A system and method for in-situ degradation of dioxin-like substances in flue gas

A dioxin and flue gas technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of low nitrogen oxide emission concentration and lack of application basis, and achieve high-efficiency low-temperature in-situ degradation, source The effect of broad, promising industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

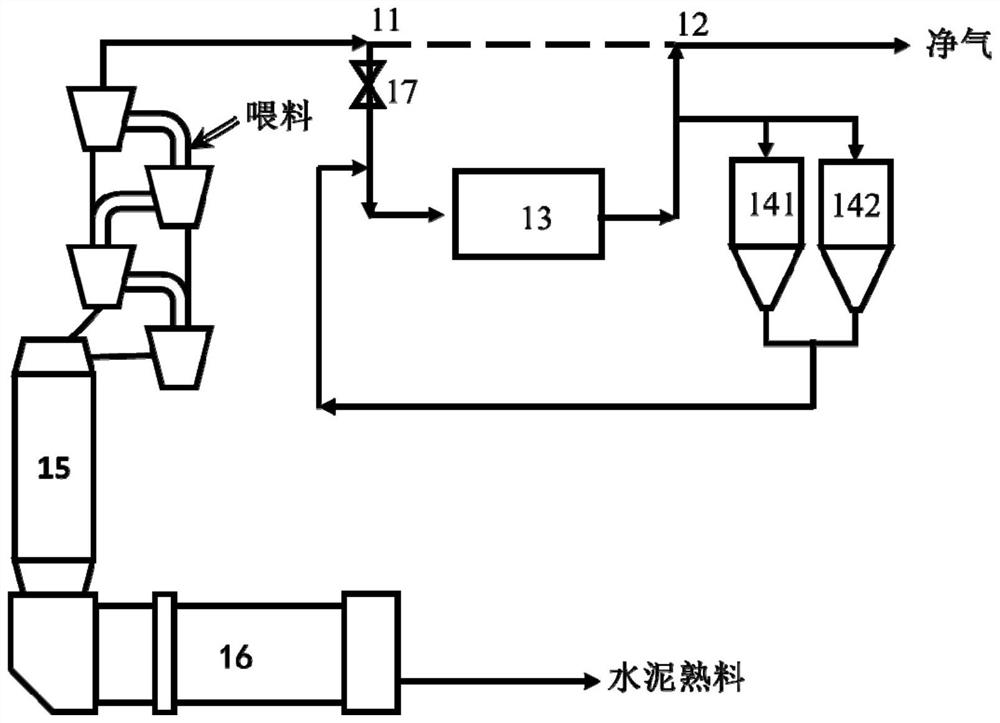

[0045] This embodiment provides a system and method for carbon-based catalysts to degrade dioxins in cement kiln flue gas, such as figure 1 As shown, the system includes a purification pipeline, a degradation system 13 and a catalyst circulation system.

[0046] The cement kiln includes a calciner 15 and a cement rotary kiln 16. The purification pipeline is arranged between the flue gas outlet 11 and the clean gas inlet 12. The flue gas is introduced into the degradation system 13 of dioxins. After the degradation process of dioxins is completed, the flue gas returns to the flue gas discharge main pipeline from the clean gas inlet 12 and enters the raw meal mill.

[0047] The catalyst circulation system includes a catalyst injection pipeline, a catalyst interception recovery pipeline, a catalyst storage tank 141 and a catalyst storage tank 142 .

[0048] The catalyst inlet of the catalyst circulation system is at the initial position of the air intake of the dioxin-like subst...

Embodiment 2

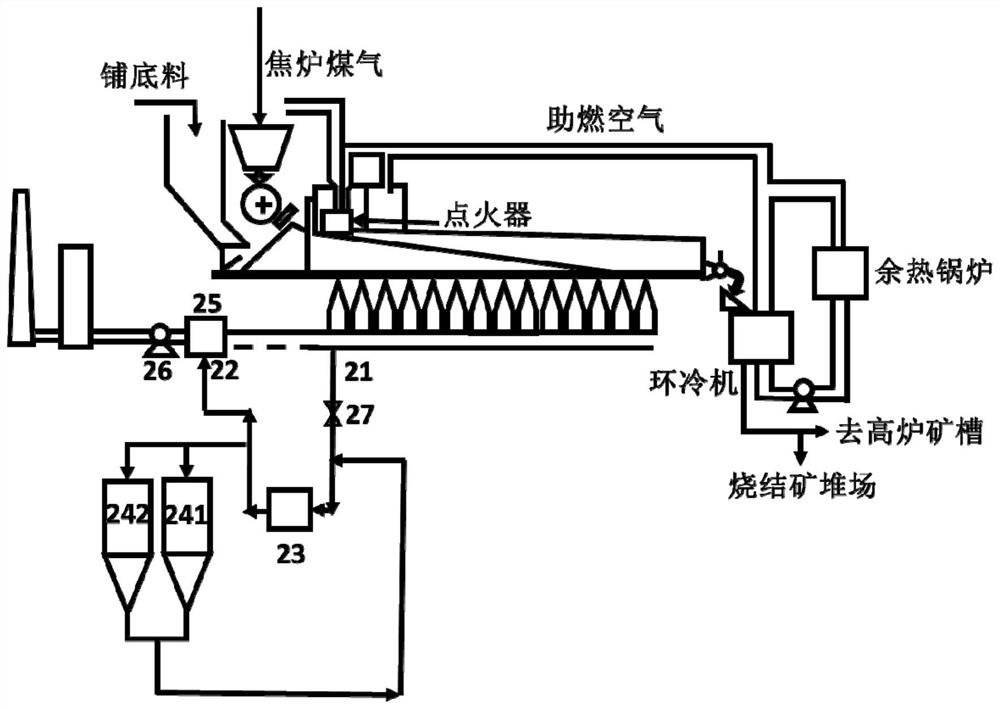

[0056] This embodiment provides a system and method for carbon-based catalysts to degrade dioxin-like substances in the flue gas of the sintering process in the iron and steel industry, such as figure 2 As shown, the system includes a purification pipeline, a degradation system 23 and a catalyst circulation system.

[0057] In the flue gas discharge pipeline of the sintering process in the iron and steel industry, a purification pipeline is selected between the flue gas outlet 21 and the clean gas inlet 22, and the flue gas is introduced into dioxins from the flue gas outlet 21 with a flue gas temperature of 600°C. Degradation system 23, after the flue gas completes the degradation process of dioxin, it returns to the flue gas discharge main pipeline from the clean gas inlet 22, enters the dust collector 25, and is discharged by the main exhaust fan 26.

[0058] The catalyst circulation system includes a catalyst injection pipeline, a catalyst interception recovery pipeline, ...

Embodiment 3

[0067] The difference with Example 1 is that the catalyst is replaced by cerium-loaded activated carbon AC-Ce, including CeO with a mass ratio of 30:100 2 and carbon materials; the temperature at the flue gas outlet 11 is 550°C; the temperature of the degradation reaction is 400°C, and the cooling rate is 300°C / s.

[0068] The degradation efficiency was 93.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com