Massive solid building waste sorting system based on multiple detection modes

A technology for construction waste and detection methods, applied in sorting and other directions, can solve the problems of difficulty in separating different materials, high cost, large energy, etc., and achieve the effect of saving energy consumption and improving cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

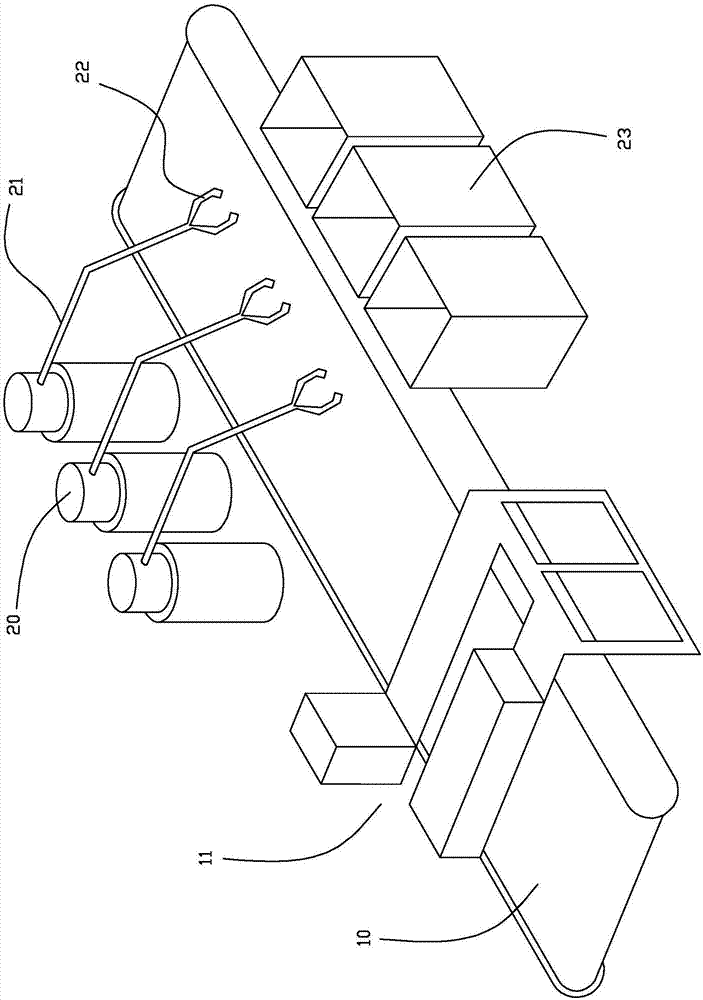

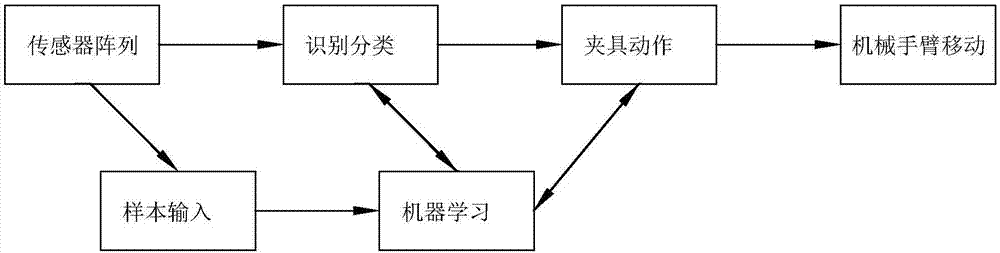

[0028] In order to solve the existing problems in the prior art that require pretreatment before sorting, resulting in increased consumption and low efficiency, the present invention provides a sorting system for massive solid construction waste based on multiple detection methods, such as figure 1 , figure 2 As shown, sensor detection and identification mechanism, control system, industrial robot sorting mechanism;

[0029] The sensor detection and identification mechanism includes a conveyor belt 10 and a sensor array 11 with multiple detection functions; the block-shaped solid construction waste that has been pre-sorted is dispersed and distributed on the conveyor belt 10, and is conveyed through the conveyor belt 10 at a constant speed. In the present invention, the sensor array 11 includes a near-infrared spectrum detection sub-module, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com