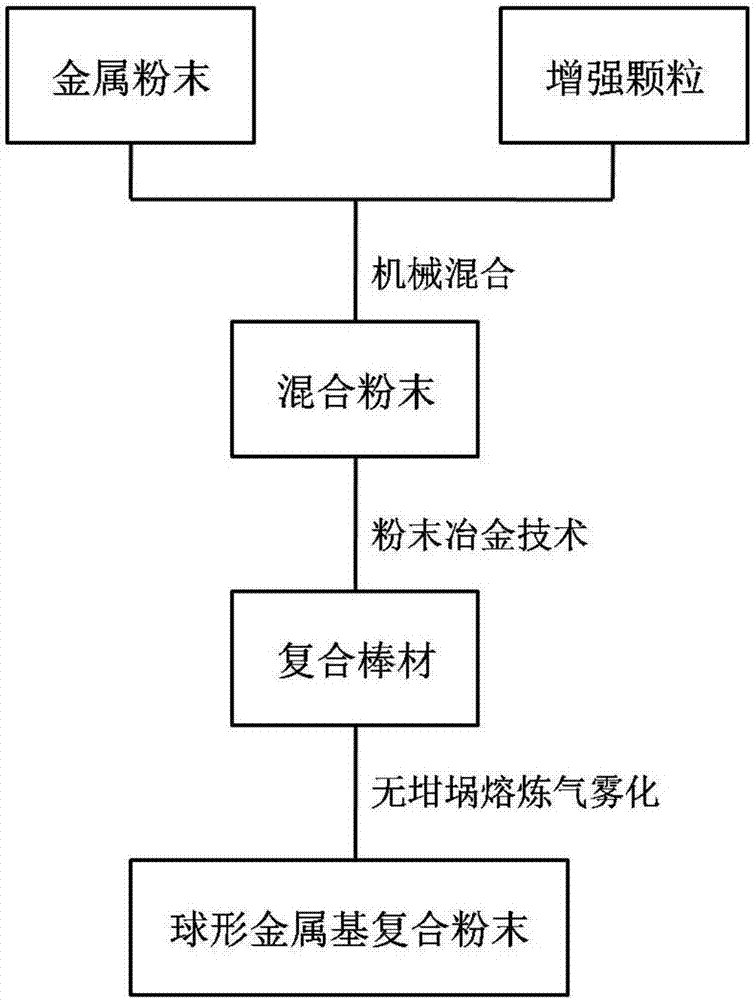

Preparation method for particle reinforced metal-based composite spherical powder material with uniform reinforcing phase distribution

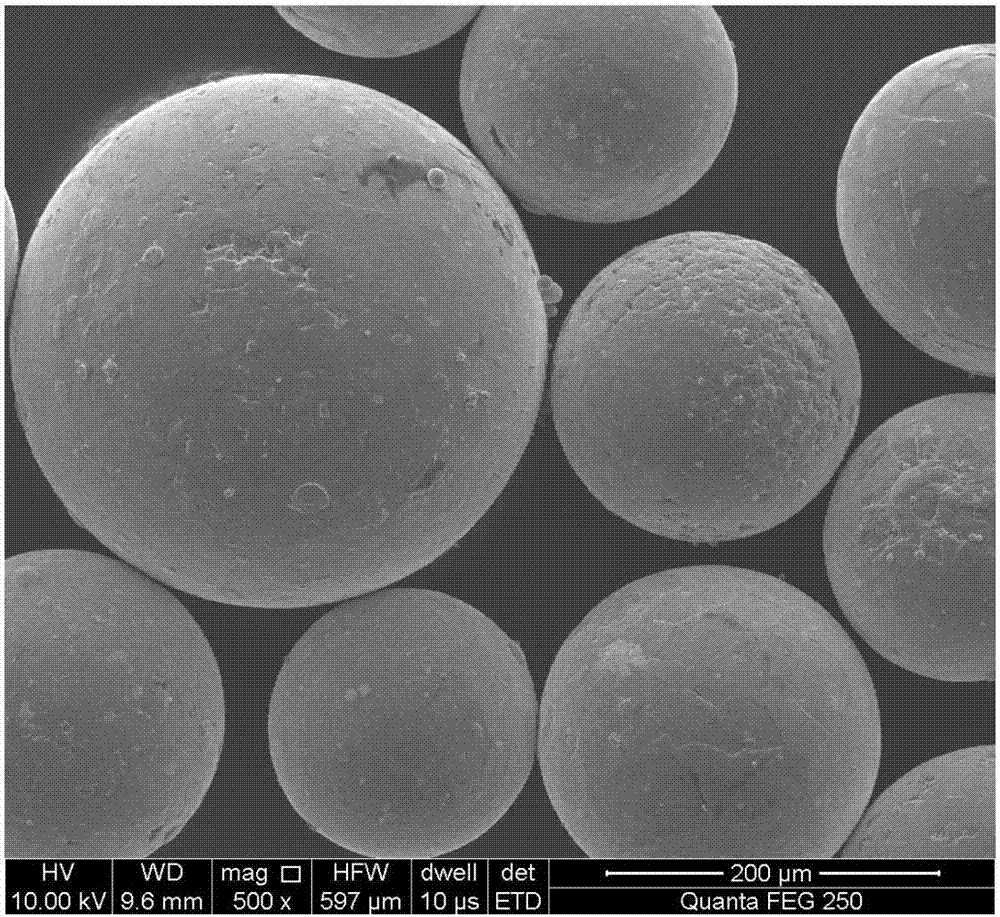

A metal-matrix composite and particle-reinforced technology, applied in the field of powder metallurgy, can solve the problems of difficulty in preparing metal-matrix composite powder with uniform distribution of reinforcement phase, inability to prepare uniform distribution of reinforcement phase, impurity pollution, etc., to avoid powder pollution, high loose packing The effect of density, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Used to prepare titanium alloy composite powder

