A kind of preparation method of molten steel cleaning agent

A purification agent and molten steel technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problem of not promoting the growth, floating and removal of inclusions, and not reducing the melting point of fine inclusions in steel, which is unfavorable for steel products Quality and other issues, to achieve the effect of improving purification effect, promoting removal and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The cleaning agent of this embodiment is granular, and the cleaning agent is spherical granular, and the particle diameter is 5 ~ 10mm; ): 1, the preferred 8:1 of the present embodiment, the effective components include aluminum metal, lime powder, silicon carbide powder, titanium dioxide and biomass, the effective components are as follows in parts by mass: 50-70 parts of metal aluminum, 20-70 parts of lime powder 40 parts, 5-20 parts of titanium dioxide, 5-15 parts of silicon carbide powder, 2-4 parts of biomass, selected in this embodiment: 60 kg of aluminum metal, 30 kg of lime powder, 18 kg of titanium dioxide, 15 kg of silicon carbide powder, and 3 kg of biomass.

[0042]It is worth noting that each component in the effective components is in powder form, and the particle size is ≤0.1mm, that is, metal aluminum, lime powder, titanium dioxide, and silicon carbide powder are in powder form, and metal aluminum, lime powder, titanium dioxide, raw The particle size of ...

Embodiment 2

[0067] The basic content of this embodiment is the same as that of Example 1, except that the cleaning agent is in the form of granules, the cleaning agent is in the form of spherical particles, and the diameter of the particles is 5-10mm; the cleaning agent includes effective components and bonding components, and the effective components The mass ratio to the adhesive component is (5-10):1, preferably 5:1 in this embodiment.

[0068] The effective components in the purification agent of this embodiment also include graphite powder, red jade soil and magnesium-manganese alloy; the effective components are composed according to the following mass parts, 50-70 parts of metal aluminum, 20-40 parts of lime powder, and 0-30 parts of graphite powder part, 5-20 parts of titanium dioxide, 5-15 parts of silicon carbide powder, 2-4 parts of biomass, 0-1 part of red jade soil, 0-2 part of magnesium-manganese alloy; the present embodiment is 50 kg of metal aluminum, 20 kg of lime powder, ...

