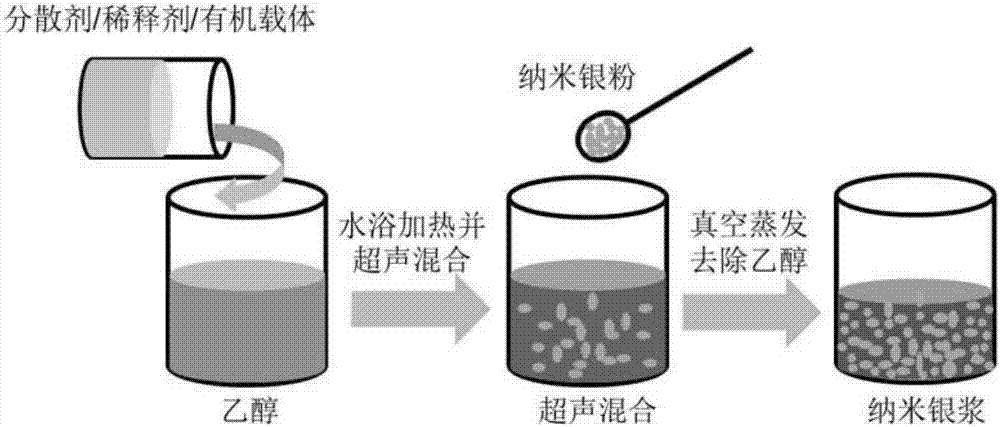

[0027] a. Prepare nano-silver powder by chemical reduction method; add 25ml of ethanol solution into the beaker, add 0.197g of diluent terpineol and 0.025g of dispersant sodium citrate after heating, and then add in water bath heating after fully stirring Organic carrier polyvinyl butyral 0.278g, after cooling to room temperature, add 4.5g of nano silver powder with an average particle size of 20nm, ultrasonic and mechanical stirring the entire mixing system to achieve full mixing, and then use the vacuum evaporation method to remove the organic solvent After the ethanol solution is volatilized, nano-silver paste 3 with a mass fraction of 90% is prepared. The preparation process of nano-silver paste 3 is as follows: figure 2 Shown; this embodiment adopts dispersant, diluent,...

Embodiment 2

[0038] This embodiment is basically the same as the first embodiment, and the special features are:

[0039] In this embodiment, a method for preparing a sample for testing the thermal conductivity of low-temperature sintered nano-silver paste includes the following steps:

[0040] a. Prepare nano-silver powder by chemical reduction method; add 25ml of ethanol solution in the beaker, add 0.197g of diluent terpineol and 0.025g of dispersant sodium citrate after heating, and then add in water bath heating Organic carrier polyvinyl butyral 0.278g, after cooling to room temperature, add 4.5g of nano silver powder with an average particle size of 30nm, ultrasonic and mechanical stirring the whole mixing system to achieve full mixing, and then use the vacuum evaporation method to remove the organic solvent After the ethanol solution is volatilized, nano-silver paste 3 with a mass fraction of 90% is obtained. The preparation process of nano-silver paste 3 is as follows: figure 2 Shown; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com