In-situ supported denitration sulfur-resistant catalyst compound filter material and preparation method thereof

A composite filter material and catalyst technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problem of weak binding force between catalyst and filter fiber, and difficulty in loading denitrification and anti-sulfur catalysts , catalyst load unevenness and other issues, to achieve high-efficiency denitrification and anti-sulfur performance, improve anti-sulfur activity, and inhibit the effect of vulcanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

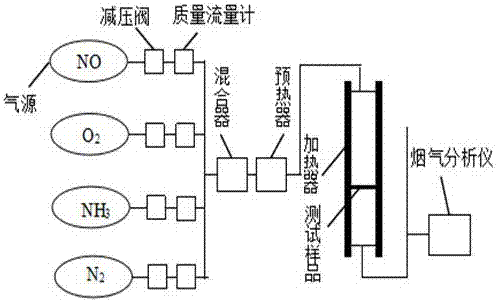

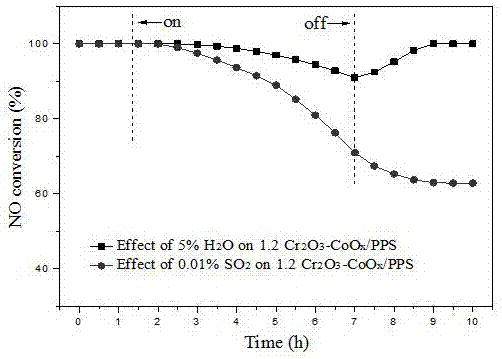

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the composite filter material supporting the denitrification and antisulfur catalyst in situ, the specific steps are:

[0028] 1) Add 0.02g of sodium dodecylbenzenesulfonate into 50mL of deionized water, stir and dissolve to obtain a sodium dodecylbenzenesulfonate solution;

[0029] 2) Weigh a piece of polyphenylene sulfide needle felt with a mass of 0.6g, put it into the solution in step 1), and ultrasonically treat it for 2 hours;

[0030] 3) Add 0.3399gCoCl 2 ·6H 2 O was added to the solution after ultrasonication in step 2), ultrasonicated until the solute was completely dissolved, then stirred at room temperature for 12 hours, so that enough cobalt ions were adsorbed on the surface of PPS;

[0031] 4) Slowly pour 50mL of 0.010mol / L potassium dichromate solution into the solution obtained in step 3), and stir the reaction in a water bath at 80°C for 4.5h until the orange-red color of the solution disappears, which indicates that the react...

Embodiment 2

[0034] The preparation method of the composite filter material supporting the denitrification and antisulfur catalyst in situ, the specific steps are:

[0035] 1) Add 0.02g of sodium dodecylbenzenesulfonate into 50mL of deionized water, stir and dissolve to obtain a sodium dodecylbenzenesulfonate solution;

[0036] 2) Weigh a piece of polyphenylene sulfide needle felt with a mass of 0.6g, put it into the solution in step 1), and ultrasonically treat it for 2 hours;

[0037] 3) Add 0.4249g CoCl 2 ·6H 2 Add O into the solution after ultrasonication in step 2), shake until the solute is completely dissolved, then stir at room temperature for 12 hours, so that enough cobalt ions are adsorbed on the surface of PPS;

[0038] 4) Slowly pour 50mL of 0.012mol / L potassium permanganate solution into the solution obtained in step 2), and stir the reaction in a water bath at 80°C for 4.5h until the orange-red color of the solution disappears, which indicates that the reaction is over, ta...

Embodiment 3

[0041] The preparation method of the composite filter material supporting the denitrification and antisulfur catalyst in situ, the specific steps are:

[0042] 1) Add 0.02g of sodium dodecylbenzenesulfonate into 50mL of deionized water, stir and dissolve to obtain a sodium dodecylbenzenesulfonate solution;

[0043] 2) Weigh a piece of polyphenylene sulfide needle felt with a mass of 0.6g, put it into the solution in step 1), and ultrasonically treat it for 2 hours;

[0044] 3) 0.5098g CoCl 2 ·6H 2 Add O into the solution after ultrasonication in step 2), shake until the solute is completely dissolved, then stir at room temperature for 12 hours, so that enough cobalt ions are adsorbed on the surface of PPS;

[0045] 4) Slowly pour 50mL of 0.014mol / L potassium permanganate solution into the solution obtained in step 2), and stir the reaction in a water bath at 80°C for 4.5h until the orange-red color of the solution disappears, which indicates that the reaction is over, take o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com