Embodiment 3

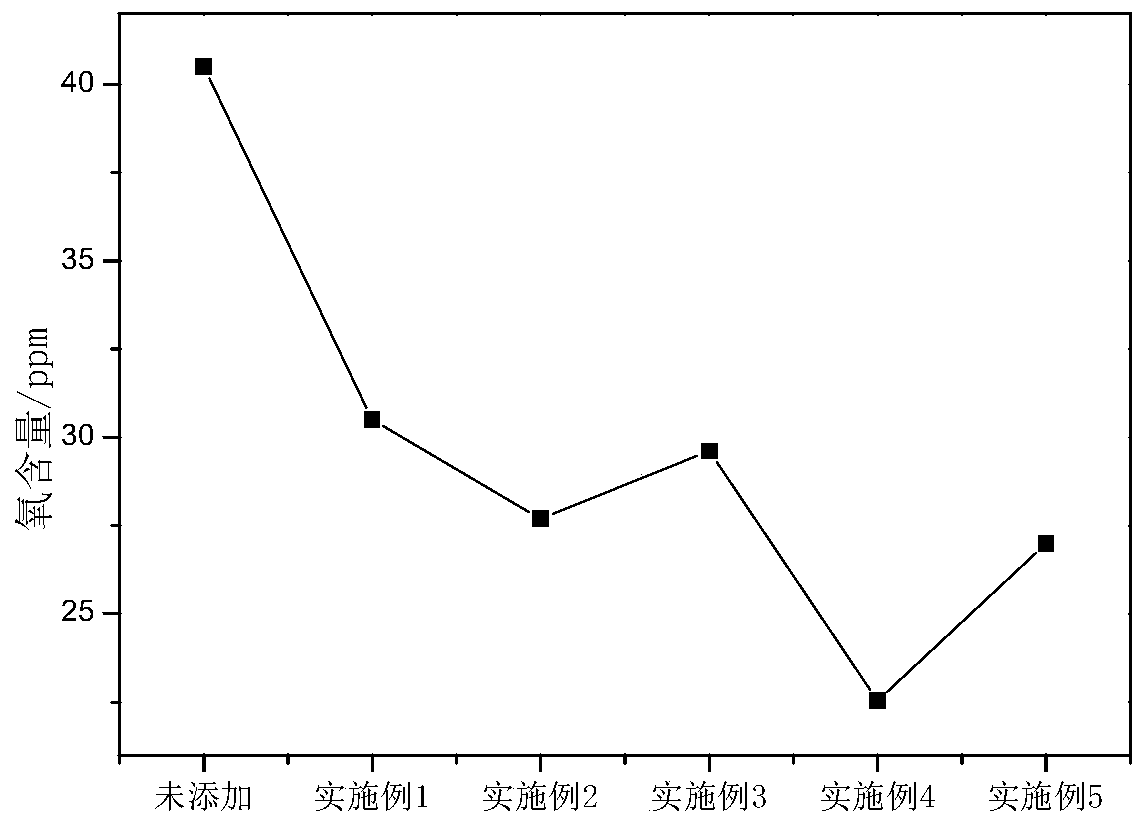

[0079] The basic content of this embodiment is the same as that of Example 1, except that the adhesive component of the purifying agent also includes starch and kaolin, and the adhesive component is composed of the following parts by mass: 60-80 parts of kaolin, 20-40 parts of sulfonated phenolic resin parts, starch 0-10 parts, oil sands 0-5 parts. This embodiment is composed according to the following mass: 80 kg of kaolin, 40 kg of sulfonated phenolic resin, 5 kg of starch, and 2 kg of oil sand. Detect the total oxygen content in molten steel after modification, and record as shown in Table 1, the data change is as follows figure 1 As shown, the mass ratio of the effective component to the binding component is 6:1, and the mixture is completed to obtain the cleaning agent mixture.

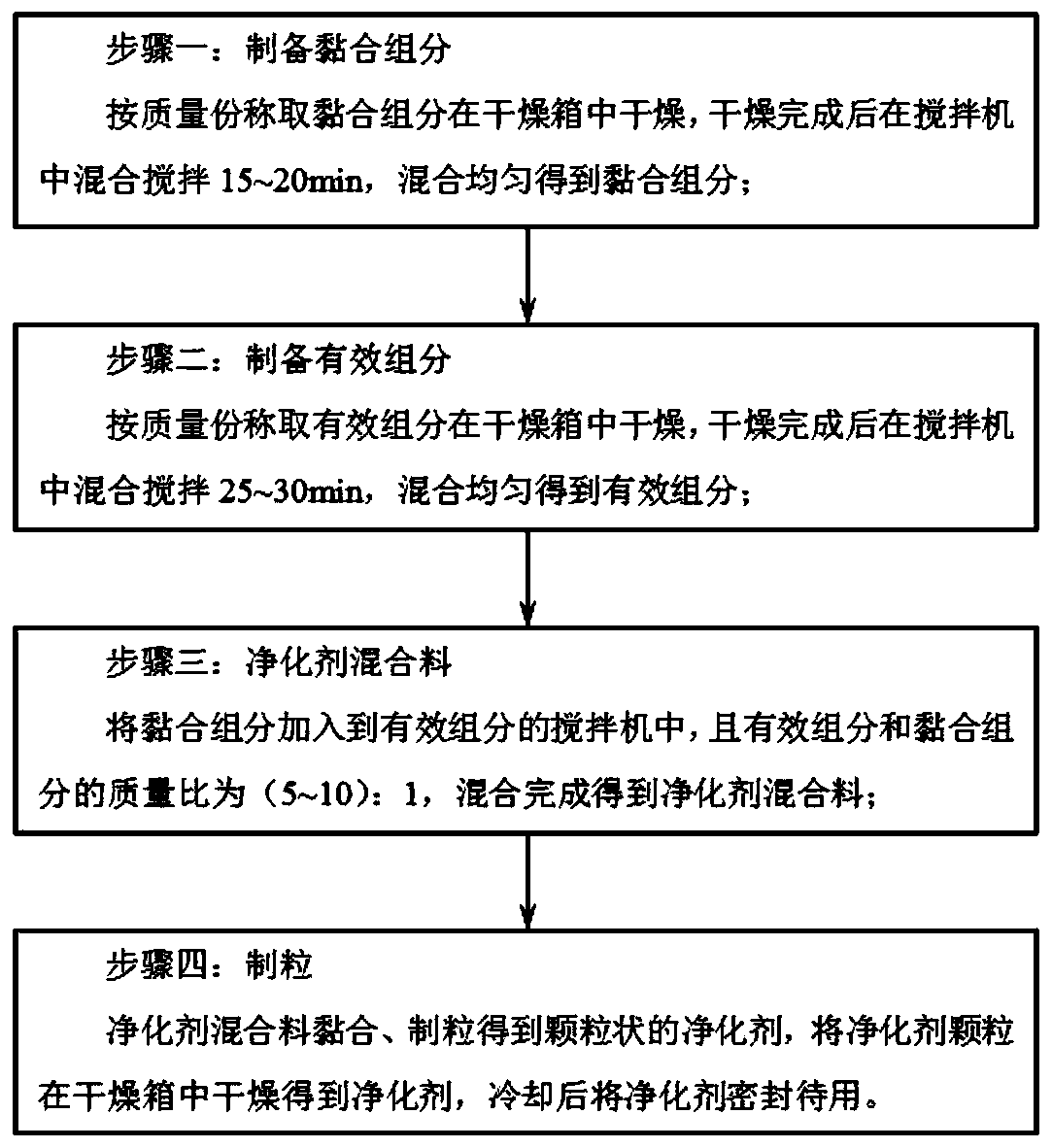

[0080] A kind of preparation method of molten steel cleaning agent of the present embodiment, concrete steps are as follows:

[0081] Step 1: Preparation of Adhesive Components

[0082] Weigh ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com