Protoporphyrin-zinc aluminum hydrotalcite compound and preparation method and application thereof

A technology of zinc-aluminum hydrotalcite and protoporphyrin, applied in the field of protoporphyrin-zinc-aluminum hydrotalcite compound and its preparation, can solve the problems of strong irritation, gastric acid stimulation and side effects, etc., and achieve simple operation, rich sources, and significant clinical The effect of applying value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of protoporphyrin-zinc-aluminum hydrotalcite compound of the present invention comprises the following steps:

[0038] (1) Preparation of zinc-aluminum hydrotalcite: prepare mixed salt solution of zinc ion and aluminum ion, lye and aqueous solution containing nitrate ion; the mol ratio of zinc ion and aluminum ion in the described mixed salt solution is 2:1, so The amount of the substance of the hydroxide ion in the alkali lye is 2 times of the sum of the amount of the zinc ion and the aluminum ion substance;

[0039] At a temperature of 15-30 °C under nitrogen protection and stirring conditions, the above mixed salt solution and alkali solution are dropped into the aqueous solution containing nitrate ions at the same time, and after the addition is completed, the temperature is raised to 50-70 °C and aged for 1-3 hours. After aging, pour the reaction solution into a high-temperature and high-pressure reactor, and conduct a hydrothermal reaction at ...

Embodiment 1

[0050] (1) Synthesis of nitrate-type zinc-aluminum hydrotalcite: Weigh 1.19gZn(NO 3 ) 2 ·6H 2 O (4mmol), 0.75gAl (NO 3 ) 3 9H 2 O (2mmol), dissolved in 40ml of water boiled to remove carbon dioxide, dubbed a mixed salt solution. Weigh 0.486g (12mmol) NaOH, dissolve in 40ml decarbonated water, and make lye. Weigh 1g anhydrous NaNO 3 , dissolved in 20ml of carbon dioxide-free water, dubbed an aqueous solution. At room temperature (15°C-30°C), under the condition of nitrogen protection and strong mechanical stirring, slowly drop the mixed salt solution and alkali solution into NaNO 3 In the aqueous solution, the dropping speed is strictly controlled, so that the dropping speed of the mixed salt solution and the lye are exactly the same. After the dropwise addition, raise the temperature of the reaction solution to 50-70°C and age for 1-3h. After aging, pour the reaction solution into a high-temperature and high-pressure reactor, heat it in water at 120°C for 6-12 hours, ...

