Antistatic safety shoes

A kind of labor protection shoes, anti-static technology, applied in the direction of electrotherapy, treatment, etc., can solve the problems of inconvenient wearing and taking off, many materials, increase the cost of anti-static shoes, etc., to save the cost of shoemaking and the effect of wearing comfortable shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

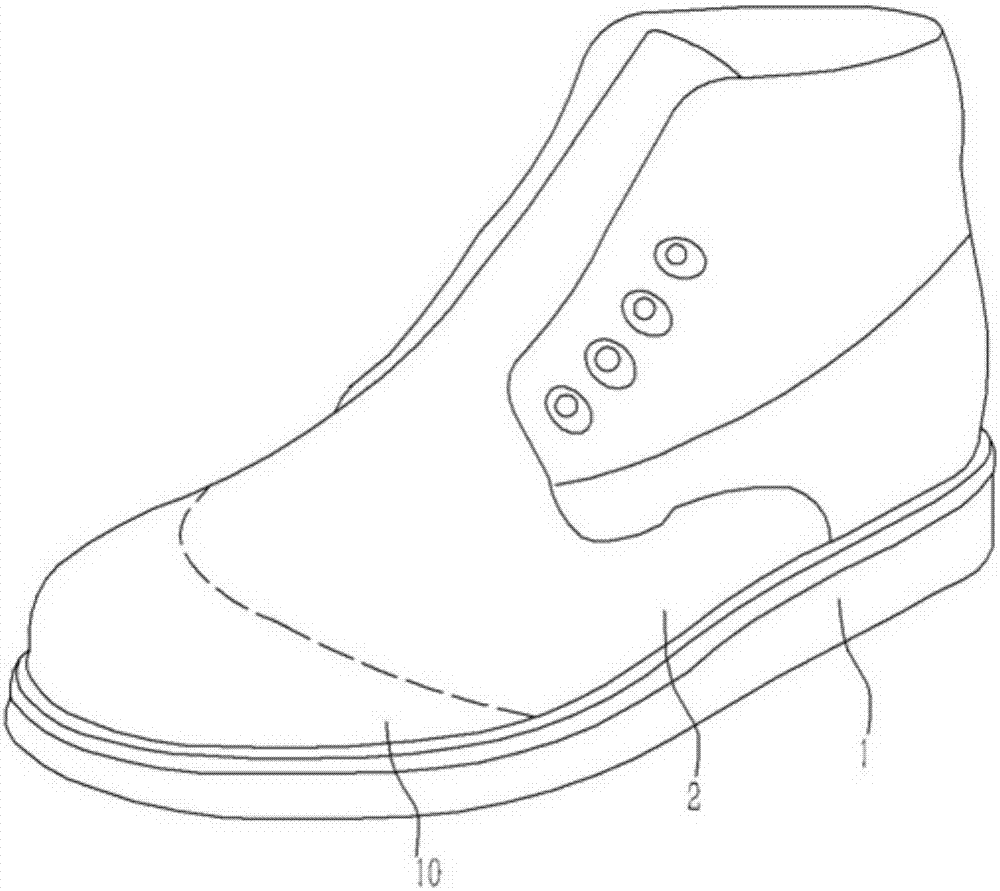

[0019] Example: see Figures 1 to 3 As shown, an anti-static safety shoe includes a sole 1 and a vamp 2, a strip-shaped insulating gasket 3 is embedded in the sole 1, and an insert penetrating through the bottom surface of the sole 1 is formed in the sole 1 directly below the insulating gasket 3. A hole 11, a counterbore 12 penetrating through the upper bottom surface of the sole 1 is formed in the sole 1 directly above the insulating spacer 3, and a cylindrical conductive rubber block 4 is inserted and fixed in the jack 11 of the sole 1, and the upper surface of the conductive rubber block 4 A stepped hole 41 is formed on the end face, and the stepped hole 41 is composed of a large hole at the upper end and a small hole at the lower end. The first permanent magnet ring 6 is inserted into the large hole of the stepped hole 41, and the small hole of the stepped hole 41 is inserted with a Vertical conductive column 5, the upper end of the conductive column 5 is inserted into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com