Production method for enhanced GaN transistor

A manufacturing method and technology of gallium nitride, which are applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of small on-resistance and high withstand voltage of gallium nitride transistors, and achieve reduced on-resistance, The effect of reducing the surface electric field and improving the withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] figure 1 The flow chart of the fabrication method of the enhancement mode gallium nitride transistor provided by the embodiment of the present invention. In order to describe the method in this embodiment clearly and systematically, Figure 2-Figure 8 A schematic cross-sectional view of an enhancement-mode gallium nitride transistor during the implementation of the method of the embodiment of the present invention, as shown in figure 1 As shown, the method includes:

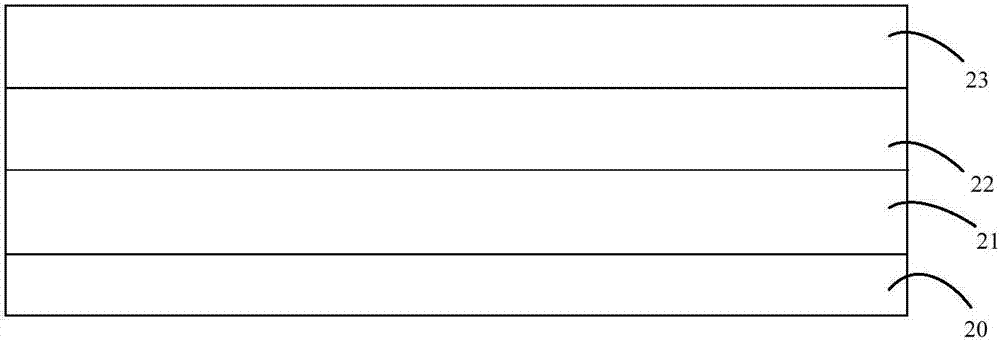

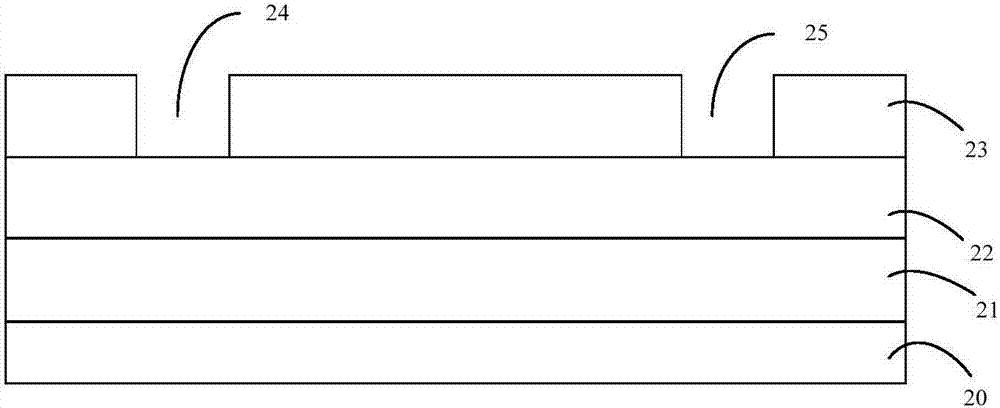

[0024] Step S101, sequentially growing a phosphorus-doped GaN dielectric layer, an aluminum gallium nitride AlGaN dielectric layer, and a silicon nitride Si3N4 dielectric layer on the surface of a silicon substrate;

[0025] Such as figure 2 As shown, a phosphorus-doped GaN dielectric layer, an aluminum gallium nitride AlGaN dielectric layer and a silicon nitride Si3N4 dielectric layer are sequentially grown on the surface of a silicon substrate, and the schematic cross-sectional view after performing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com