A kind of ultra-thin black light-shielding film and processing method thereof

A film and black technology, applied in the field of ultra-thin black light-proof film and its processing, can solve the problems of being unsuitable for small batch, multi-variety processing, occupying large space, and high processing cost, achieving light weight, convenient processing, and production equipment. low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

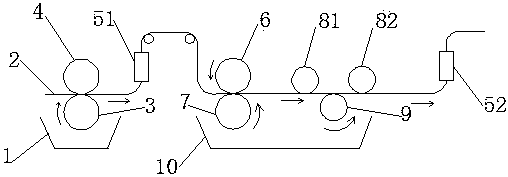

Method used

Image

Examples

Embodiment 1

[0029] A coating made from the following raw materials:

[0030] TPU resin (thermoplastic polyurethane resin, Luoyang Jiming Chemical Co., Ltd., model JM-1019): 20wt%;

[0031] TDI (toluene diisocyanate): 0.1wt%;

[0032] BYK-163 dispersant from BYK, Germany: 0.2wt%;

[0033] TEGO-Glide 410 leveling agent from Tego Germany: 0.1wt%;

[0034] Carbon black: 3wt%;

[0035] Clay: 10wt%;

[0036] Solvent: 66.6wt%, mixed with methyl ethyl ketone and ethyl acetate at a volume ratio of 1:1, prepared by the following method: take each raw material in proportion, after mixing, the various materials are first dispersed with a high-speed disperser for 60 Minutes to make all materials fully mixed, no agglomeration, no precipitation, forming a uniform dispersion, grinding the coating under the condition of passing cooling water through a pin-type sand mill, and wet grinding to a fineness of less than 0.6μm More than 90%, the temperature of the coating during the grinding process is not ...

Embodiment 2

[0047] A coating made from the following raw materials:

[0048] TPU resin (thermoplastic polyurethane resin, Luoyang Jiming Chemical Co., Ltd., model JM-1019): 15wt%;

[0049] TDI (toluene diisocyanate): 0.2wt%;

[0050] German BYK-163 dispersant: 0.4wt%;

[0051] TEGO-Glide 410 leveling agent from Tego Germany: 0.3wt%;

[0052] Carbon black 5wt%;

[0053] Clay: 15wt%;

[0054] Solvent: 64.1wt%, mixed with methyl ethyl ketone and ethyl acetate at a volume ratio of 1:1, prepared by the following method: take each raw material in proportion, after mixing, the various materials are first dispersed with a high-speed disperser for 30 Minutes to make all materials fully mixed, no agglomeration, no precipitation, forming a uniform dispersion, grinding the coating under the condition of passing cooling water through a pin-type sand mill, and wet grinding to a fineness of less than 0.6μm More than 90%, the temperature of the coating during the grinding process is not greater than...

Embodiment 3

[0065] A coating made from the following raw materials:

[0066] TPU resin (thermoplastic polyurethane resin, Luoyang Jiming Chemical Co., Ltd., model JM-1019): 18wt%;

[0067] TDI (toluene diisocyanate): 0.2wt%;

[0068] German BYK-163 dispersant: 0.3wt%;

[0069] TEGO-Glide 410 leveling agent from German Tego: 0.2wt%;

[0070] Carbon black: 4wt%;

[0071] Clay: 13wt%;

[0072] Solvent: 64.3wt%, mixed with methyl ethyl ketone and ethyl acetate at a volume ratio of 1:1, prepared according to the following method: take each raw material in proportion, after mixing, the various materials are mixed and then dispersed with a high-speed disperser for 45 Minutes to make all materials fully mixed, no agglomeration, no precipitation, forming a uniform dispersion, grinding the coating under the condition of passing cooling water through a pin-type sand mill, and wet grinding to a fineness of less than 0.6μm More than 90%, the temperature of the coating during the grinding process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com