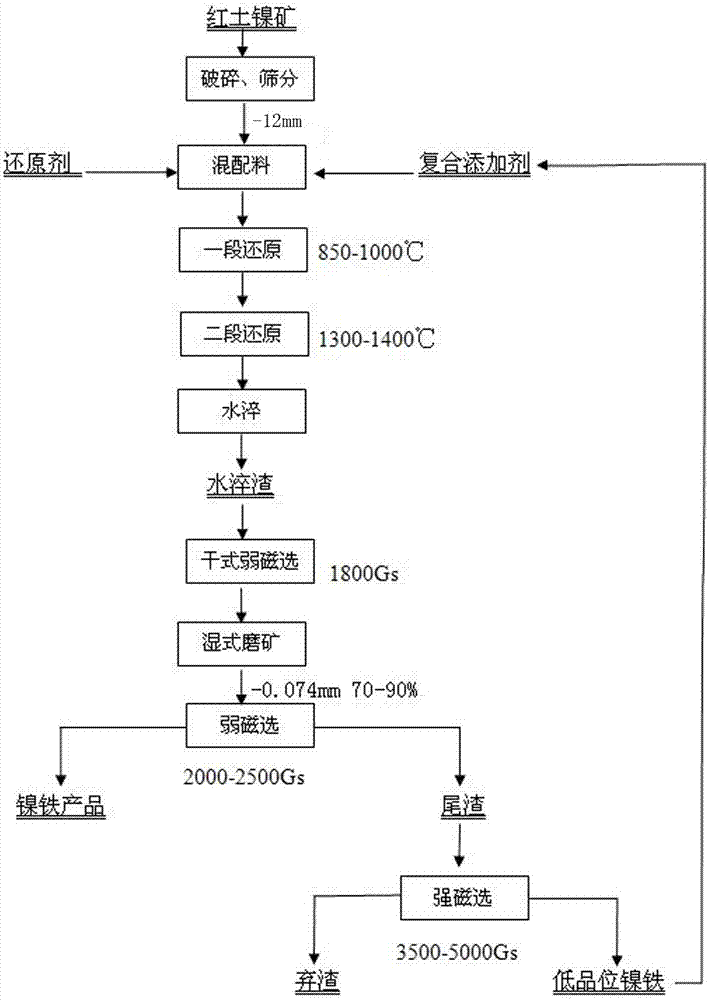

Method for producing ferronickel through nickel-laterite ore direct reduction and ore-dressing enrichment method

A laterite nickel ore and direct technology, applied in the field of direct reduction of laterite nickel ore - beneficiation and enrichment to produce ferronickel, can solve the problems of inability to process laterite nickel ore, fluctuating recovery rate of beneficiation, low recovery rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Laterite nickel ore comes from Indonesia, the main components are: Ni 1.84%, Fe21.52%, MgO13.63%, SiO 2 30.71.

[0029]During the test, the laterite nickel ore was mixed with self-made low-grade nickel-iron composite additives, and two kiln roasting reduction-magnetic separation + strong magnetic magnetic separation technical schemes were used, and good technical indicators were obtained. The main technical conditions of the test: under the condition of 750 ℃, first dry the laterite nickel ore until the surface water content is 20%, and the particle size of the laterite nickel ore is less than 12mm; and iron ore concentrate 3.5%, conventionally mixed and prepared) the addition amount is 15% of the dry base ore, the reducing agent is bituminous coal, and the addition amount is 18% of the dry base ore; the length-to-diameter ratio of the first stage of the rotary kiln 1 is 15: 1. The drying and roasting temperature is 880-920°C and the time is 2 hours to obtain hot calc...

Embodiment 2

[0032] The laterite nickel ore comes from the Tagaung Mountain Nickel Mine in Myanmar, and its main components are: Ni 2.16%, Fe13.98%, MgO 20.32%, SiO2 41.37%. During the test, the laterite nickel ore was mixed with self-made low-grade nickel-iron composite additives, and two kiln roasting reduction-magnetic separation + strong magnetic magnetic separation technical schemes were used, and good technical indicators were obtained. The main technical conditions of the test: under the condition of 700 ℃, first dry the laterite nickel ore until the surface water content is 20%, and the particle size of the laterite nickel ore is less than 12mm; and iron concentrate 3%), the addition amount is 16% of the dry base ore, the reducing agent is bituminous coal, and the addition amount is 16% of the dry base ore; 870-900°C for 2 hours to obtain hot calcined sand. The hot calcined sand in the first section of the rotary kiln 1 is directly fed into the second section of the rotary kiln 2 t...

Embodiment 3

[0035] Laterite nickel ore comes from Philippine nickel ore, the main components are: Ni 1.65%, Fe19.37%, MgO16.11%, SiO 2 38.25%. During the test, the laterite nickel ore was mixed with self-made low-grade nickel-iron composite additives, and two kiln roasting reduction-magnetic separation + strong magnetic magnetic separation technical schemes were used, and good technical indicators were obtained. The main technical conditions of the test: at 730°C, first dry the laterite nickel ore until the surface water content is 18%, and the particle size of the laterite nickel ore is less than 12mm; and iron concentrate 4%), the addition amount is 16% of the dry base ore, the reducing agent is bituminous coal, and the addition amount is 15% of the dry base ore; 860-900°C for 2 hours to obtain hot calcined sand. The hot calcined sand in the first section of the rotary kiln 1 is directly fed into the second section of the rotary kiln 2 through the feeding pipe 4. The feeding pipe 4 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com