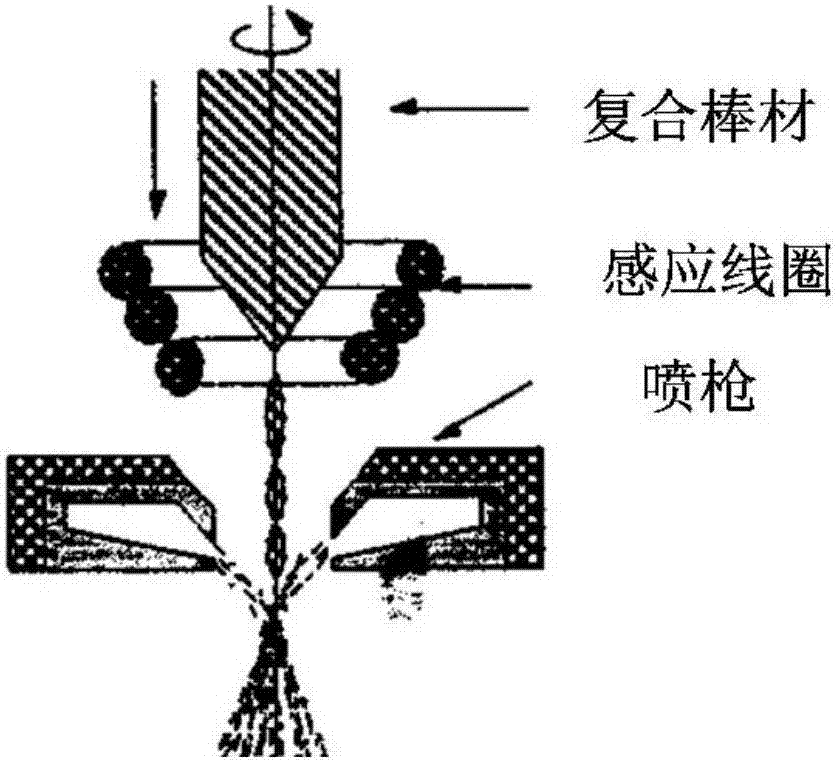

[0035]Gas-atomized Ti6Al4V powder with a particle size of 10 μm to 150 μm and TiC powder with a particle size of 1.5 μm were selected and dosed according to the following mass percentages: 95wt.% Ti6Al4V alloy powder, 5wt.% TiC. Put the powder weighed according to the above formula into a V-shaped mixer. In order to prevent the powder from being oxidized during the mixing process, the mixing tank is sealed and vacuumized, and then filled with argon. The mixing speed is 100rad / min, and the time is 2h. Put the mixed powder into a graphite hot-pressing mold with a diameter of 35mm. To prevent the pollution of carbon in the graphite mold, BN lubricant is coated on the inner wall of the mold. The sintering temperature is 1100°C, the pressure is 16MPa, the holding time is 1h, and the sintering atmosphere is protected by argon. One end of the sintered composite rod is machined to a cone angle of 70°, and the surface is polish...

Embodiment 2

[0037] For the preparation of titanium-based composite powder

[0038] Choose irregular pure Ti powder with a particle size of 10 μm to 60 μm and B with a particle size of 400 nm 4 C powder, according to the following mass percentages: 98wt.% Ti powder, 2wt.% B 4 c. Put the powder weighed according to the above formula into a ball mill jar, the ball-to-material ratio is 1:1, and the material of the grinding balls used is 201 stainless steel. In order to prevent the powder from being oxidized during the mixing process, the ball mill tank was sealed and then evacuated, and then filled with argon. The ball milling speed is 250rad / min, and the ball milling time is 4h. Put the mixed powder into a rubber sheath with a diameter of 50mm, and mold it in a cold isostatic pressing equipment with a molding pressure of 250MPa. The cold isostatic pressed compact was sintered in a vacuum sintering furnace at a sintering temperature of 1400° C. and a holding time of 2 h. One end of the s...

Embodiment 3

[0040] For the preparation of aluminum alloy composite powder

[0041] Gas-atomized AlSi10Mg powder with a particle size of 10 μm to 150 μm and AlN powder with a particle size of 2.0 μm are selected, and the ingredients are prepared according to the following mass percentages: 96wt.% AlSi10Mg alloy powder, 4wt.% AlN. The powder weighed according to the above formula is placed in a ball mill jar, the ball-to-material ratio is 2:1, and the material of the grinding balls used is corundum (Al 2 o 3 ). In order to prevent the powder from being oxidized during the mixing process, the ball mill tank was sealed and then evacuated, and then filled with argon. The low-energy ball milling speed is 150rad / min, and the ball milling time is 1h. Put the mixed powder into a graphite hot-press mold with a diameter of 45mm. The sintering temperature is 610°C, the pressure is 12MPa, the holding time is 1.5h, and the sintering atmosphere is protected by argon. One end of the sintered composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com