Electron beam floating zone melting directional solidification preparation method for Fe-Al-Ta composite material

A technology for smelting and composite materials in a suspended area, applied in the field of metallurgy, can solve problems such as restricting structure control and performance improvement, hindering the large-scale application of high-temperature structural materials, and unable to further refine the solidified structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0050] 1) Prepare Fe85 / Ta7 / Al8 (at%) eutectic alloy according to the eutectic point of the Fe-Al-Ta phase diagram. Smelted in a vacuum induction furnace with a high-purity Ar atmosphere, and wire-cut into Test stick.

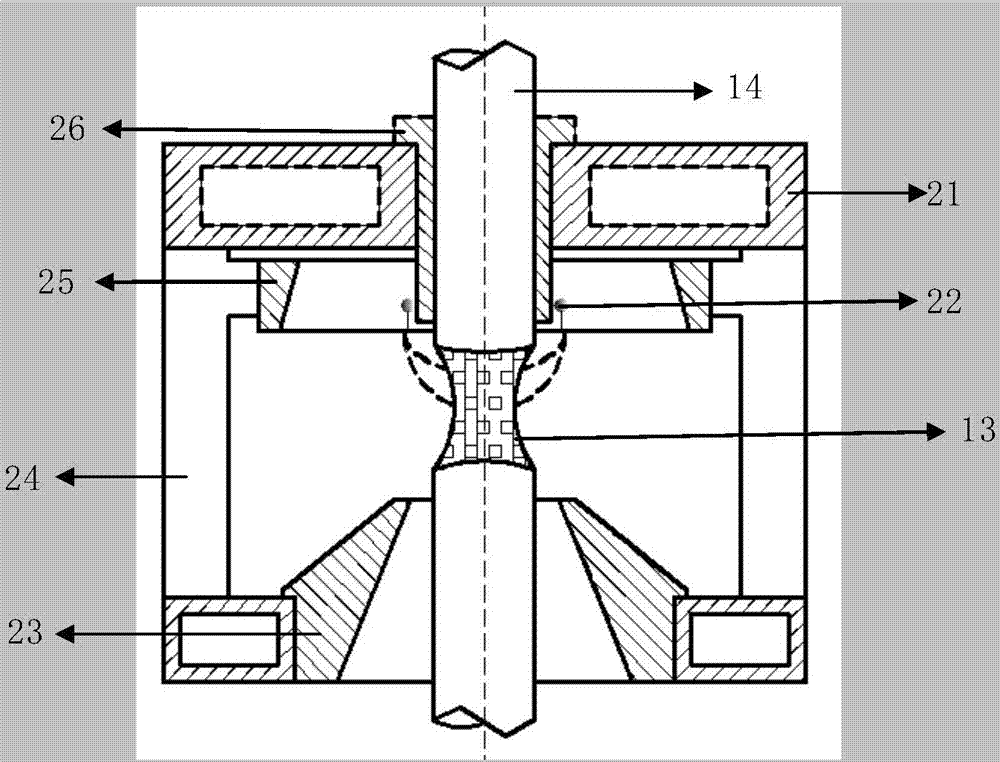

[0051] 2) Cut into Test bar, in the vacuum degree of 1.4~1.6×10 -4 mbar, conduction ratio of 30%, acceleration voltage of 8.7KV, emission current of 11mA in a furnace with electron beam area melting (1600°C) to melt the test bar area. (Using a ring electron gun to melt the test bar and form a narrow melting zone on it. The melting zone is maintained between the original material bar and the solidified material bar by surface tension. When the test bar moves slowly in the vertical direction, it solidifies directionally behind the melting zone. , So as to grow along the vertical direction of the entire rod.)

[0052] 3) The sample melts in a small range, through bottom-up directional solidification, the temperature gradient of the solid-liquid interface is controlle...

Embodiment example 2

[0054] 1) Prepare Fe85 / Ta7 / Al8 (at%) eutectic alloy according to the eutectic point of the Fe-Al-Ta phase diagram. Smelted in a vacuum induction furnace with a high-purity Ar atmosphere, and wire-cut into Test stick.

[0055] 2) Cut into Test bar, in the vacuum degree of 1.4~1.6×10 -4 mbar, conduction ratio of 30%, acceleration voltage of 8.7KV, emission current of 11mA in a furnace with electron beam area melting (1600°C) to melt the test bar area.

[0056] 3) The sample melts in a small range, through bottom-up directional solidification, the temperature gradient of the solid-liquid interface is controlled at 390K / cm, and the solidification rate of the test bar is 1mm / min for directional solidification to optimize eutectic Alloy structure and improve its performance.

Embodiment example 3

[0058] 1) Prepare Fe85 / Ta7 / Al8 (at%) eutectic alloy according to the eutectic point of the Fe-Al-Ta phase diagram. Smelted in a vacuum induction furnace with a high-purity Ar atmosphere, and wire-cut into Test stick.

[0059] 2) Cut into Test bar, in the vacuum degree of 1.4~1.6×10 -4 mbar, conduction ratio of 30%, acceleration voltage of 8.7KV, emission current of 11mA in a furnace with electron beam area melting (1600°C) to melt the test bar area.

[0060] 3) The sample melts in a small range, through bottom-up directional solidification, the temperature gradient of the solid-liquid interface is controlled at 410K / cm, and the solidification rate of the test bar is 2mm / min for directional solidification to optimize eutectic Alloy structure and improve its performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com