Bacteria and its application in absorbing VOCs

A technology of bacteria and fungi, applied in the field of VOCs treatment, can solve the problem of low waste gas treatment efficiency, achieve high degradation efficiency and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of described synthetic adsorbent comprises the following steps:

[0031] (a) analyzing the element content in the blast furnace slag by X-ray fluorescence spectrometry, and calculating the ratio of Mg / (Mn+Si) to 0.05-0.09 and the ratio of Mn / (Mn+Si) to 0.187-0.213 through the element content;

[0032] (b) Adjust blast furnace slag Mg / (Mn+Si) ratio and Mn / (Mn+Si) ratio, add MgO and SiO to 1g blast furnace slag 2 Adjust the Mg / (Mn+Si) ratio and the Mn / (Mn+Si) ratio to 0.83-0.85 and 0.142-0.148 respectively to prepare a mixture A;

[0033] (c) Add 32-35mL deionized water to the mixture A prepared in step b, and stir for 12-15min at a microwave power of 100-150W, a temperature of 30-35°C, and a rotation speed of 200-300r / min to obtain mixture B;

[0034] (d) Put the mixture B prepared in step c in a reaction kettle, react at 400-500°C for 4-6h to obtain a reaction product, wash the reaction product with deionized water, and dry it at 75-82°C until i...

Embodiment 1

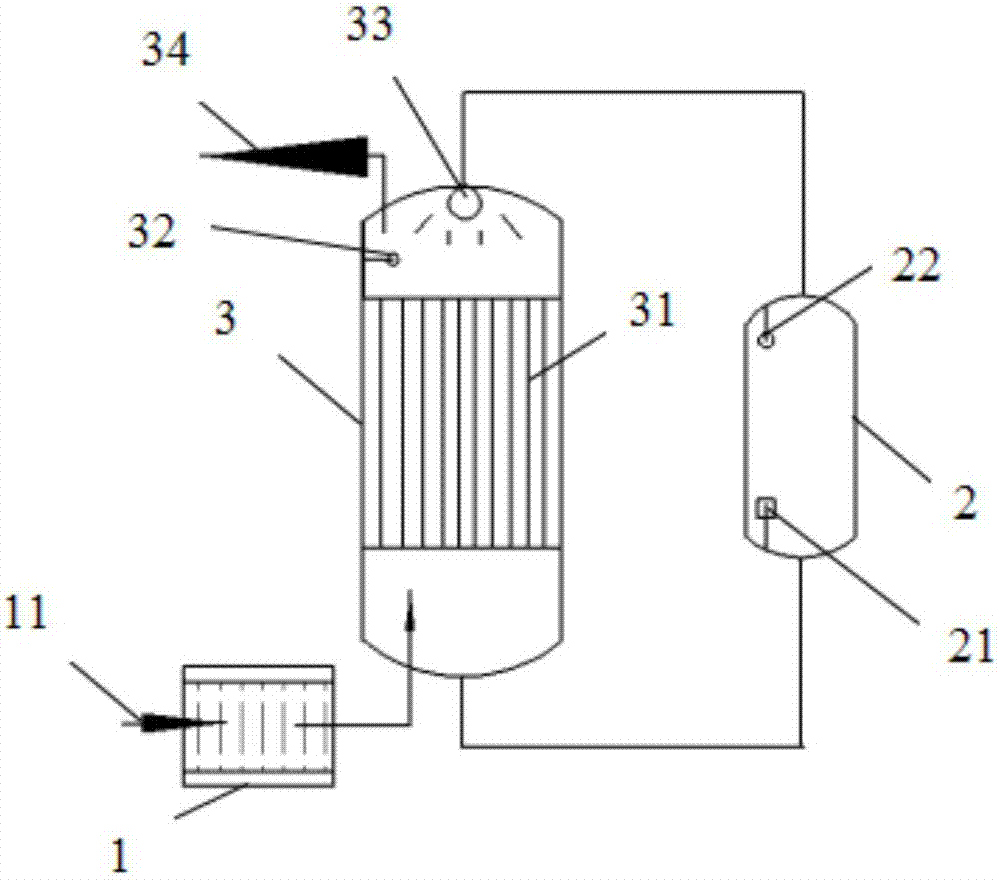

[0043] Such as figure 1 Shown: a reaction system for absorbing VOCS, including an ultraviolet light treatment chamber 1, a circulating liquid device 2, and an absorption reaction tower 3. The ultraviolet light treatment chamber 1 is connected to the absorption reaction tower 3 through a pipeline A, and the circulation The liquid device 2 is connected to the top of the absorption reaction tower 3 through a pipe B, and the circulating liquid device 2 is connected to the bottom of the absorption reaction tower 3 through a pipe C.

[0044] The ultraviolet light treatment chamber 1 includes an air inlet 11 .

[0045] The circulating fluid device 2 includes a temperature sensor A 21 and a pH electrode 22 , the temperature sensor A 21 is arranged on the top of the circulating fluid device 2 , and the pH electrode 22 is arranged on the bottom of the circulating fluid device 2 .

[0046] The absorption reaction tower 3 includes a grid-type biofilm filler 31, a temperature sensor B 32,...

Embodiment 2

[0061] Such as figure 1 Shown: a reaction system for absorbing VOCS, including an ultraviolet light treatment chamber 1, a circulating liquid device 2, and an absorption reaction tower 3. The ultraviolet light treatment chamber 1 is connected to the absorption reaction tower 3 through a pipeline A, and the circulation The liquid device 2 is connected to the top of the absorption reaction tower 3 through a pipe B, and the circulating liquid device 2 is connected to the bottom of the absorption reaction tower 3 through a pipe C.

[0062] The ultraviolet light treatment chamber 1 includes an air inlet 11 .

[0063] The circulating fluid device 2 includes a temperature sensor A 21 and a pH electrode 22 , the temperature sensor A 21 is arranged on the top of the circulating fluid device 2 , and the pH electrode 22 is arranged on the bottom of the circulating fluid device 2 .

[0064] The absorption reaction tower 3 includes a grid-type biofilm filler 31, a temperature sensor B 32,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com