A composite high temperature piezoelectric ceramic material

A ceramic material, high-temperature piezoelectric technology, applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problem of low piezoelectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] BiFeO 3 The preparation of ceramic powder can refer to 【G.L.Yuan, S.W.Or, Y.P.Wang, Z.G.Liu, and J.M.Liu, Solid State Commun.138, 76(2006).】

[0026] In this example, Bi 2 o 3 , Fe 2 o 3 Powder preparation of BiFeO 3 ceramics. Ball milled in a ball mill with a rotating speed of 300r / min for 8 hours and dried to obtain BiFeO with more than 80% particles of micron diameter 3 Ceramic powder.

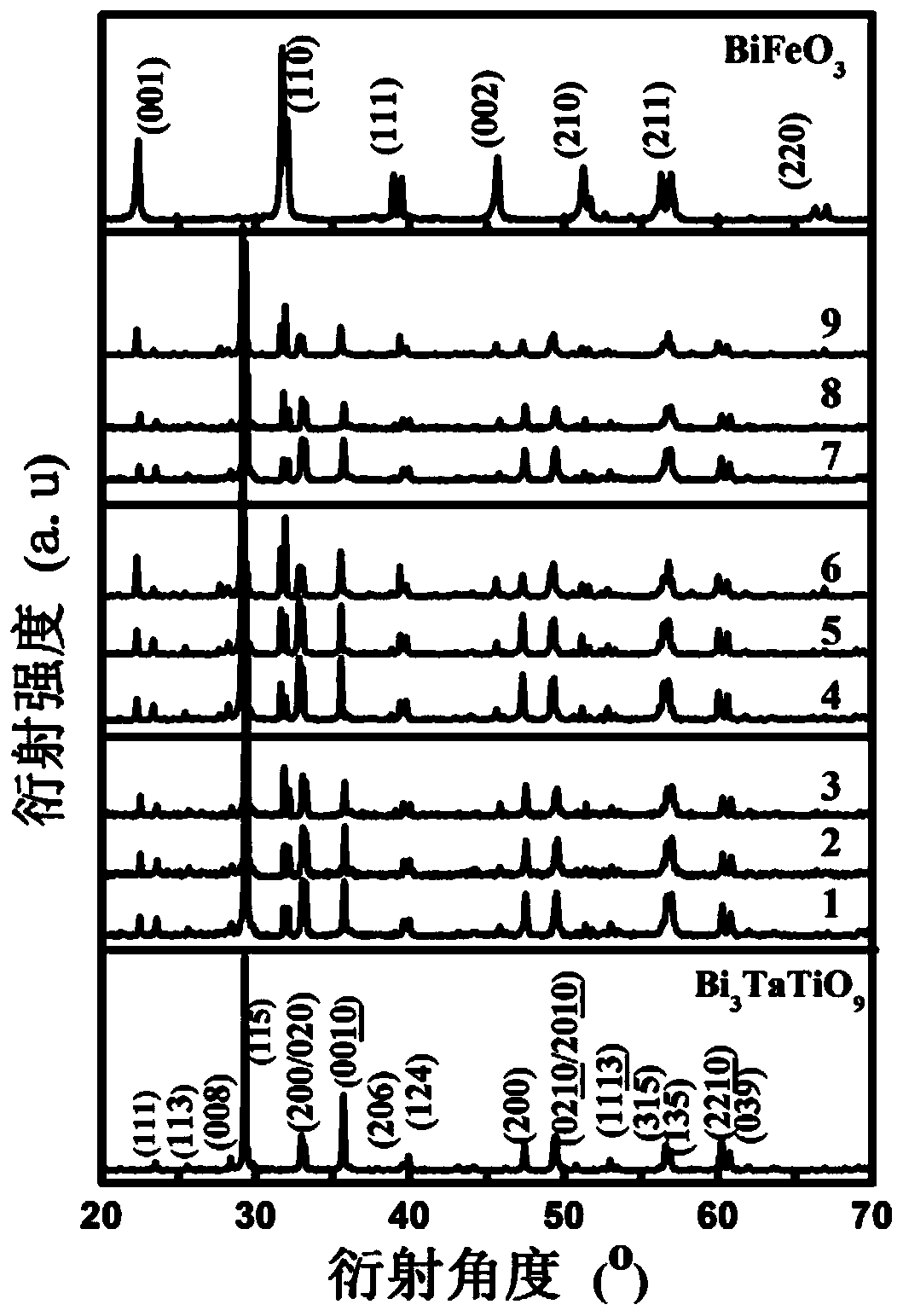

[0027] The BiFeO prepared by the present embodiment is analyzed by X-ray diffractometer 3 Ceramic samples were analyzed. The result is as figure 1 shown, indicating that BiFeO 3 The ceramic crystallizes well.

