Inhibitor for copper-interconnection HDI electroplating porefilling and electroplated copper bath

A technology of electroplating hole filling and inhibitors, which is applied in the fields of printed circuit manufacturing, electrical components, printed circuits, etc., can solve the problems of thick copper plating surface deposition thickness, unsuitable for large-scale production, narrow additive operation window, etc. The effect of long life, improved production efficiency, and wide operating window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of inhibitors: First, add 100g of analytically pure sulfuric acid into 2000g of ultrapure water to make about 5% sulfuric acid solution, then add 10g of inhibitors into 1000ml of 5% sulfuric acid solution, stir at 30°C for 10min, and prepare inhibitory agent;

[0021] Accelerator preparation: first add 1g of sodium polydithiodipropane sulfonate to 500g of 5% sulfuric acid solution, and stir at 30°C for 10 minutes; then, add 5% sulfuric acid solution to make the volume to 1L, and continue stirring for 1 hour. Accelerator prepared;

[0022] Preparation of electroplating copper bath: in 2000mL acid copper electroplating solution (containing 220g / L CuSO 4 ·5H 2 O, 55gH 2 SO 4 and 60mg / L Cl - ), add inhibitor 40ml, accelerator 12ml successively, obtain electroplating copper bath after stirring 5min;

[0023] The pretreatment process of electroplating is: plate loading, degreasing, water washing, micro-etching, water washing, copper plating, etc. The corrosi...

Embodiment 2

[0027] Take the blind hole type of 120×75μm (where the hole diameter is 120μm) as an example:

[0028] Adopt the suppressor configuration identical with embodiment 1 and electroplating copper bath configuration,

[0029] Accelerator preparation: Add 1g of sodium alcoholthiopropane sulfonate to 1000g of 5% sulfuric acid solution, stir at 30°C for 15min to prepare the accelerator;

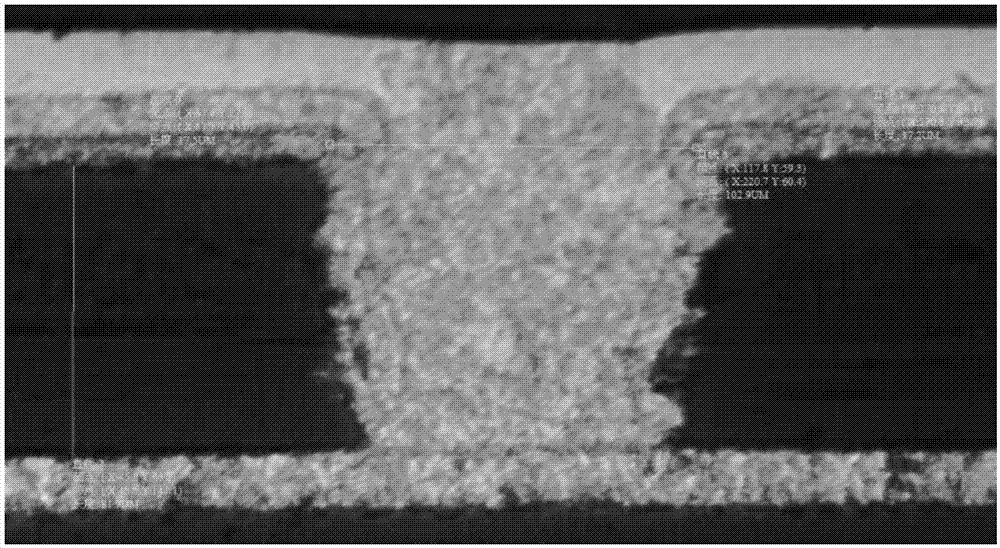

[0030] Control the temperature of the plating tank to 20°C, control the cathode current density to 2ASD, and continue electroplating for 30 minutes. The entire electroplating process is completed under 2.5NL / min pumping. Obtain sample; The metallographic micrograph of the blind hole section of the electroplating filling sample prepared by this embodiment is as follows: figure 2 As shown, the surface copper thickness is 8.9 μm.

Embodiment 3

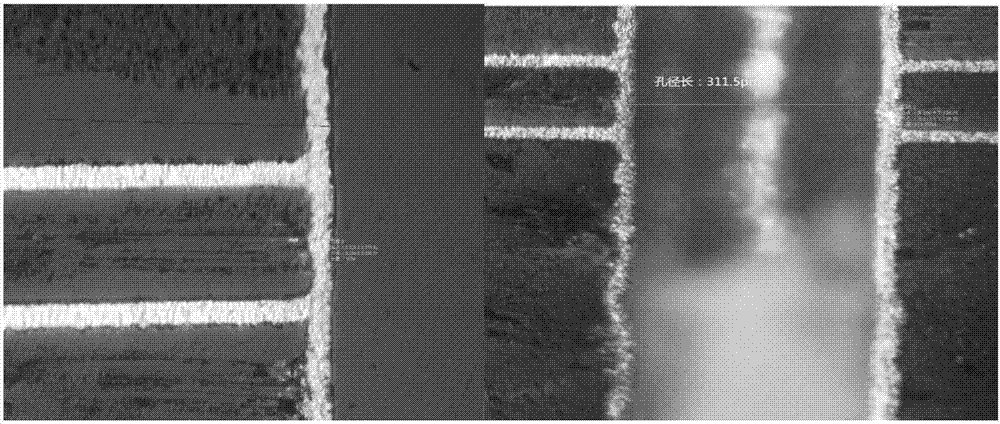

[0032] Taking the 0.3mm×3.0mm (the diameter of the hole is 0.3mm) through-hole as an example, the preparation and experimental conditions of the inhibitor, accelerator and electroplating copper bath are as shown in Example 2, and the electroplated through-hole prepared by this embodiment The metallographic micrograph of the blind hole section of the sample is as follows image 3 As shown; the thickness of the copper at the center point of the through hole is 7.3um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com