Embodiment 2

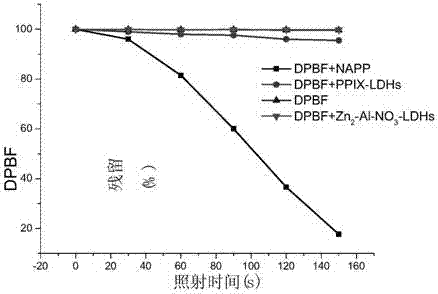

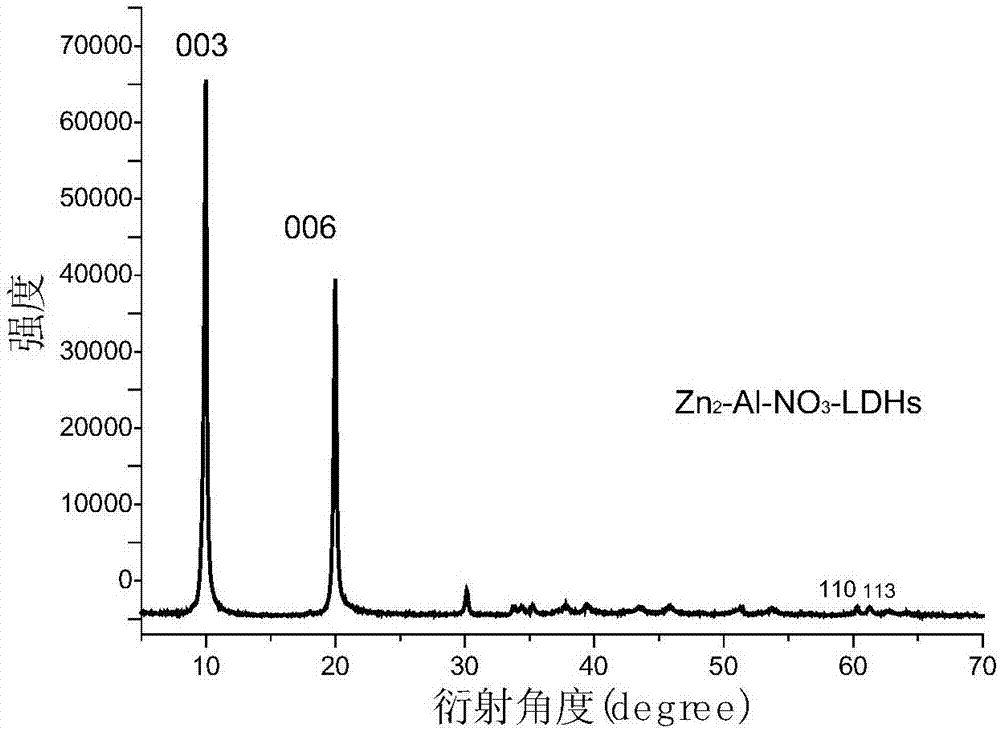

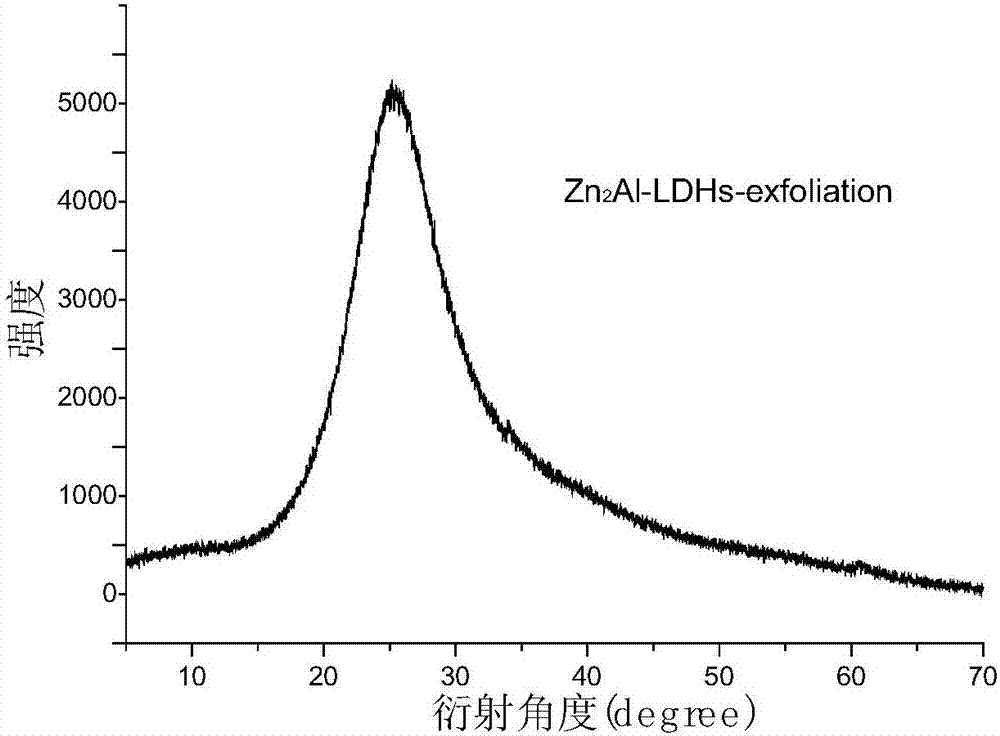

[0054] This embodiment tests the X-ray diffraction peaks of nitrate-type zinc-aluminum hydrotalcite and zinc-aluminum hydrotalcite nanosheet gel after peeling off, see respectively figure 1 with 2 . from figure 1 It can be seen that the prepared material is a typical zinc-aluminum hydrotalcite.

[0055] According to the document "Chemical Communications", 2014, 50(70): 10130-2, it can be known that if the hydrotalcite is successfully stripped into a single sheet in formamide, and the formed gel is subjected to X-ray diffraction, the characteristic peak of the hydrotalcite ( 003), (006) will disappear, and a broad and weak diffraction peak will appear around 2θ equal to 25°. Spread the formed gel evenly on the glass slide, try to ensure that the gel surface is as smooth as possible, and perform XRD characterization. The results are shown in figure 2 , which is completely consistent with the literature reports, indicating that zinc-aluminum hydrotalcite nanosheets have been...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com