Embodiment 2

[0029] Bi 3 TaTiO 9 The preparation of ceramic powder can refer to [Y.Noguchi, R.Satoh, M.Miyayama, K.Tetsuichi, J.Ceram.Soc.Jpn.109,29(2001)]

[0030] In this example, Ta 2 o 5 、 Bi 2 o 3 、TiO 2 Powder preparation Bi 3 TaTiO 9 ceramics. Ball milled in a ball mill with a rotating speed of 300r / min for 4 hours and dried to obtain Bi with more than 80% particles of nanometer diameter 3 TaTiO 9 Ceramic powder. Brush the upper and lower surfaces of the fired ceramic samples with silver electrodes, place them in methyl silicone oil, and apply a high-voltage electric field for polarization. The polarization electric field is 150kV / cm, and the polarization time is 30 minutes.

[0031] With X-ray diffractometer to the Bi that present embodiment makes 3 TaTiO 9 Ceramic samples were analyzed. The result is as figure 1 It shows that the ceramic crystallization is good.

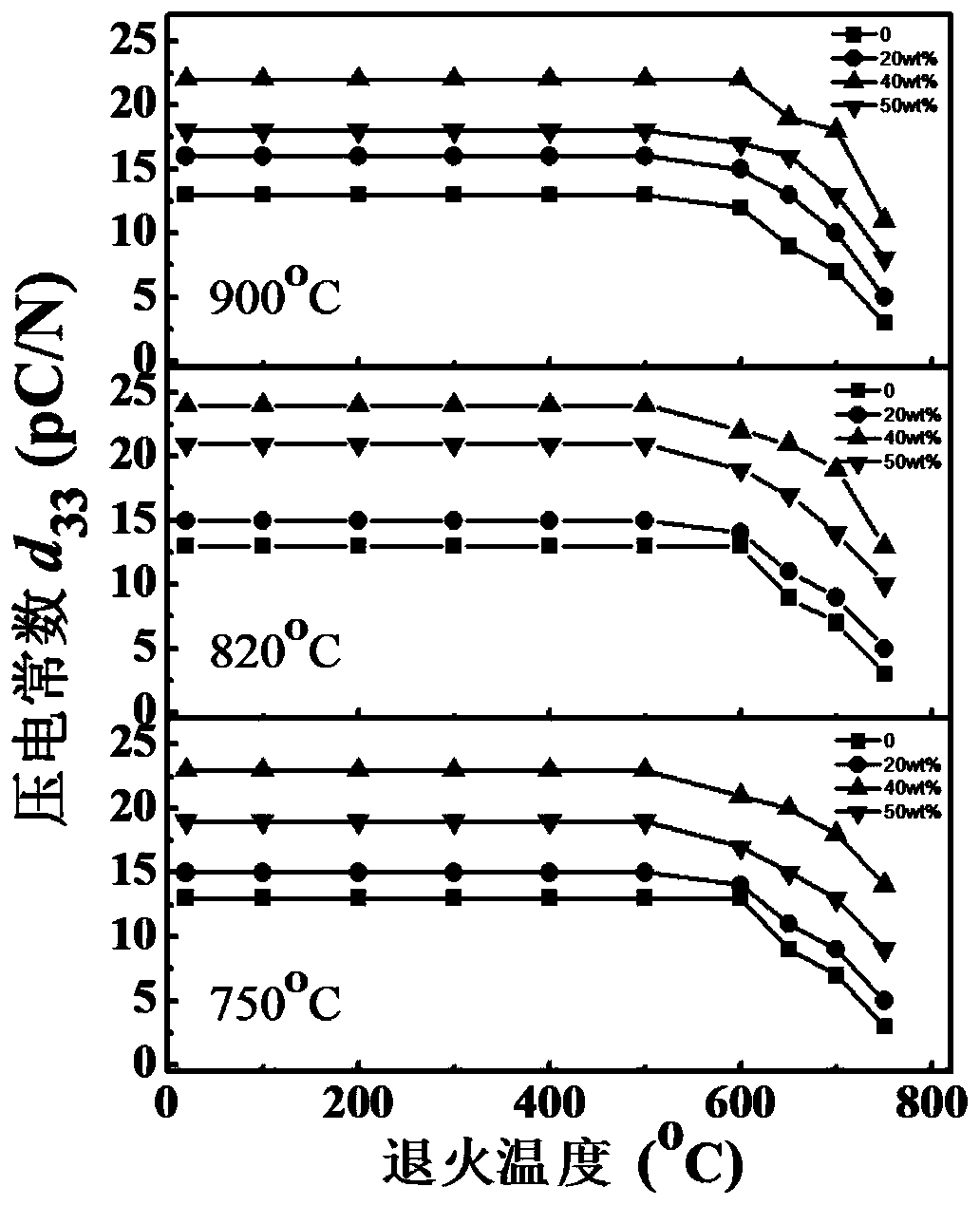

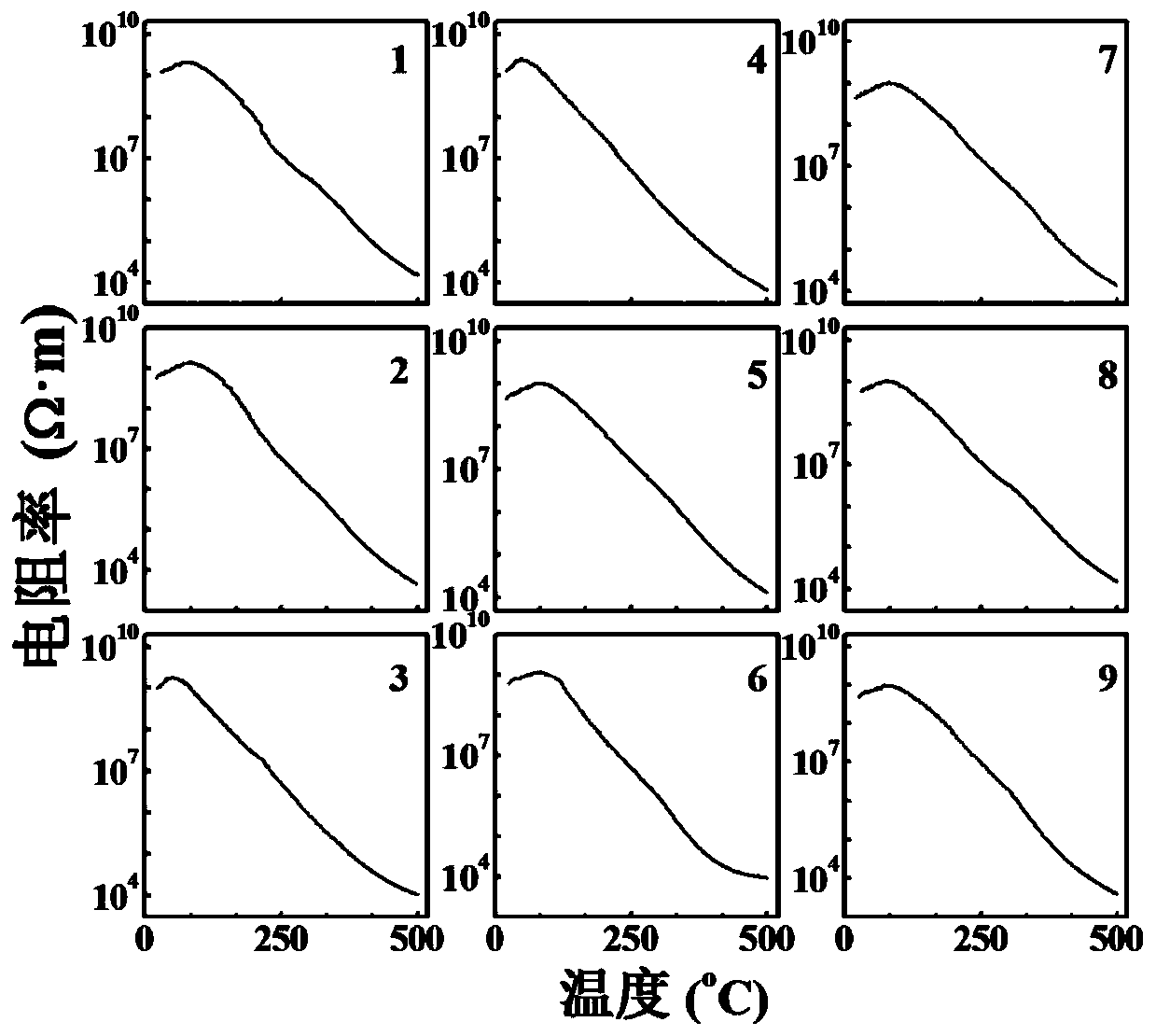

[0032] quasi-static d 33 Tester is to the Bi after the embodiment polarization 3 TaTiO 9 Ceramic sa...

Embodiment 3

[0035] This embodiment uses the BiFeO of embodiment 1 3 Powder and the Bi of Example 2 3 TaTiO 9 Powder preparation Bi 3 TaTiO 9 -20wt% BiFeO 3 For ceramics, the sintering temperature is 750°C.

[0036] The preparation steps are:

[0037] 1. the BiFeO in embodiment 1 3 Bi in ceramic powder and embodiment 2 3 TaTiO 9 Ceramic powder according to Bi 3 TaTiO 9 -20wt% BiFeO 3 Weigh it and put it into a planetary ball mill for low-speed ball milling for 1 hour.

[0038] 2. After ball milling, take out the slurry, dry it, and 3 TaTiO 9 -20wt% BiFeO 3 Add polyvinyl alcohol solution to the powder as a binder, grind it again and press it into a ceramic disc.

[0039] 3. After debinding the pressed ceramic disc at 550°C for 3 hours, raise the temperature to 750°C for sintering at a rate of 80°C / min. temperature to room temperature to prepare ceramic samples. The sample number is No. 1.

[0040] 4. Brush the upper and lower surfaces of the ceramic sheets fired in step 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com